Display equipment, modified ABS material and preparation method of modified ABS material

A technology of ABS material and display equipment, which is applied in the field of modified ABS material and its preparation, can solve the problems of hot front shell and other problems, achieve the effect of reducing surface temperature, realizing oil resistance and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

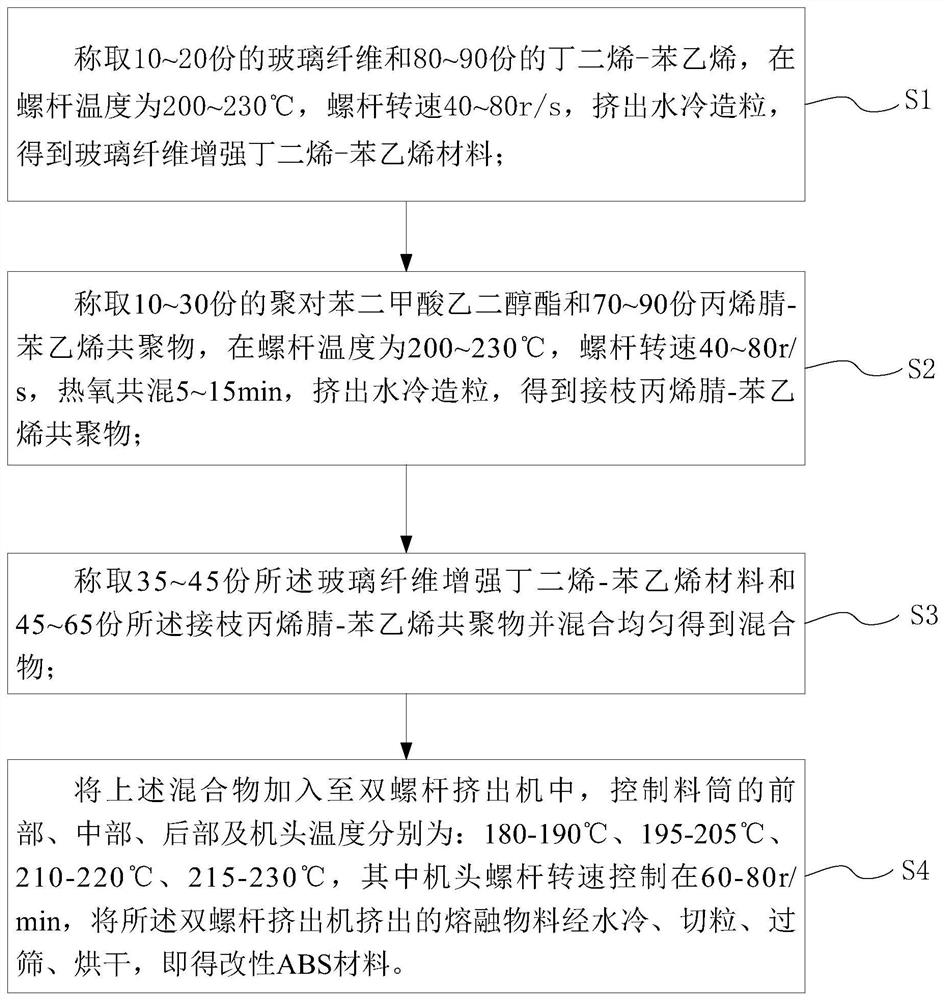

[0064] refer to figure 1 , figure 1 Show the flow chart of the preparation method of modified ABS material among the present application, this preparation method comprises the following steps:

[0065] S1. Weigh 10-20 parts of glass fiber and 80-90 parts of butadiene-styrene, extrude water-cooled granulation at a screw temperature of 200-230°C and a screw speed of 40-80r / s to obtain glass fiber Reinforced butadiene-styrene material.

[0066] S2. Weigh 10 to 30 parts of polyethylene terephthalate and 70 to 90 parts of acrylonitrile-styrene copolymer, and heat oxygen at a screw temperature of 200 to 230°C and a screw speed of 40 to 80r / s. Blending for 5-15 minutes, extruding and water-cooling to granulate to obtain grafted acrylonitrile-styrene copolymer.

[0067] S3. Weighing 35-45 parts of glass fiber reinforced butadiene-styrene material and 45-65 parts of grafted acrylonitrile-styrene copolymer and mixing them uniformly to obtain a mixture.

[0068] S4. Add the above mix...

Embodiment 1

[0071] In parts by weight, the modified ABS material includes 35 parts by weight of glass fiber reinforced butadiene-styrene material, 65 parts by weight of grafted acrylonitrile-styrene copolymer, 1 part of antioxidant and 1.5 parts of lubricant. Wherein, the glass fiber reinforced butadiene-styrene material includes 20 parts of glass fiber and 80 parts of butadiene-styrene. The length of the glass fiber is 4 μm, and the aspect ratio of the glass fiber is 4:1.

[0072] The grafted acrylonitrile-styrene copolymer comprises 10 parts of polyethylene terephthalate and 90 parts of acrylonitrile-styrene copolymer.

[0073] The preparation method of this modified ABS material comprises the following steps:

[0074] S11. Weigh 20 parts of glass fiber and 80 parts of butadiene-styrene, extrude at a screw temperature of 200°C and a screw speed of 80 r / s, and then water-cool and granulate to obtain glass fiber-reinforced butadiene-styrene material .

[0075] S12. Weighing 10 parts of...

Embodiment 2

[0079] In parts by weight, the modified ABS material includes 45 parts by weight of glass fiber reinforced butadiene-styrene material, 45 parts by weight of grafted acrylonitrile-styrene copolymer and 2.5 parts of antioxidant. Wherein, the glass fiber reinforced butadiene-styrene material includes 10 parts of glass fiber and 90 parts of butadiene-styrene. The length of the glass fiber is 7 μm, and the aspect ratio of the glass fiber is 3:1.

[0080] The grafted acrylonitrile-styrene copolymer includes 30 parts of polyethylene terephthalate and 70 parts of acrylonitrile-styrene copolymer.

[0081] The preparation method of this modified ABS material comprises the following steps:

[0082] S21. Weigh 10 parts of glass fiber and 90 parts of butadiene-styrene, extrude and water-cool granulate at a screw temperature of 230°C and a screw speed of 40r / s to obtain a glass fiber reinforced butadiene-styrene material .

[0083] S22. Weighing 30 parts of polyethylene terephthalate and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com