A sampling anti-oxidation device for molten metal liquid

A molten metal, anti-oxidation technology, applied in the field of metallurgy, can solve the problems that molten metal is easily oxidized by air, affects the quality of metal, and oxidizes molten metal, and achieves the effects of avoiding large-area contact, strengthening heat preservation effect, and avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

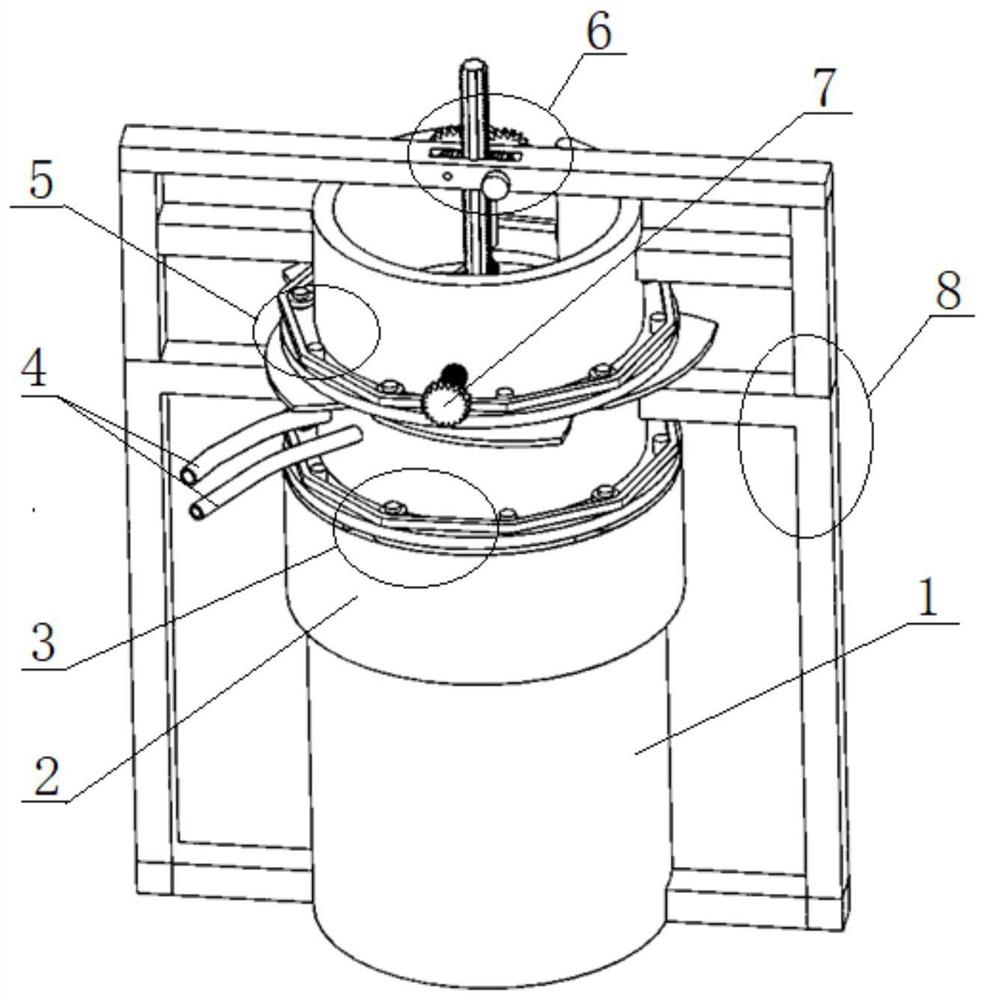

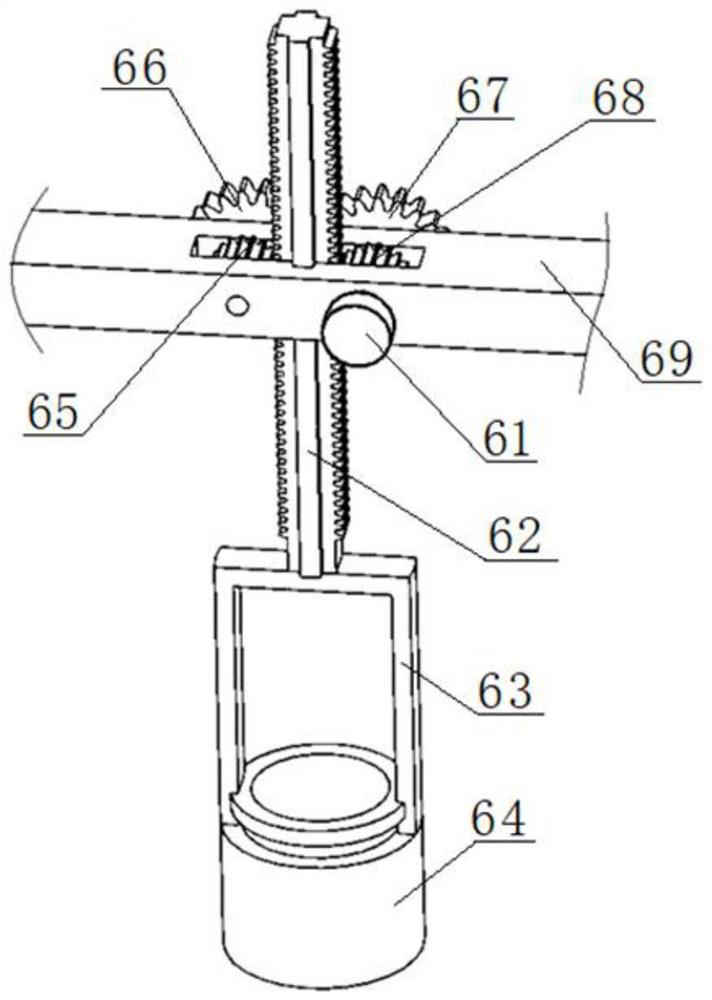

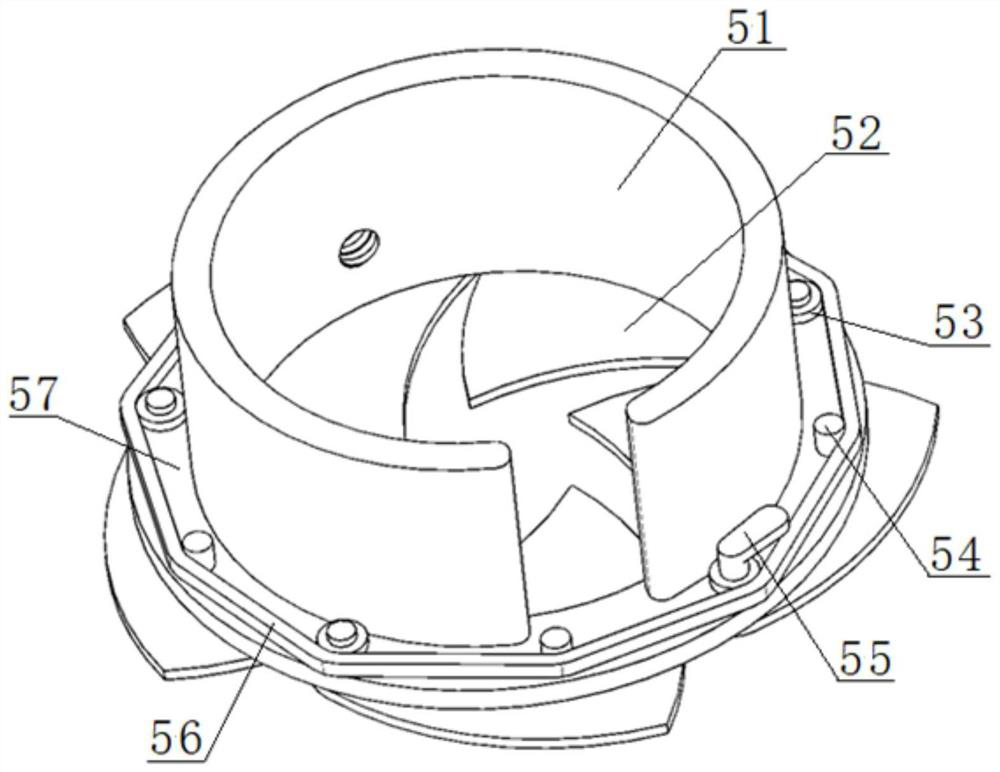

[0037] see figure 1 with Figure 9 , a sampling anti-oxidation device for molten metal, including a melting furnace, the top of the melting furnace is provided with an opening, the opening position is provided with a lower closing mechanism 3, and an upper closing mechanism 5 is arranged directly above the lower closing mechanism 3, and the lower closing mechanism Mechanism 3 and upper closing mechanism 5 are all arranged on the support 8, and the top of upper closing mechanism 5 is provided with elevating mechanism 6, and elevating mechanism 6 is connected with fetching barrel 64, and fetching barrel 64 can move in and out opening up and down.

[0038] A vertical cylinder 11 is provided at the top end of the melting furnace, and the upper end of the vertical cylinder 11 is the inlet and outlet of the solution.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com