Self-resetting viscous damper based on combined spring

A technology of viscous damper and combined spring, which is applied to building components, shockproof, building types, etc., can solve the problems of limited energy dissipation capacity of self-resetting viscous dampers and the inability of the balance plate to return to the initial equilibrium position completely. The effect of excellent self-reset capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below through specific embodiments and accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

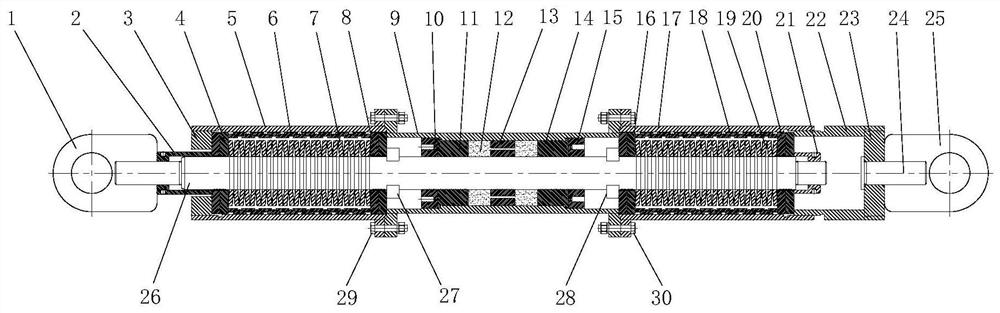

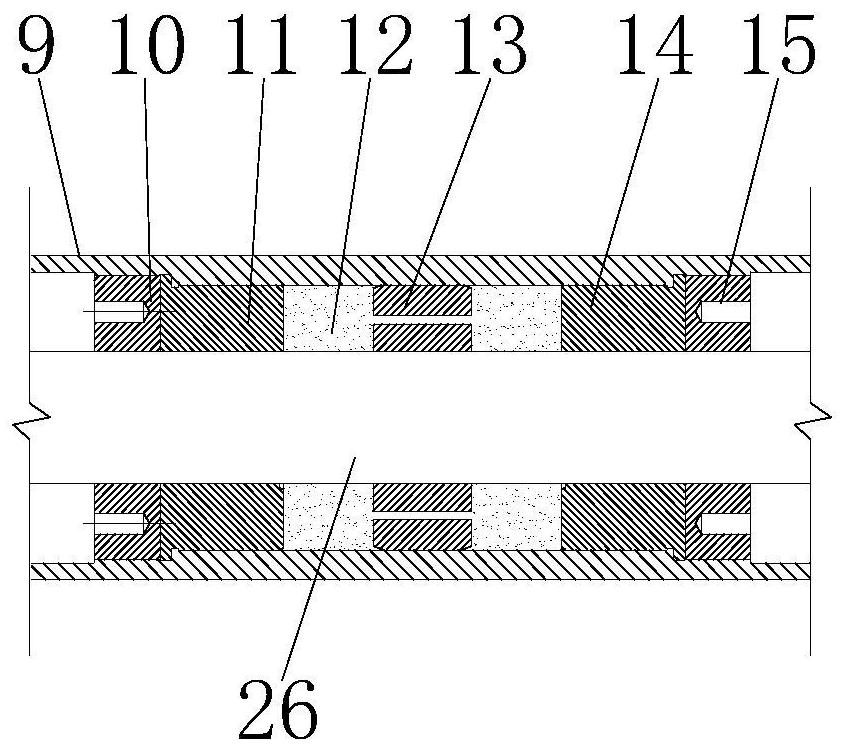

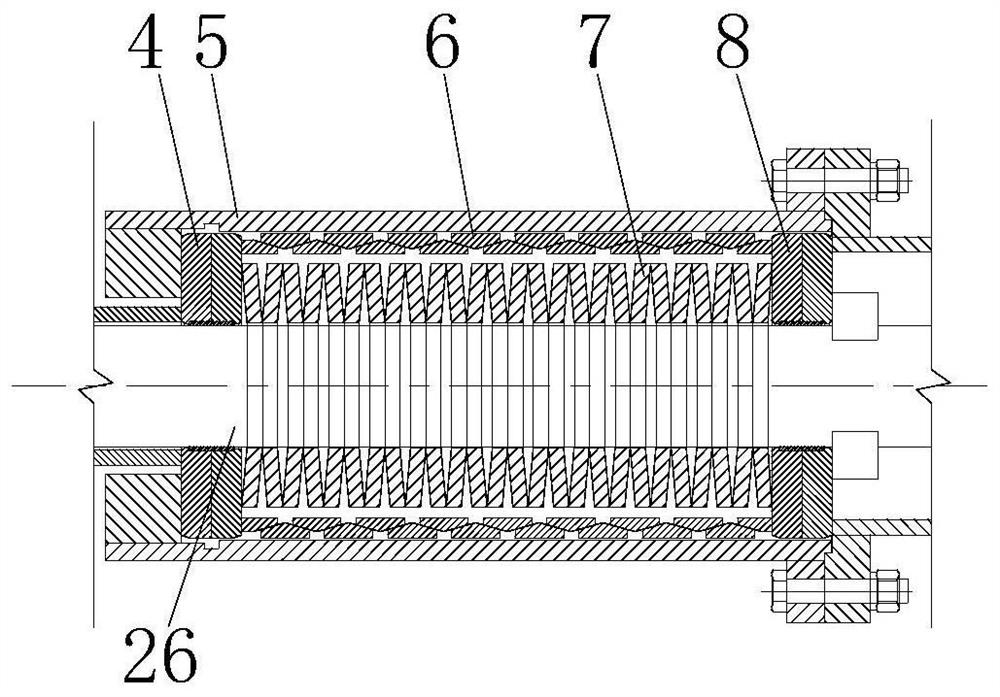

[0066] Such as Figures 1 to 16 As shown, a self-resetting viscous damper based on a combined spring includes a viscous damping energy-dissipating device, a spring return device and a force transmission device. The force transmission device makes the viscous damping energy-dissipating device and the spring return device work together. The viscous damping energy dissipation device is located in the middle of the self-resetting viscous damper, consisting of the piston 13, the first guide sleeve 11, the second guide sleeve 14, the first damping end cover 10, the second damping end cover 15 and the viscous damping fluid 12 components, the viscous damping fluid 12 is silicone oil. The spring return device includes two spring return devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com