High vertical grid type offshore wind power foundation anti-scouring system and method

An offshore wind power and grid technology, applied in wind power generation, infrastructure engineering, wind turbines, etc., can solve the problems of general protection effect and high construction cost, and achieve the effect of strengthening strength, avoiding collapse and increasing stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

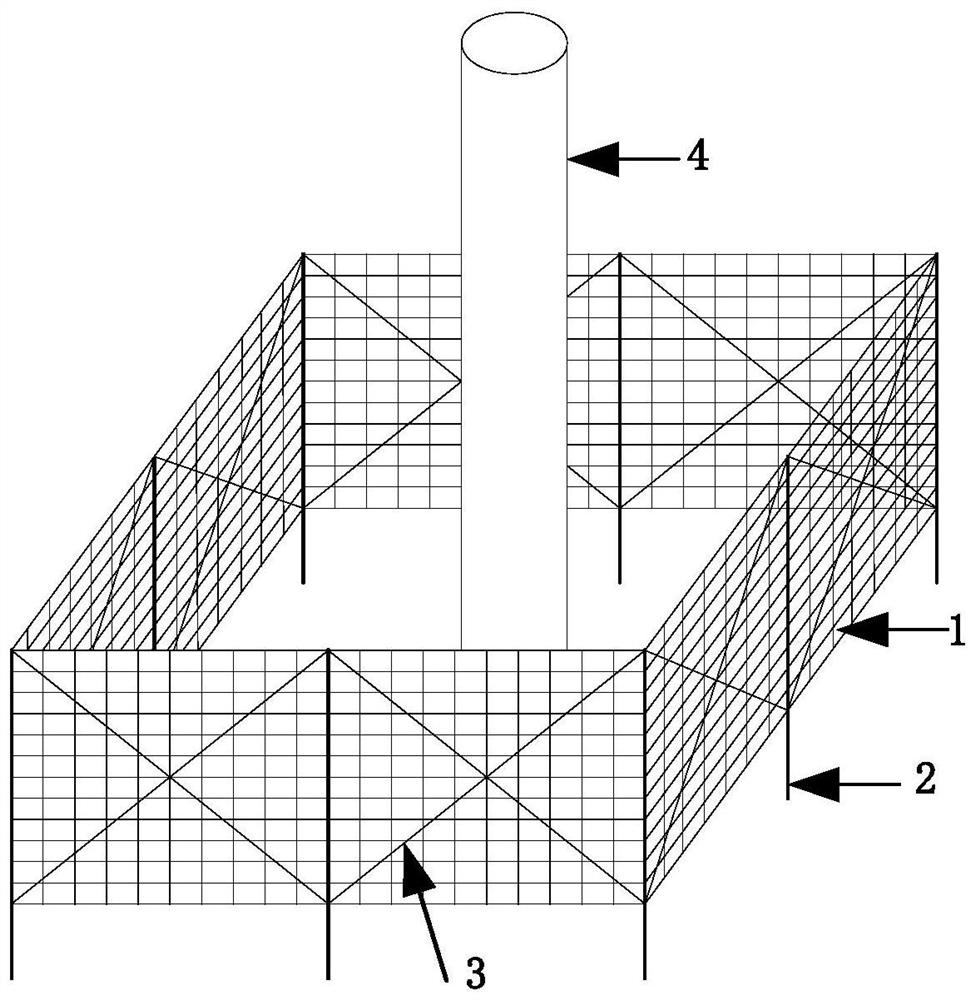

[0031] see figure 1 As shown, the present invention provides an anti-scouring system for offshore wind power foundations in a high vertical grid format, including grids 1, columns 2, reinforced connecting ribs 3 and offshore wind power foundations 4;

[0032] Several grids 1 are arranged around the offshore wind power foundation 4 , each grid 1 is vertically fixed by two uprights 2 , and each grid 1 is provided with two reinforcing connecting ribs 3 on its diagonal.

[0033] The grid 1 is in the shape of a rectangular net, made of corrosion-resistant metal material or high-strength fiber material, and its porosity is 10% to 50%.

[0034] The bottom edge of the grid 1 is close to the seabed surface.

[0035] Column 2 is a corrosion-resistant metal cylinder, buried in the seabed and fixed.

[0036] Reinforced connecting ribs 3 are corrosion-resistant metal connectors.

[0037] A plurality of grids are connected end to end and form a grid structure around the offshore wind pow...

Embodiment 2

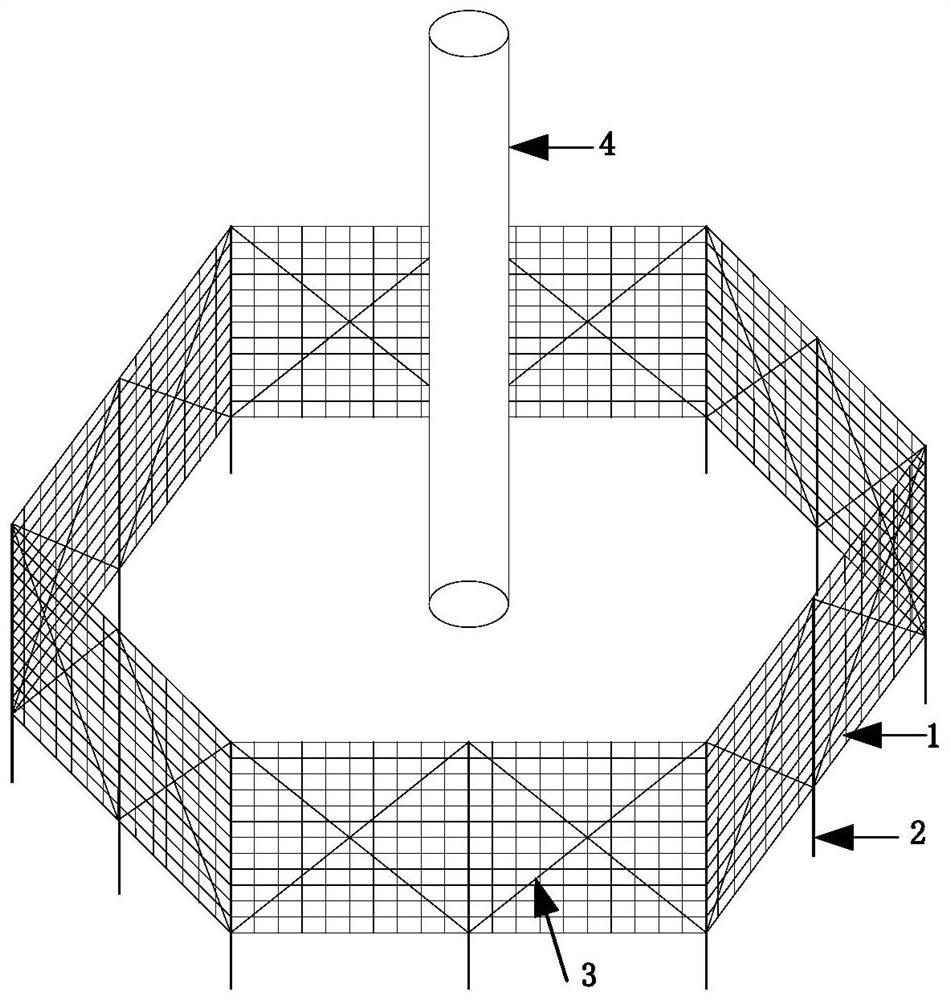

[0041] see figure 2 As shown, the second embodiment has the same structure as the first embodiment, but the shape of the grid cross section is different, and the shape of the grid cross section in this embodiment is a regular hexagon. The reason for this embodiment is that the protection range of a regular hexagon is greater than that of a square.

Embodiment 3

[0043] On the basis of Embodiment 1 or 2, according to the actual needs of the project, a multi-layer grid structure can be arranged around the offshore wind power foundation 4 to enhance the protection effect. The cross-sections of the multi-layer grid structure are the same or different. When they are different, the flow direction of seawater and sediment passing through different layers of grids 1 can be changed, the flow velocity of sediment can be further reduced, and the anti-scouring effect can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com