Tufting machine for producing ground elastic lawn

A technology of a tufting machine and a bouncing pad is applied in the field of ground bouncing pad production equipment, which can solve problems such as poor smoothness of the lawn carpet surface, and achieve the effects of smoothing the carpet surface, reducing the upward movement of yarns, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-7 The application is described in further detail.

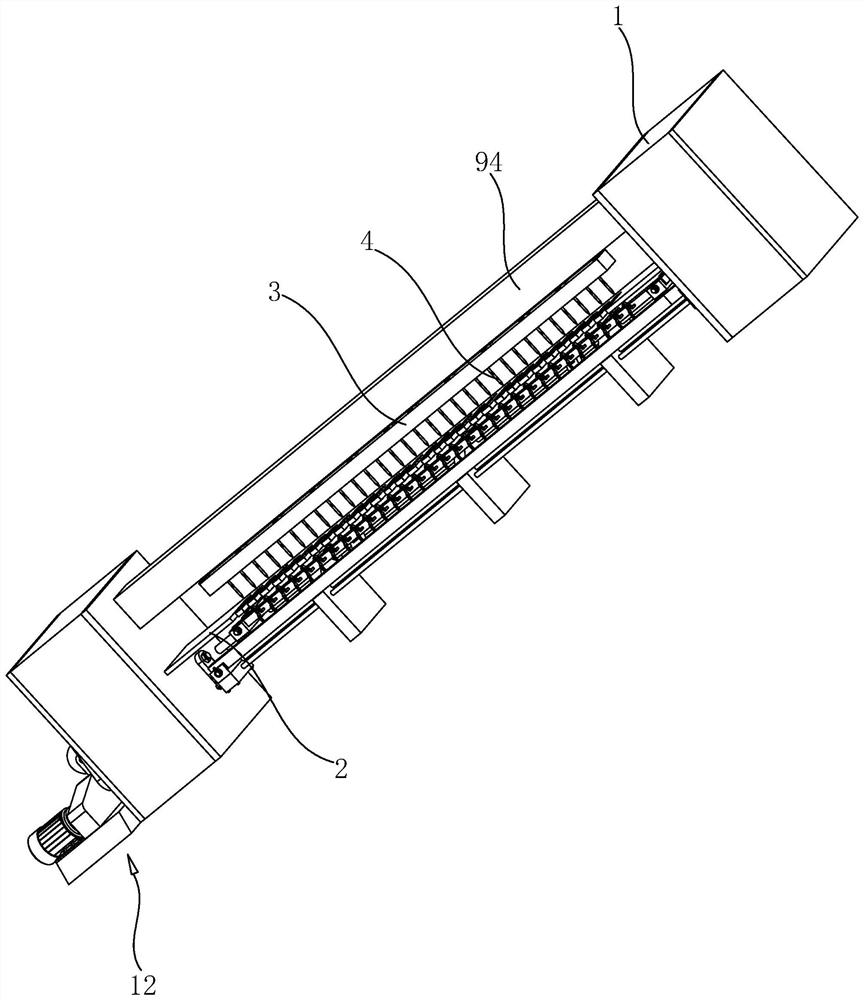

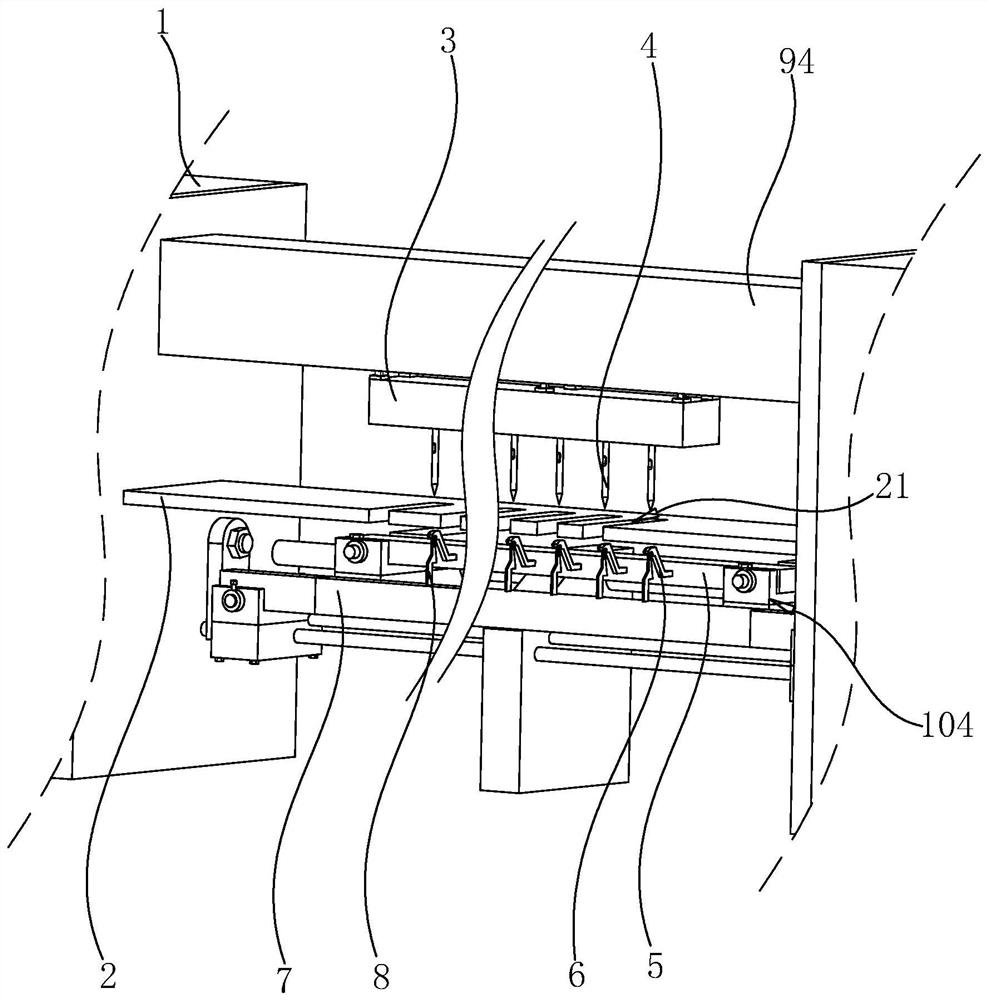

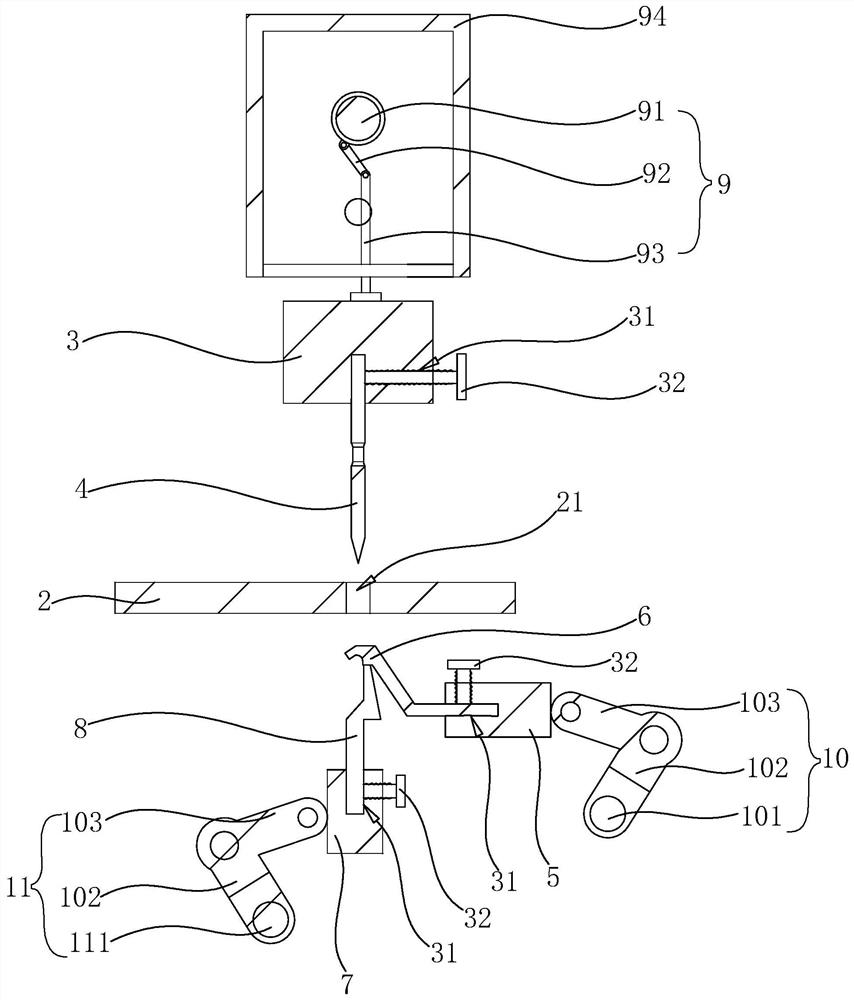

[0041] The embodiment of the present application discloses a tufting machine for floor spring production. refer to figure 1 , figure 2 , a kind of tufting machine for the production of ground springs comprises a frame 1, a support plate 2, a needle seat 3, a needle 4, a main hook base 5, a main hook knife 6, an auxiliary hook base 7, and an auxiliary hook knife 8, The support board 2 is erected on the frame 1, the needle base 3 is arranged in parallel directly above the support board 2, and the needles 4 are multiple and installed at equal intervals on the side of the needle base 3 close to the support board 2, on the support board 2 Matching the position of the needle 4, there are a plurality of holes 21 for the needle 4 to pass through. The sub-hook base 7 is located under the support plate 2. The number of the sub-hook knives 8 is the same as that of the needle 4 and is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com