Sea buckthron oil slow-release diaper

A technology of seabuckthorn oil and diapers, which is applied in the field of diapers, can solve the problems of slow liquid absorption rate, uneven distribution of liquid, dryness, roughness, and diaper rash, etc., and achieve the effect of fast absorption rate and large absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

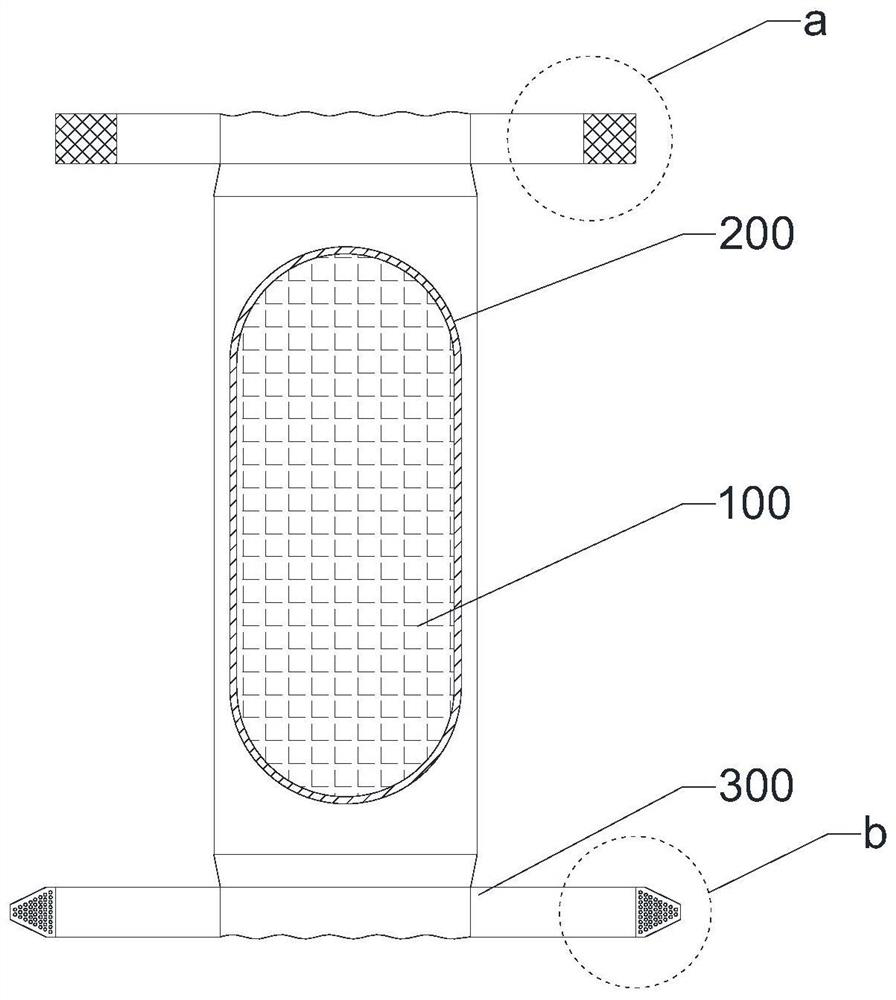

[0045] like Figure 1-7 as shown,

[0046] A sea buckthorn oil extended-release diaper comprising:

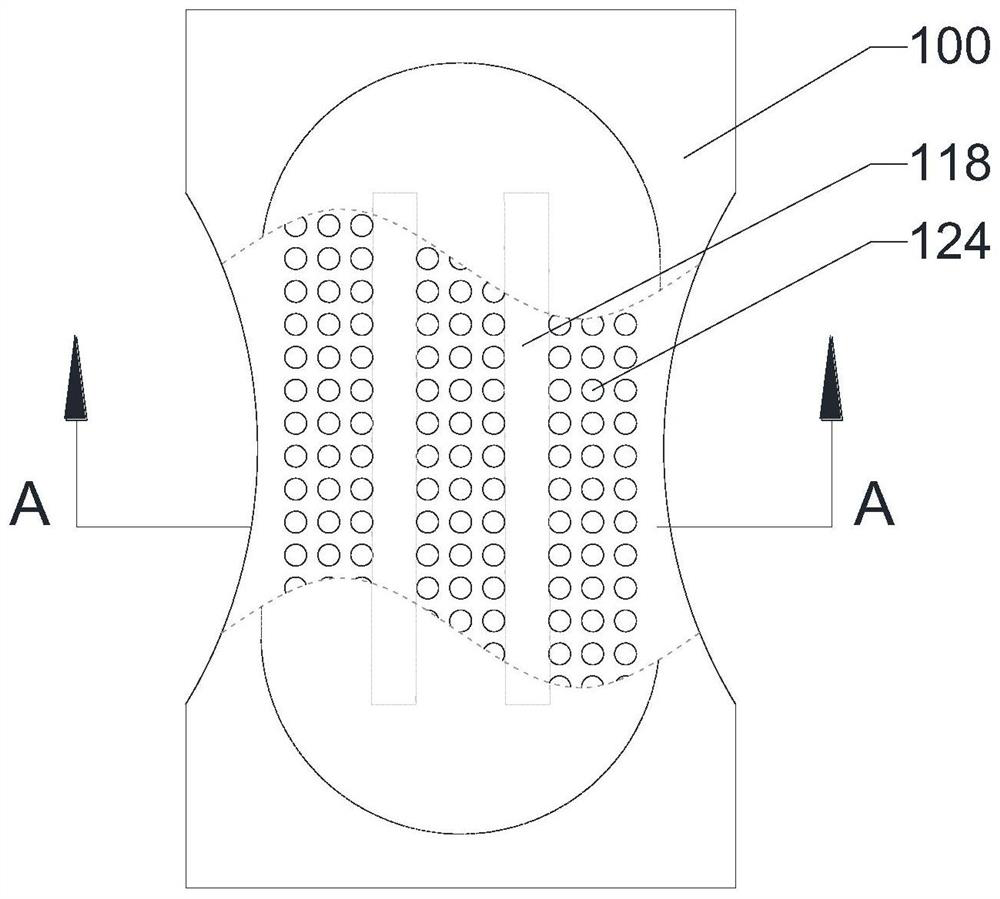

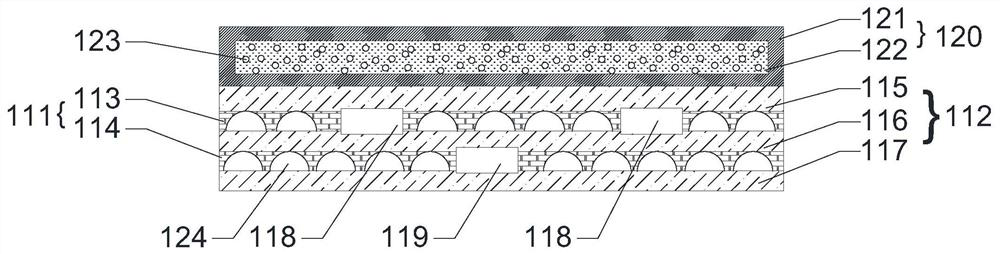

[0047] Double-layer absorbent core 100, the double-layer absorbent core 100 includes an absorbent layer 110 and a skin-friendly layer 120:

[0048] The absorbent layer 110 is used to realize the function of absorbing liquids such as urine, and specifically includes: an absorbent core body 111 and liquid-absorbing parts 112 alternately arranged above and below the absorbent core body 111;

[0049] The absorbent core main body 111 is composed of a first absorbent layer 113 and a second absorbent layer 114 from top to bottom. The first absorbent layer 113 and the second absorbent layer 114 are made of water-absorbent capsules 124 made of SAP pellets. The seabuckthorn oil slow-release layer is coated with the same composition as the seabuckthorn oil slow-release ball, and is made by spraying dichloromethane solution.

[0050] The first absorbent layer 113 and the second absorben...

Embodiment 2

[0067] The structure of embodiment 2 is the same as that of embodiment 1, the difference is that the preparation process of seabuckthorn oil microspheres is different, and its preparation method is as follows: get 15 parts of PLA, 5 parts of polyethylene glycol and add 20 parts of dichloromethane to dissolve and obtain PLA solution, and then Add 1 part of seabuckthorn oil to the PLA solution, mix well, and spray dry to obtain seabuckthorn oil sustained-release microspheres, which are stored in a desiccator for later use; spray drying operating conditions: air inlet temperature 125°C, atomization pressure 0.6bar, peristaltic pump Speed 15RPM.

Embodiment 3

[0069] The structure of embodiment 3 is the same as that of embodiment 1, the difference is that the preparation process of seabuckthorn oil microspheres is different, and its preparation method is as follows: get 10 parts of PLA, 8 parts of polyethylene glycol and add 20 parts of dichloromethane to dissolve and obtain PLA solution, and then Add 1 part of seabuckthorn oil to the PLA solution, mix well, and spray dry to obtain seabuckthorn oil sustained-release microspheres, which are stored in a desiccator for later use; spray drying operating conditions: air inlet temperature 115°C, atomization pressure 0.6bar, peristaltic pump Speed 12RPM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com