Underground goaf processing method combining filling and artificial supporting columns

A processing method and combined technology, applied in fillings, pillars/supports, earthwork drilling, etc., can solve problems such as difficulty in constructing artificial pillars, and achieve the effect of safe surface and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

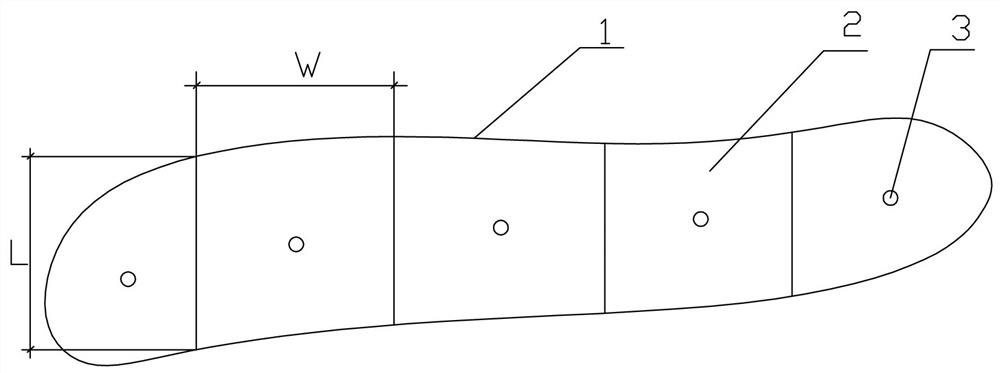

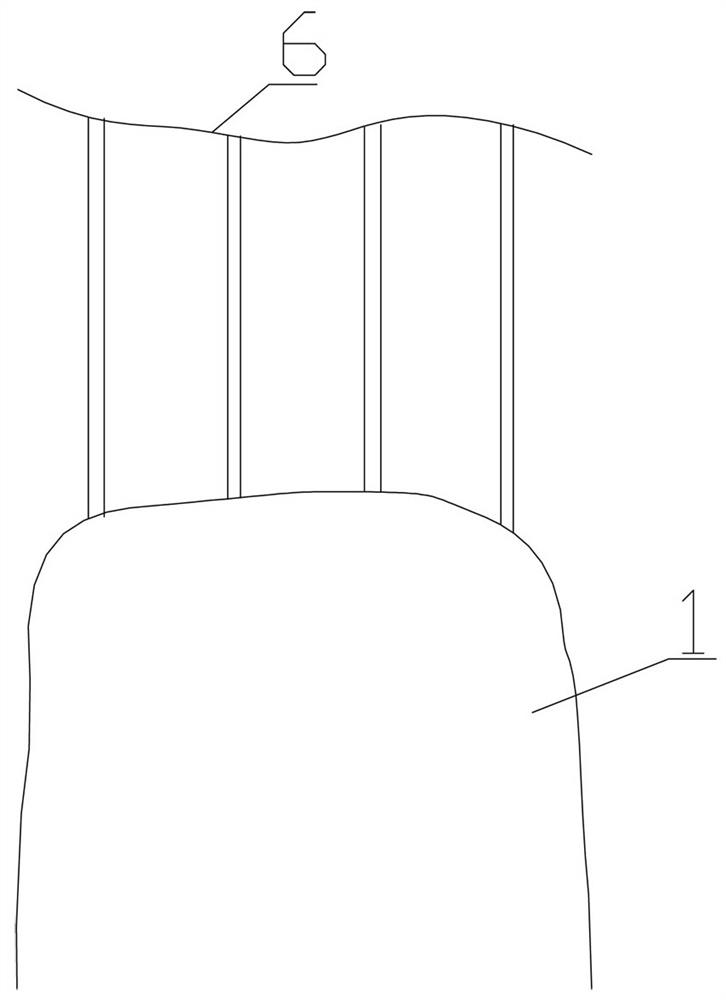

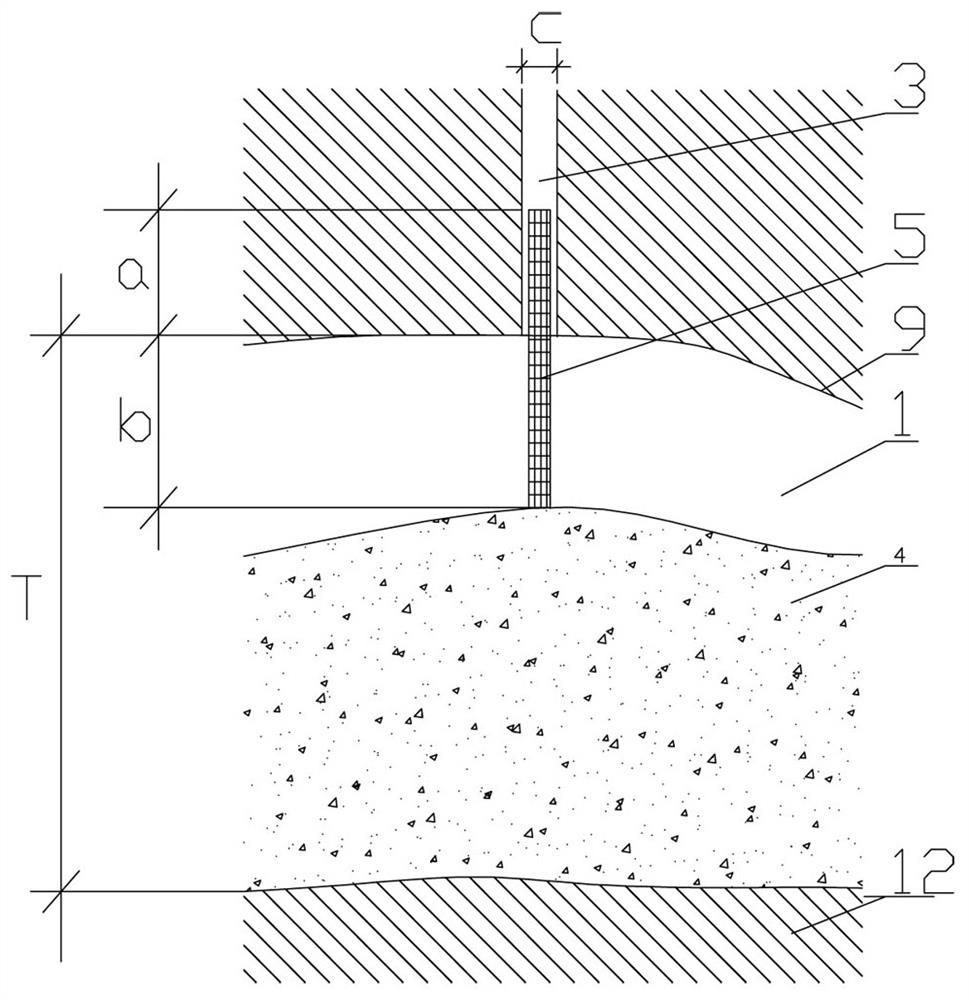

[0026] Such as Figure 1-Figure 4 As shown, a method for treating underground voids combined with filling and artificial pillars according to the present invention is characterized in that the roof of the underground voids is divided into several areas 2 along the direction, and a filling well is arranged at the center of each area 2 3. The filling well 3 is directly connected to the underground space 1 from the surface 6, and the gravel and dressing tailings are filled into the underground space 1 through the filling well 3 on the surface 6 as the lower filling body 4 of the underground space 1, such as image 3 As shown, the distance between the surface of the filling body 4 in the lower layer and the bottom of the filling well 3 is b = λ 1 T / (λ 1 -λ 2 +1), lower the reinforcement cage 5 from the filling well 3, so that the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com