Method for preparing sintered brick from final aluminum ash

A technology of sintered bricks and aluminum ash, which is applied to clay products, applications, household appliances, etc., can solve problems such as aggravating environmental damage, limiting the large-scale utilization of sintered bricks, and increasing the complexity of brick-making processes, so as to simplify the preparation process, Realize the utilization of resources and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific examples, but it should not be construed as a limitation of the present invention. Without departing from the spirit and essence of the present invention, any modifications or substitutions made to the methods, steps or conditions of the present invention fall within the scope of the present invention. The experimental methods and unspecified formulations of the reagents in the examples that do not indicate the specific conditions are all in accordance with the conventional conditions in this field.

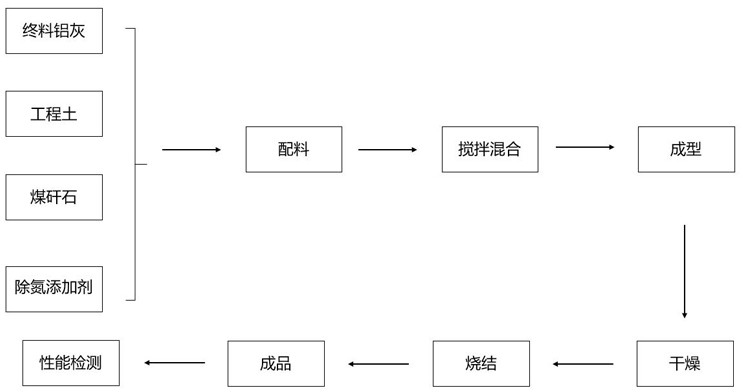

[0024] The invention provides a simple, environment-friendly and energy-saving sintered brick firing scheme. The main brick-making steps include batching, pressing, and sintering.

[0025] (1) Select aluminum ash final ash, engineering soil and coal gangue as the main raw materials for making bricks, wherein the aluminum ash final ash contains Al 2 o 3 , while Al 2 o 3 It is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com