Boiler temperature adjusting method and system based on numerical differentiation

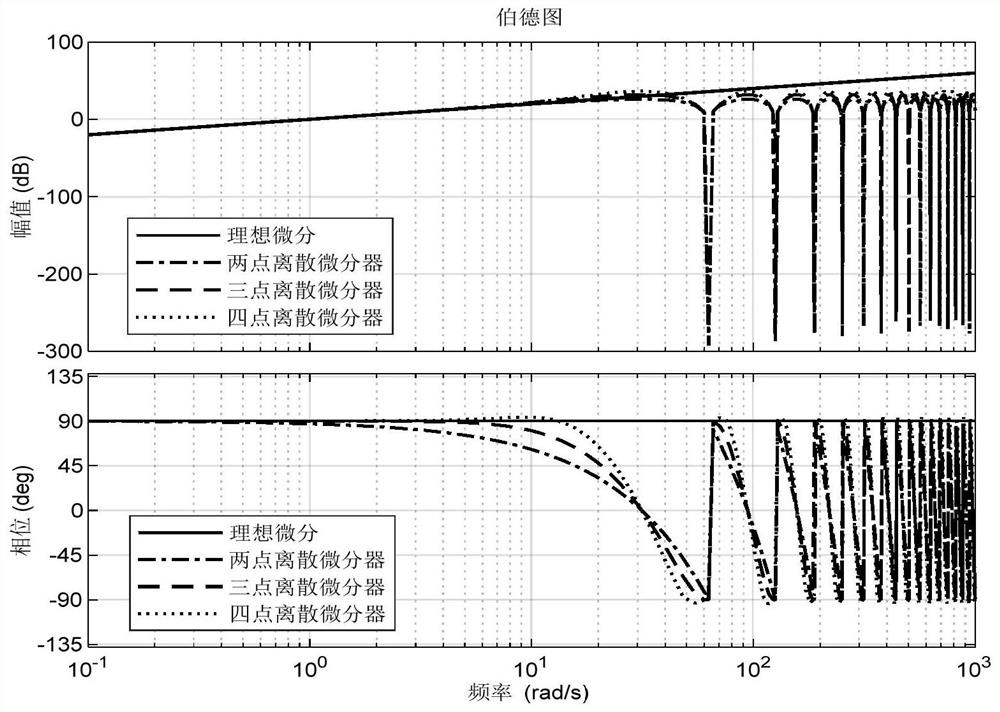

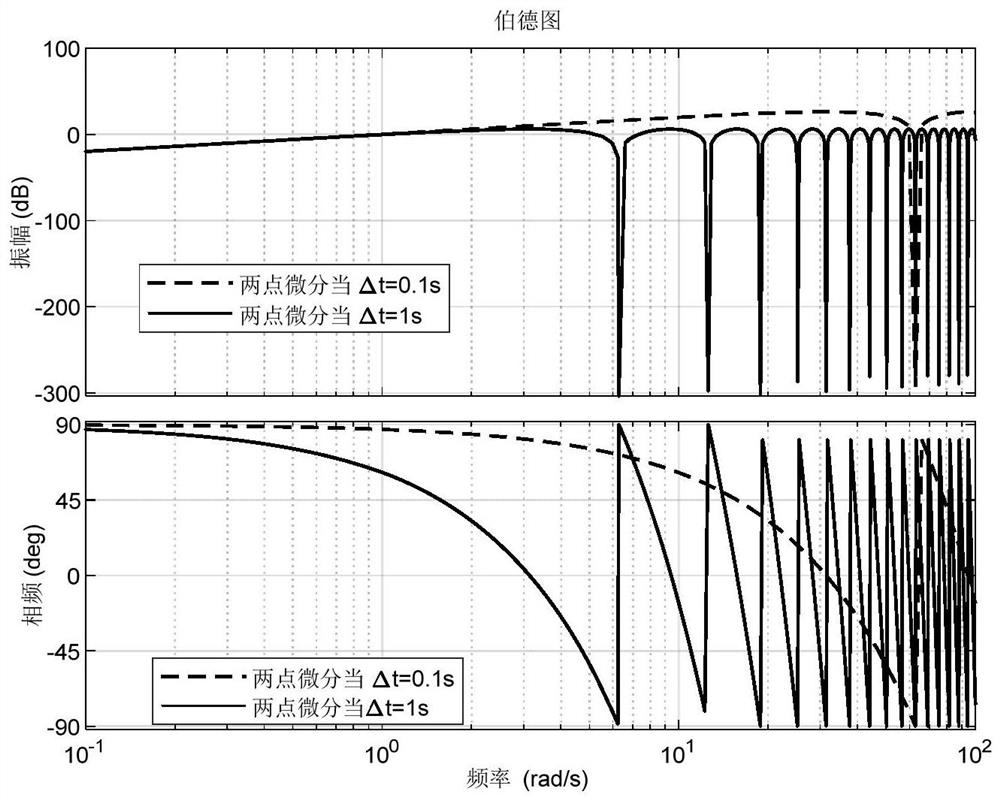

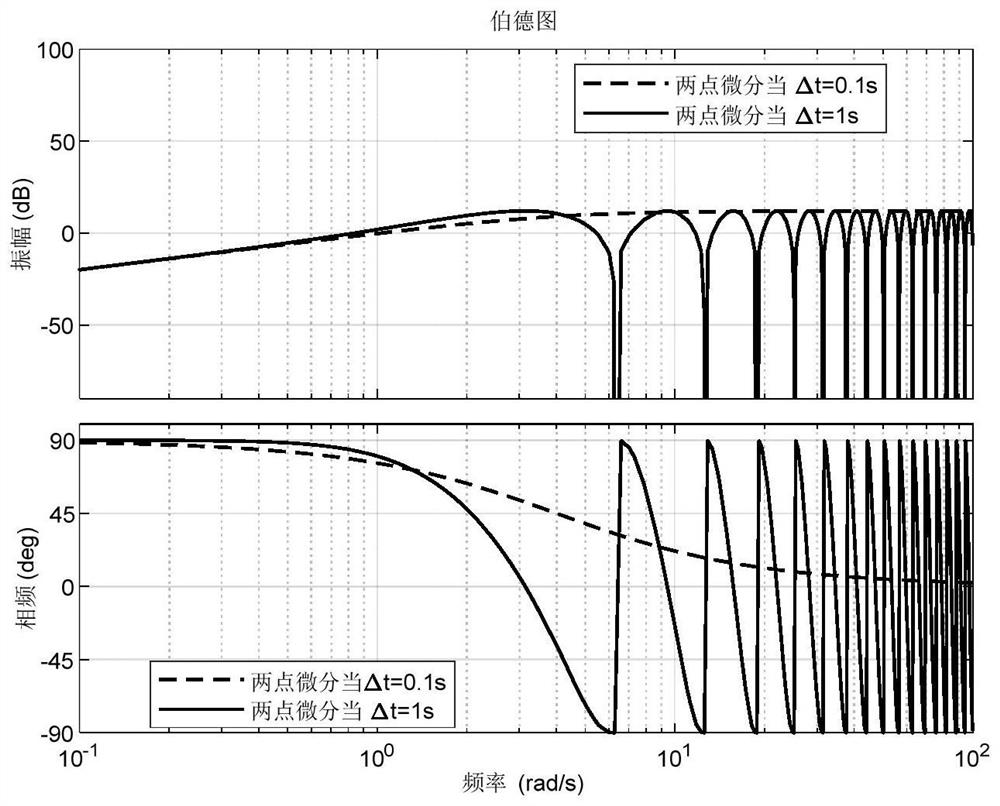

A technology of numerical differentiation and adjustment method, applied in control/regulation systems, temperature control, instruments, etc., can solve the problems of complex realization process of differentiator, large amount of calculation, poor control effect, etc., and achieve good effect of suppressing high-frequency noise , high accuracy, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0086] At present, the boiler temperature control system generally adopts PID control. The present invention replaces the differential link of traditional PID control with a discrete differentiator, obtains a new type of PID controller with different structure, and applies it to the boiler temperature control system. The structure of the boiler temperature control system like Figure 5 As shown, the controlled object in this system is a heat exchanger with obvious inertia. In this example, two inertia links are connected in series to realize this characteristic.

[0087] The boiler temperature control system model is as follows Image 6 . The system is a closed-loop system, and the controlled quantity is temperature. The system consists of a comparator, a PID controller, a three-position relay, an actuator, a heat exchanger and a temperature sensor. When the user has a demand for hot water, the actuator (valve) of the boiler temperature control system is opened, and the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com