Gear micro-texture flow control cold extrusion forming die and preparation method thereof

A forming die and micro-texturing technology, applied in metal extrusion dies, metal extrusion forming tools, metal extrusion, etc., can solve the problem of insufficient filling in the toothed area, difficult metal flow, and large forming force in the toothed area, etc. To solve the problem of slow flow of blanks, improve the quality of gear forming, and improve the filling state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

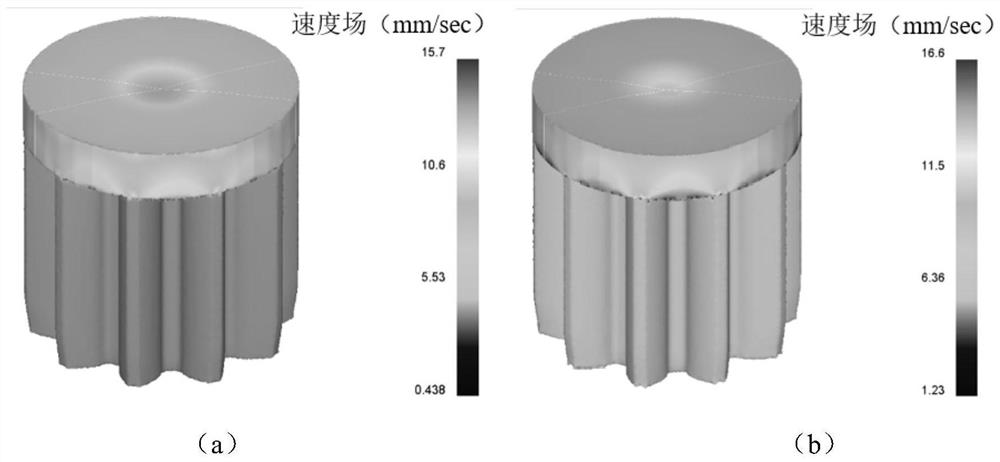

[0032] A preparation method according to the gear micro-texture control flow cold extrusion forming die, comprising the following steps:

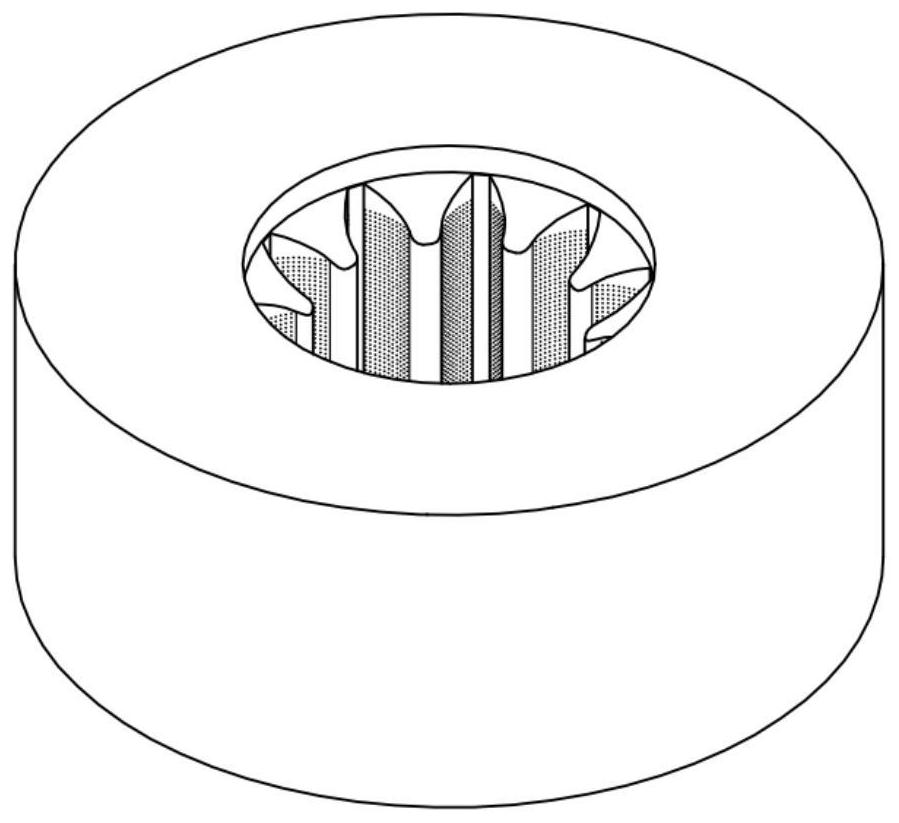

[0033] According to the analysis of the structure of the gear die, the area where the blank is difficult to fill is determined, and the back of the tooth in the tooth-shaped area of the tooth-shaped die is determined as the optimized area for micro-texture flow control forming;

[0034] Place the gear mold in an ultrasonic cleaning machine for 15 minutes of ultrasonic cleaning to remove stains on the surface of the mold, take it out after cleaning, and place it to dry;

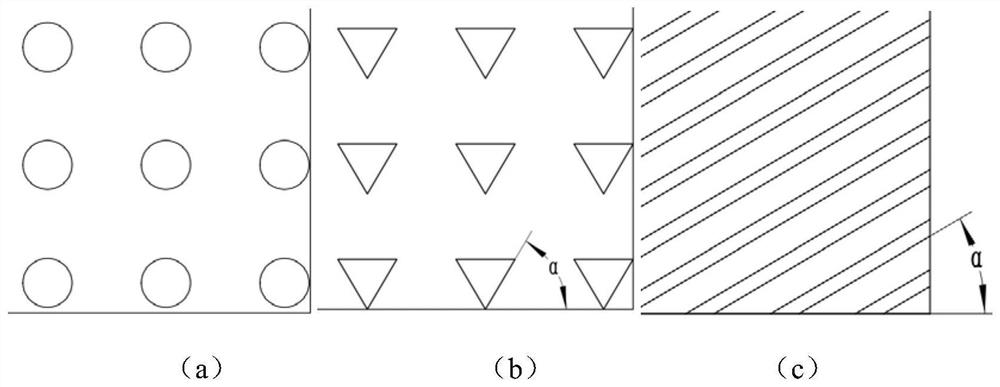

[0035] Clamp the gear cold extrusion forming mold to the laser workbench, set the laser processing parameters, and prepare pit micro-texture, groove micro-texture or Triangular micro-texture;

[0036] Ultrasonic cleaning was performed on the processed gear cold extrusion die to remove the slag in the micro-texture.

[0037] When preparing the pit micro-texture at the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com