Dust and ash removal device for waste incineration

A technology for cleaning ash device and waste incineration, which is used in transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of inability to remove dust, easy adhesion of dust, difficult to clean inside the device and filter structure, etc. To achieve the effect of good use, to achieve the cleaning function, to achieve the effect of the exhaust function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

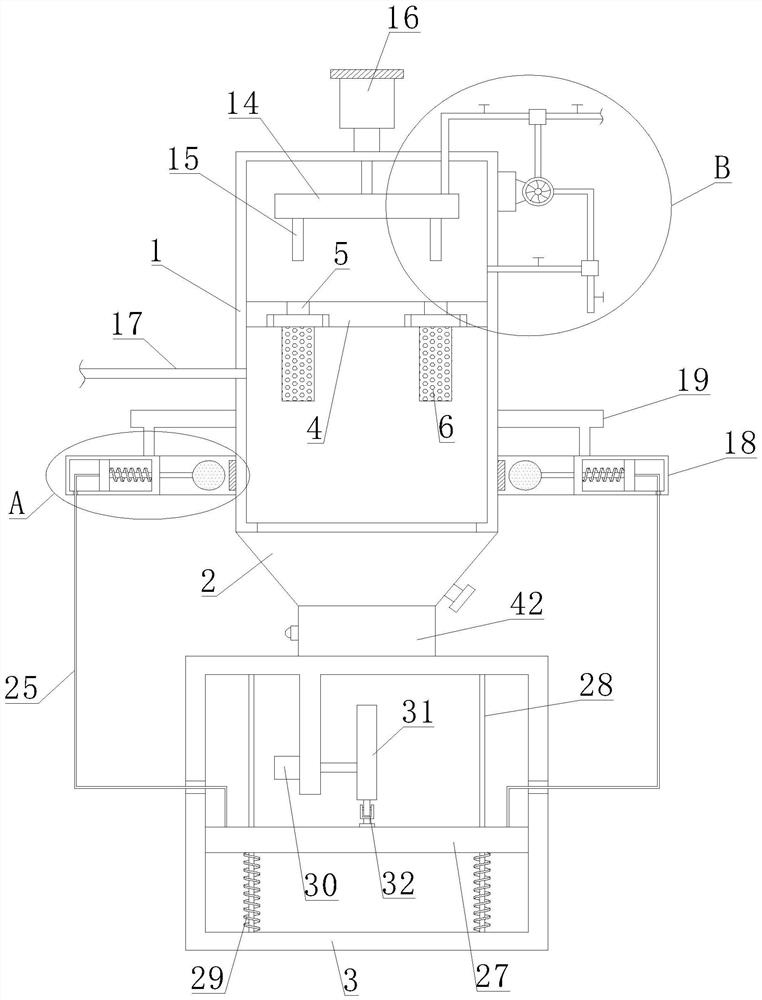

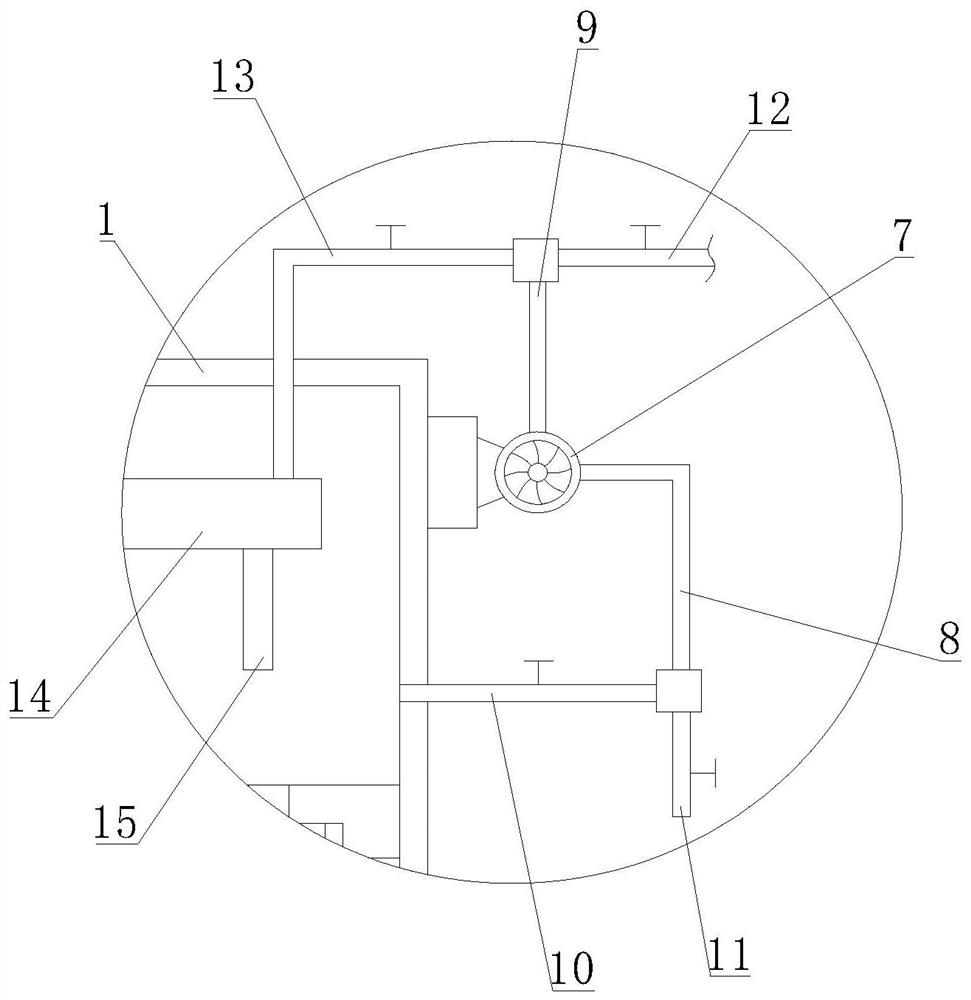

[0030] like Figure 1-5As shown, the present invention proposes a dust removal and ash removal device for garbage incineration, including a dust removal box 1, an ash discharge bucket 2, a fixed box 3 and a dust discharge pipe 33, and the ash discharge bucket 2 is fixedly arranged at the bottom of the dust removal box 1 , the ash discharge hopper 2 collects the dust generated in the dust filtering process, the fixed box 3 is located under the dust removal box 1 and is fixedly connected with the ash discharge hopper 2 through bolts, and the dust discharge pipe 33 is fixedly arranged on the ash discharge hopper 2, and the dust discharge pipe 33 is used to discharge the dust in the dust discharge hopper 2, and the dust discharge pipe 33 is provided with a valve, the valve is used to control the discharge of dust, and the dust discharge hopper 2 is provided with a reminder cleaning mechanism 42, which is used to Remind the operator to clean up the accumulated dust in the ash disch...

Embodiment 2

[0034] like Image 6 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, the reminder cleaning mechanism 42 includes a detection chamber 34, a bearing plate 35, a pressure sensor 36, a third spring 37, a buzzer 38 and a processor; The inner bottom of the bucket 2 is provided with a detection cavity 34, and the bearing plate 35 is horizontally arranged in the detection cavity 34, and the dust generated in the filtering process falls and gathers on the bearing plate 35, and the weight of the dust makes the bearing plate 35 drop, and the third spring 37 is vertically arranged in the detection chamber 34 and connected with the bottom of the bearing plate 35, the third spring 37 is used to lift the bearing plate 35 to return to its original position after unloading; the pressure sensor 36 is fixed and installed in the detection chamber 34 by bolts Inside, and the pressure sensor 36 is below the bearing plate 35, when the internal dust reaches a certa...

Embodiment 3

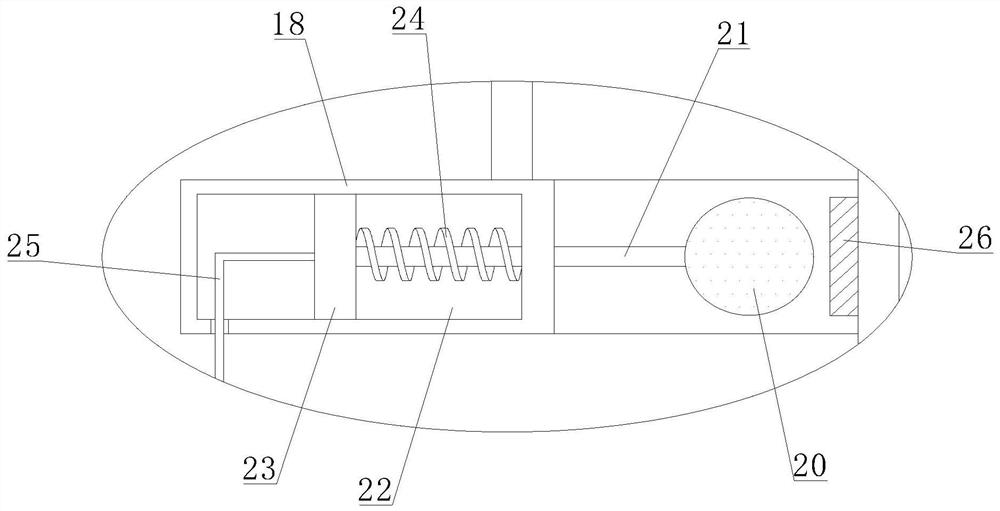

[0036] like Figure 7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a second limiting cavity 41 is opened in the knocking ball 20, and a second sliding block 39 is slidably arranged in the second limiting cavity 41, and the second limiting cavity The cavity 41 plays a limiting role on the second slider 39, and the second slider 39 slides in the second limiting cavity 41; the movable rod 21 extends into the second limiting cavity 41 and is connected with the second slider 39, The second slide block 39 is equipped with a fourth spring 40 on the side facing away from the second slide block 39. When the knocking ball 20 hits the dust removal box 1, the second slide block 39 slides in the second spacer cavity 41, and the fourth spring 40 The spring 40 is elastically deformed to play a buffering role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com