Assembling method for sealing and silencing structure of compressor

An assembly method and compressor technology, which are applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of sharp increase in enterprise costs, high metal copper prices, and rising raw material prices, and achieve simple structure and manufacturing. And the effect of reducing the cost of use and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

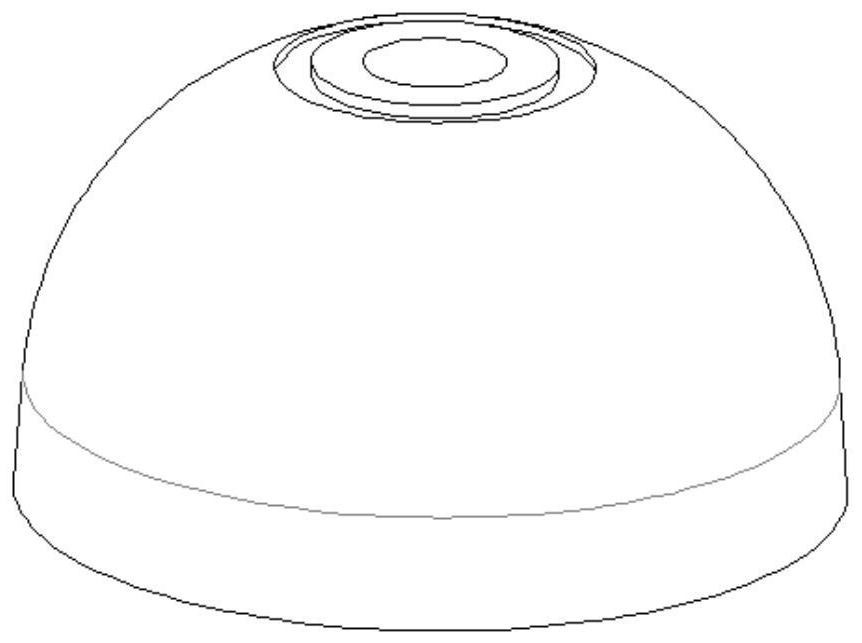

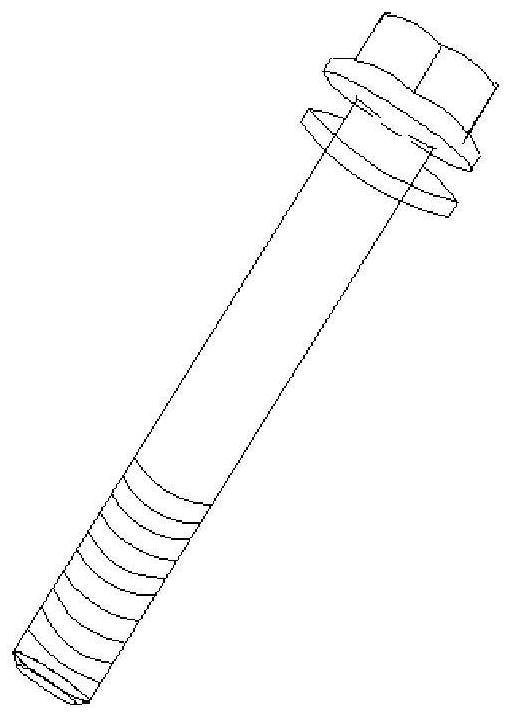

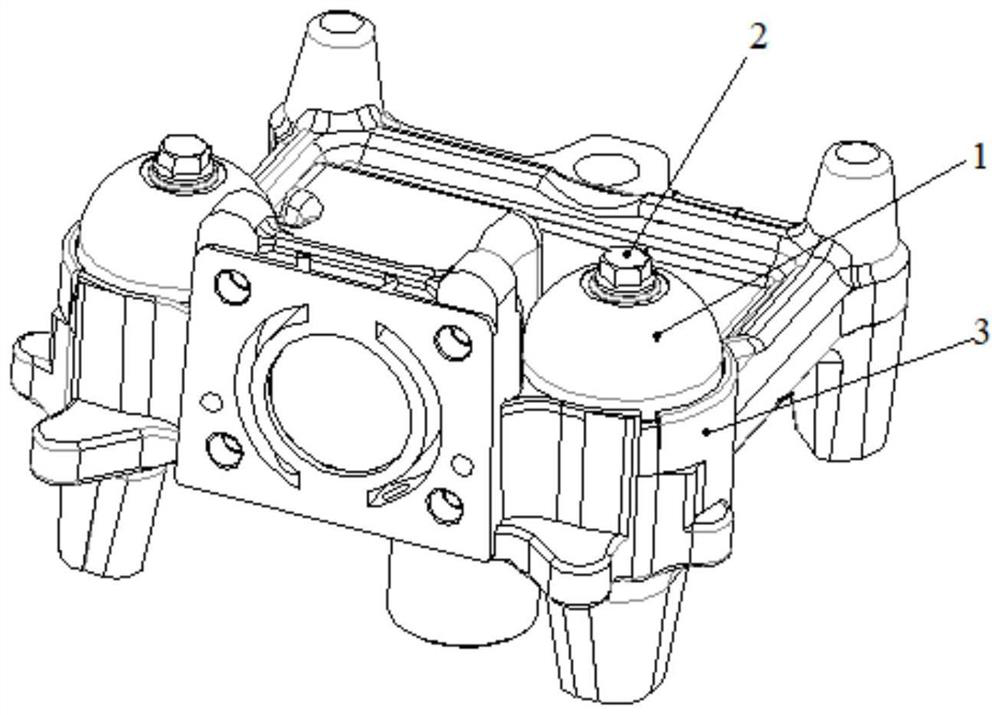

[0045] Embodiment one, such as Figure 4 Shown:

[0046] The present invention improves the sound-absorbing cover, cancels the copper washer screw and improves the cylinder block, that is: the compressor sealing and sound-absorbing structure of the present invention, the outer end of the through hole of the fastening screw 2 is installed on the described sound-absorbing cover 1, and the sealing boss 1.2 is set.

[0047] The invention overcomes the disadvantages of the prior art, and adopts the method of canceling the copper washer and improving the sound-absorbing cover, the screw and the cylinder seat to realize the purpose of reducing the cost and realize the requirement of effective sealing. The cost of the existing sound-absorbing fastening structure is reduced, and the technical index required by the compressor fastening process is met.

[0048] In order to achieve a close fit between the boss sealing surface and the lower plane of the nut of the fastening screw 2, and t...

Embodiment 2

[0069] In order to further improve the sealing effect of the sound-absorbing structure, on the basis of the first embodiment above, a high-temperature-resistant sealant is provided between the annular sealing surface of the sealing boss 1.2 and the screw pressing surface 2.3 of the fastening screw 2. Layer 5.

[0070] The high-temperature-resistant sealant is polymerized by high-performance heat-resistant resin and various heat-resistant materials. Good quality and other characteristics. Generally, a sealant resistant to 350°C is used, which is made of basic resin, high-purity filler, electronic-grade reactive diluent, advanced additives, and processing aids, which are made by mechanical mixing and vacuum treatment.

[0071] In order to achieve the purpose of the invention of the sealing structure of the exhaust high-pressure chamber of the compressor described in Embodiment 2, the present invention also provides an assembly method of the sealing and noise-absorbing structure...

Embodiment 3

[0077] Embodiment three, such as Figure 7 Shown:

[0078] In order to further improve the sealing performance of the compressor sound-absorbing sealing structure, simplify the structure, and reduce production costs, the present invention also provides another bolt-free compressor sealing and sound-absorbing structure, and its technical solution is:

[0079] The compressor includes a cylinder block 3 and a sound-absorbing cover 1, and the sound-absorbing cover 1 is pressed into the seam of the cylinder block 3 to form a tight fit; Coating of high temperature sealants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com