Numerical Control Positioning and Locking System and Working Process of Suspension Freight Three-way Turnout Beam Changing Beam

A technology of three-opening turnout and locking system, which is applied to roads, tracks, buildings, etc. It can solve the problem of precise positioning and locking of open box track beams that cannot be changed, and achieves improved positioning accuracy, reduced impact, and stable train operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

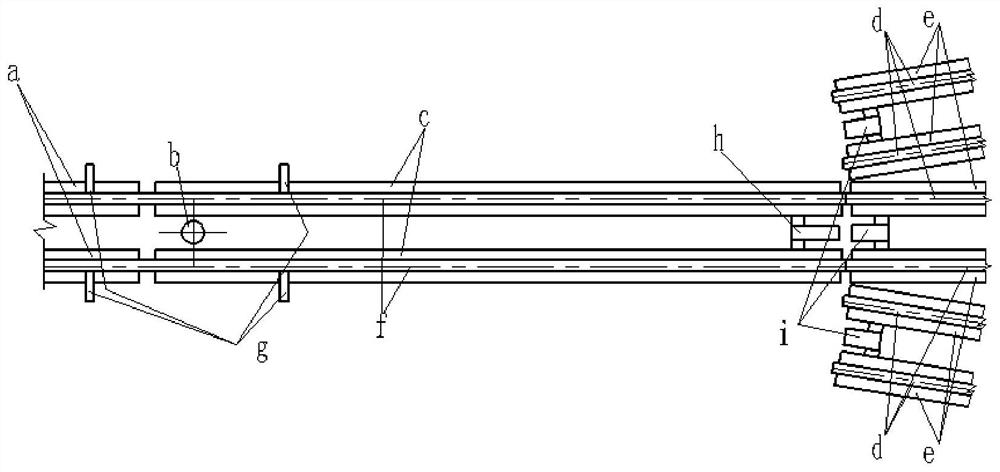

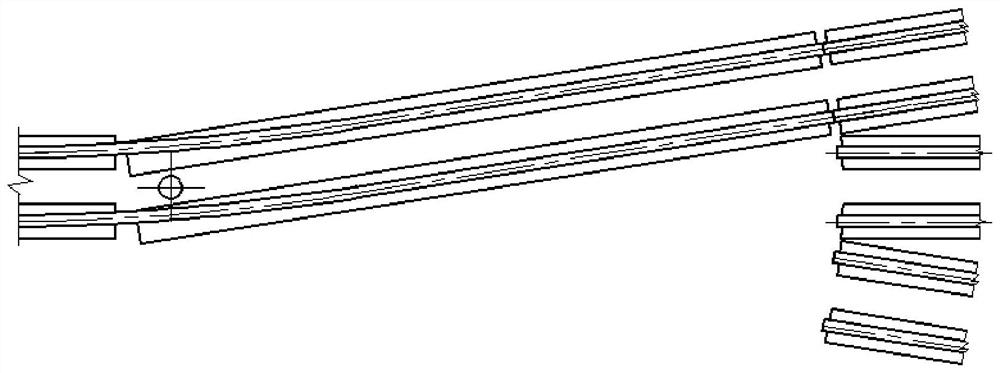

[0074] Such as Figure 1-2 shown in figure 1 In the structural schematic diagram of the suspended freight monorail three-opening turnout, the fixed monorail open box track beam a is two I-shaped beams ( Figure 1-2 Simplified in , the same below), the line-changing monorail open box track beam c is also two I-shaped beams arranged in parallel in space; the three-track open box track beam e is composed of six mutually fixed The two I-shaped girders in the center of the three-track open box track beam e are arranged in parallel in space; the two I-shaped girders on both sides are respectively arranged in parallel in space; the central I-shaped girder and the two sides The included angle between the I-shaped girders is just equal to the line change angle of the turnout. The two change-line rails f are respectively placed on the upper surface of the lower floor inside the I-shaped girder (inside the vertical plate of the I-shaped girder) of the fixed monorail open box track beam...

Embodiment 2

[0094] The invention provides a working process of a numerically controlled positioning and locking system for a suspended freight three-way turnout beam, which is divided into two parts: an installation and debugging process and a working process.

[0095] 1. Installation and debugging process

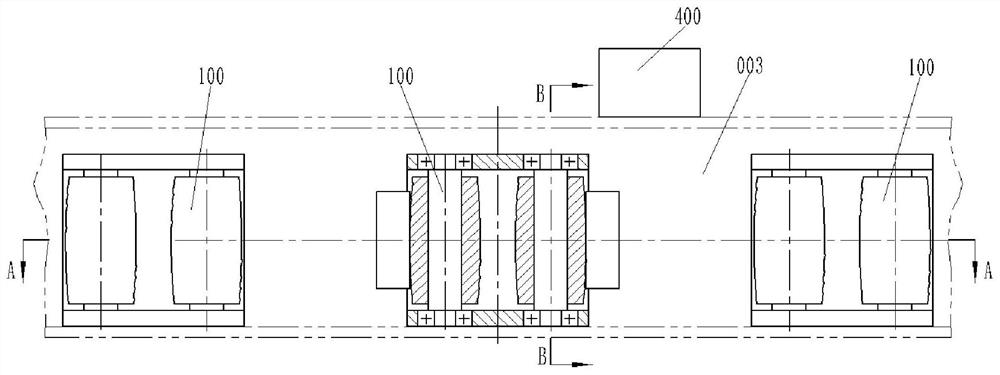

[0096] 1) Median working point setting

[0097] attached Figure 1 to Figure 11 Shown is the positioning and locking state of the CNC positioning and locking system of the suspended freight three-way turnout beam. At the same time, the servo motor A207 and the servo motor B307 are reversed, and the shaft screw A210 and the shaft are driven by the reducer A208 and the reducer B308 respectively. The lead screw B310 rotates in the opposite direction, and then drives the nut A211, the wedge A212 and the nut B311, and the wedge B312 to move away from the double-roller positioning block 100 until the position of the wedge A212 and the wedge B312 does not affect the line-changing monorail o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com