Pollution-free clean taking-out method after production of titanium sponge

A non-polluting, titanium sponge technology, applied in the field of titanium sponge production, can solve the problems of secondary pollution of titanium lumps, easily scattered on wall-climbing titanium and titanium lumps, etc., so as to improve safety, improve yield and appearance quality. , the effect of preventing flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

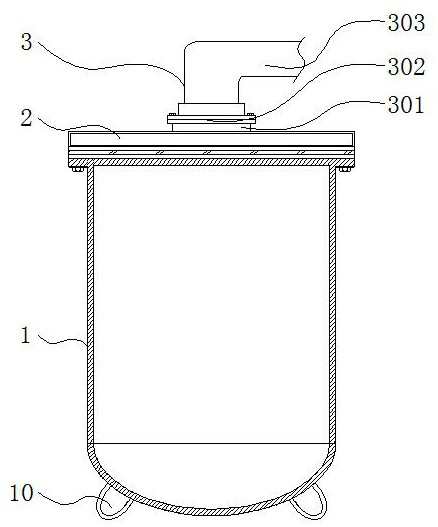

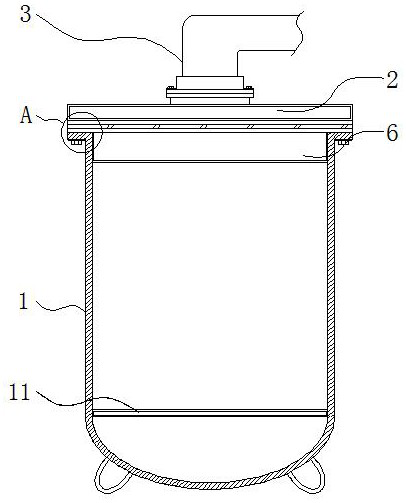

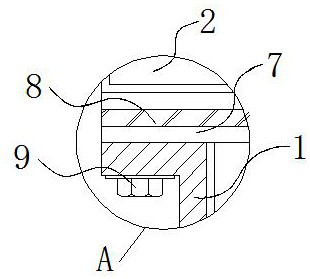

[0028] Such as Figure 1-5 As shown, the present invention provides a technical solution: a pollution-free and clean removal method after the production of sponge titanium, comprising a reactor pot 1, a reactor pot flange 7 and a head lifting lug 10, and the reactor pot 1 is equipped with The large cover 2 of the reaction kettle, and the upper and outer sides of the large cover 2 of the reaction kettle are provided with a feeding system 3, the finished products produced on the upper inner wall of the reaction kettle pot 1 have wall-climbing titanium 4, and the finished products produced under the inner part of the reaction kettle pot 1 There is a titanium lump 5, the bottom of the big cover 2 of the reactor is fixed with a large cover bottom 6, the flange of the reactor pot 7 is fixed on the outer ring of the upper side of the reactor pot 1, and the flange of the reactor pot 7 is connected with the reactor large A sealing rubber pad 8 is provided between the lids 2, fastening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com