Press forming method

A technology of stamping forming and formed products, which is applied in the field of stamping forming, and can solve problems such as cracks, defects, and wrinkle forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] Since specific press forming experiments were performed on the effects of the press forming method of the present invention, they will be described below.

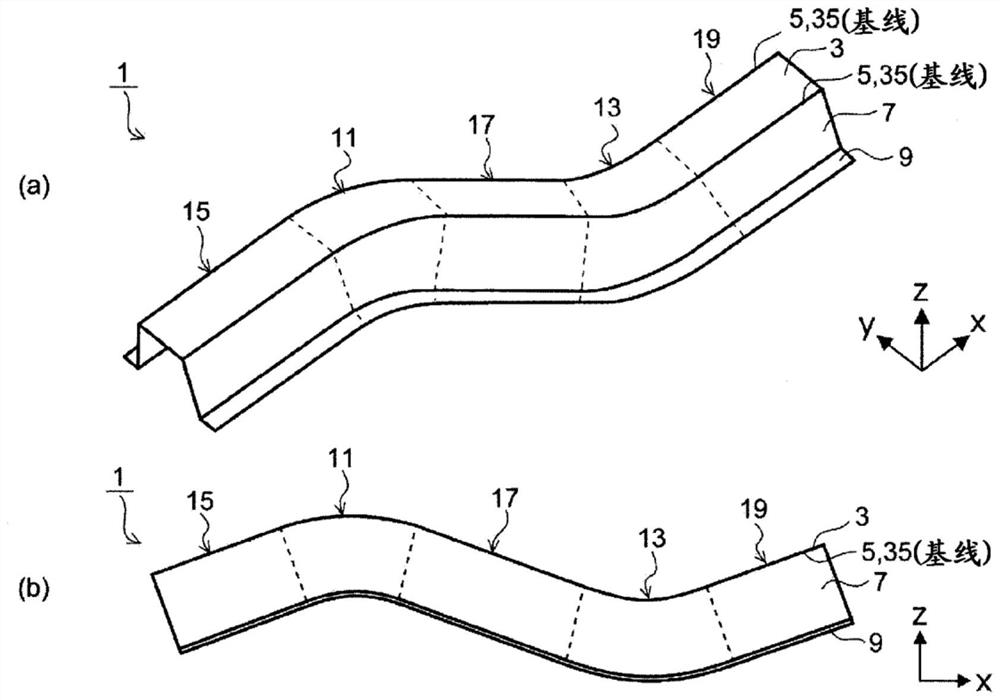

[0079] Assuming that the experiment is stamping forming such as Figure 14 and Figure 15 As shown, an experiment of a press-formed product 1 having a hat-shaped cross section having a convexly curved portion 11 curved convexly in a height direction and a concavely curved portion 13 curved concavely is shown. In the press-formed product 1 , the curvature radius of curvature (curvature radius) of the convex curved portion 11 and the curvature radius of curvature of the concave curved portion 13 in the Z-axis direction are both R150. In addition, in the angle formed by the top plate side ridge line portion 5 and the forming direction in the vertical wall portion 7 of each of the straight portions 15, 17, 19 provided adjacent to the longitudinal direction of the convexly curved portion 11 and the concavely curved port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com