Seed fertilizer coating and application system and method of coating and application

A coating and hanger technology, applied in botany equipment and methods, seed coating/seed dressing, layering/coating fertilizer, etc., can solve the problems of tobacco leaf seedling labor, seed breaking, high cost, etc., to achieve Fertilizer and pesticide coating slow release and automatic intelligent precise control, ensuring stability and effectiveness, quantitative and accurate application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

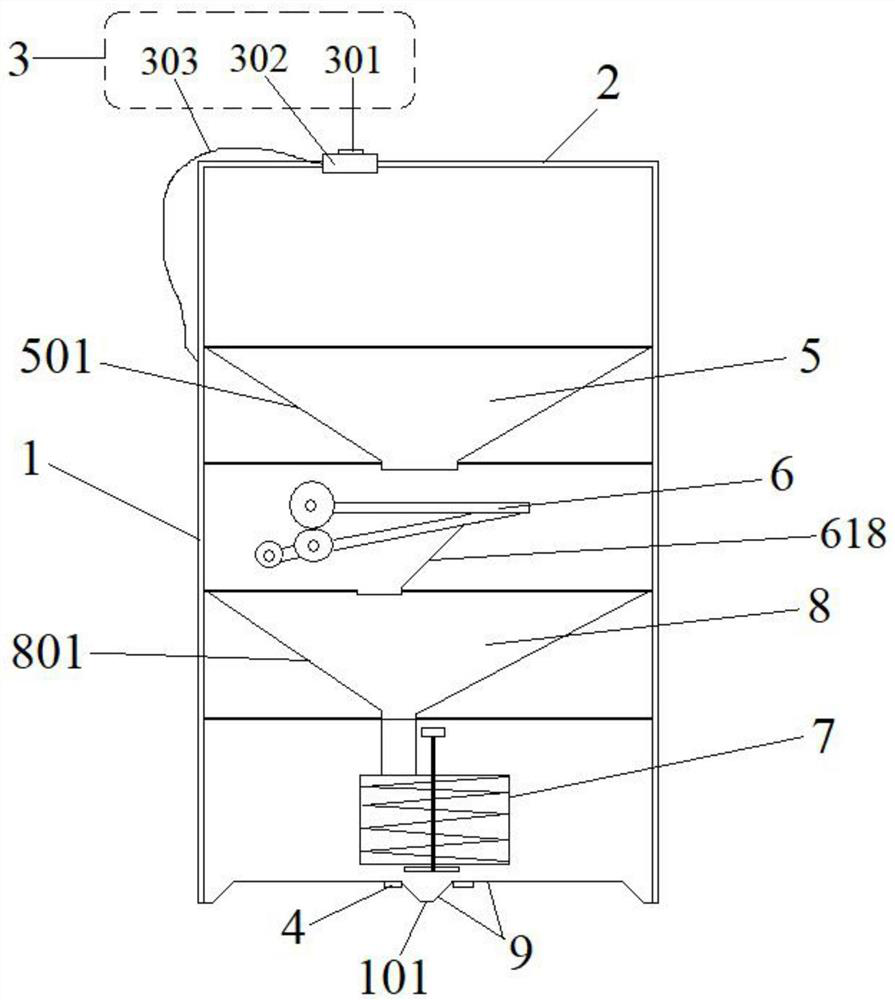

[0098] like Figure 1-2 As shown, a seed fertilizer coating and application system includes a box body 1 and a handle 2 arranged on the upper end of the box body 1 . The inner cavity of the box body 1 is sequentially provided with a feeding box 5 , a wrap-around coating device 6 and a discharging box 8 from top to bottom. The discharge port of the feeding box 5 is communicated with the feeding port of the roll-on coating device 6 . The discharge port of the roll-on coating device 6 communicates with the feed port of the discharge box 8 . A control discharger 7 is also provided at the discharge port of the discharge box 8 .

Embodiment 2

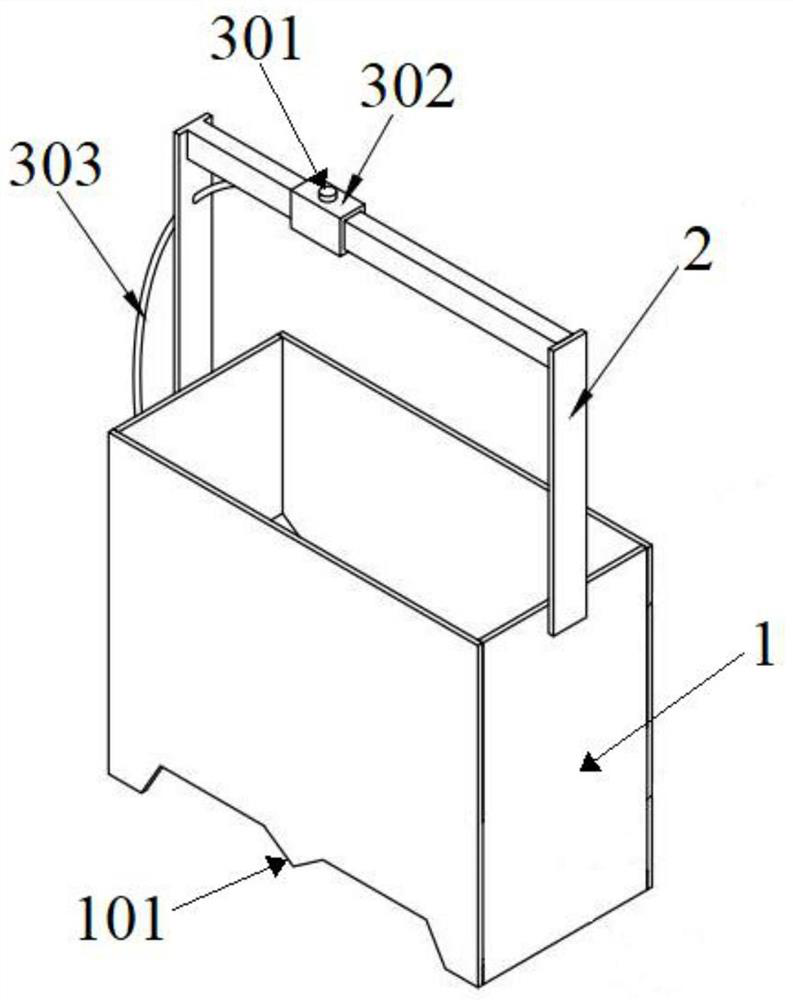

[0100]Example 1 is repeated, except that the system also includes a power supply device 3 . The power supply device 3 includes a power button 301 , a power supply 302 and a connection line 303 . The power button 301 is arranged on the handle 2 . The power supply 302 is arranged on the box body 1 or the handle 2 . The power supply 302 is independently connected to the feeding box 5 , the roll-on coating device 6 , and the control discharger 7 through connection lines 303 . That is, the power supply 302 independently controls the feed box 5, the roll-on coating device 6, the start and stop of the discharger 7 and the opening and closing of their respective inlet and outlet ports through the connection line 303.

Embodiment 3

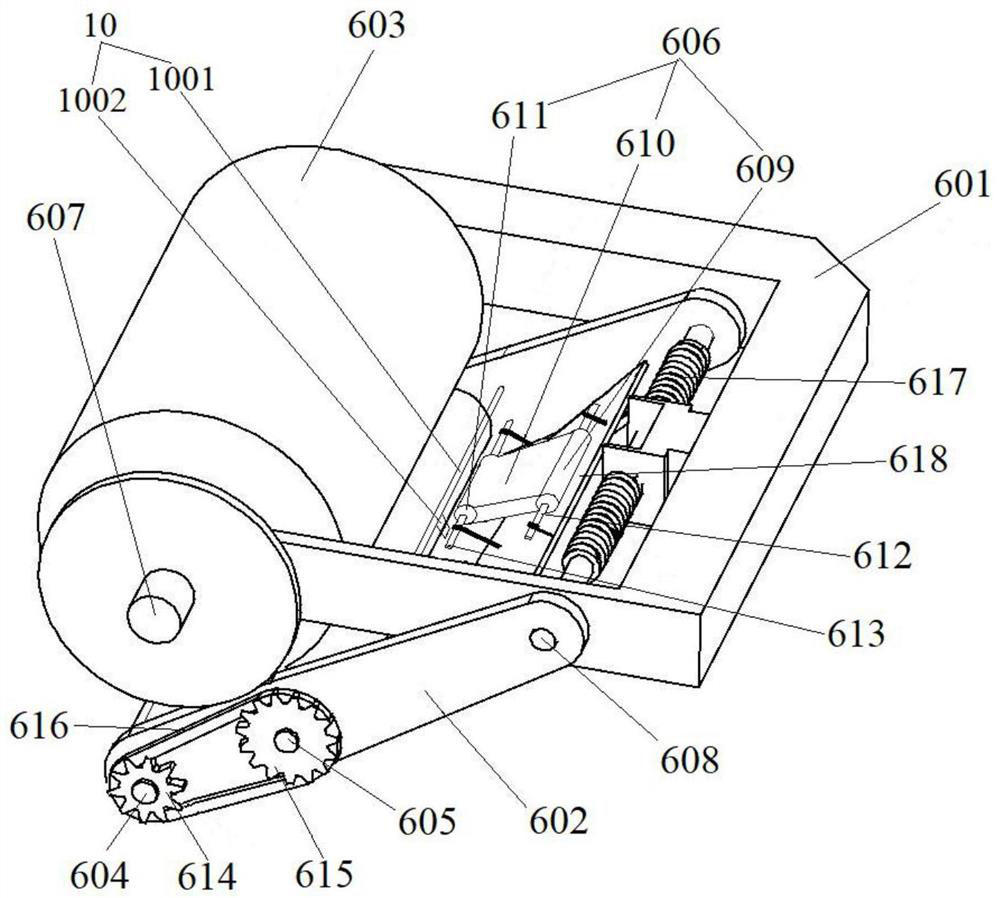

[0102] Repeat Example 2, as image 3 As shown, the roll-up coating device 6 includes a clothes roll rack 601 , a clothes guide rack 602 , a clothes roll 603 , a first clothes guide shaft 604 , a second clothes guide shaft 605 and a material guide belt conveyor 606 . The top end of the clothes guide rack 602 is movably connected with one end of the clothes roll rack 601 . The clothes roll 603 is disposed at the other end of the clothes roll rack 601 . The first clothes guide shaft 604 is disposed at the bottom end of the clothes guide rack 602 . The second clothes guide shaft 605 is disposed on the clothes guide rack 602 and located on the upper side of the first clothes guide shaft 604 . The material guide belt conveyor 606 is arranged on the clothes guide rack 602 and is located on the upper side of the second clothes guide shaft 605 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com