Double-liquid quenching process and quenching device

A technology of double-liquid quenching and quenching device is applied in the field of quenching, which can solve the problems of reducing the effect and error of the first quenching, and achieve the effects of uniform speed, improving efficiency and effect, and reducing evaporation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

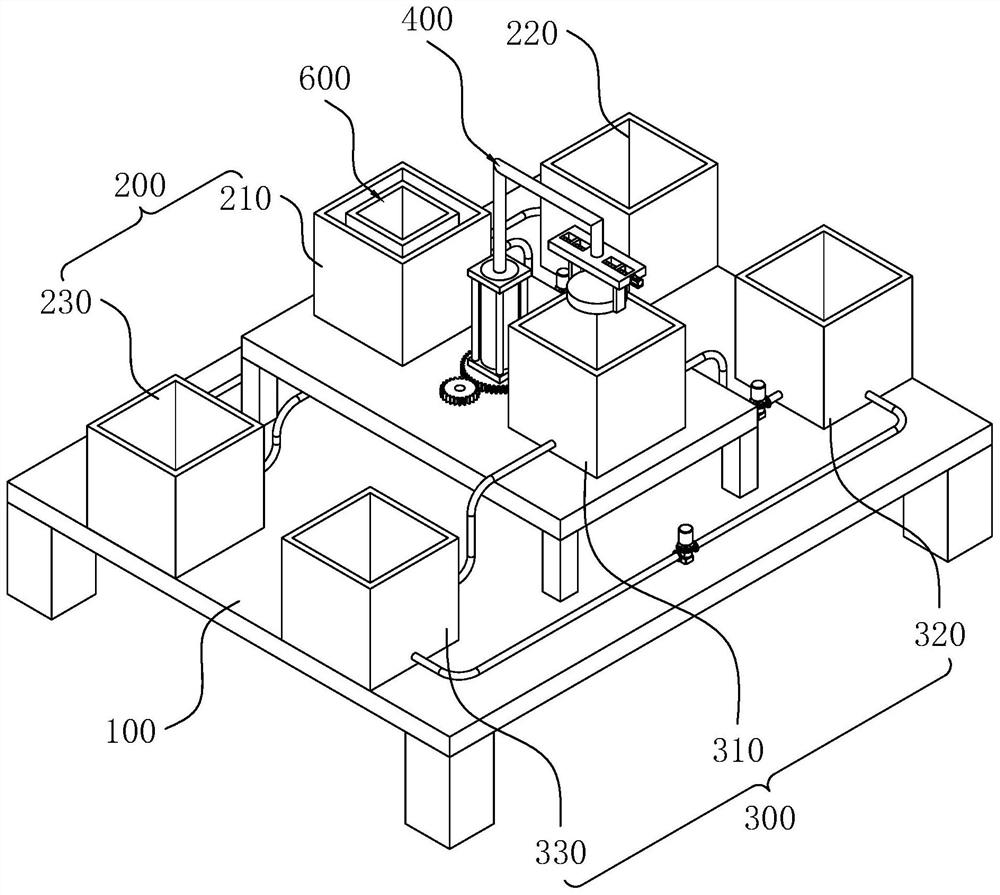

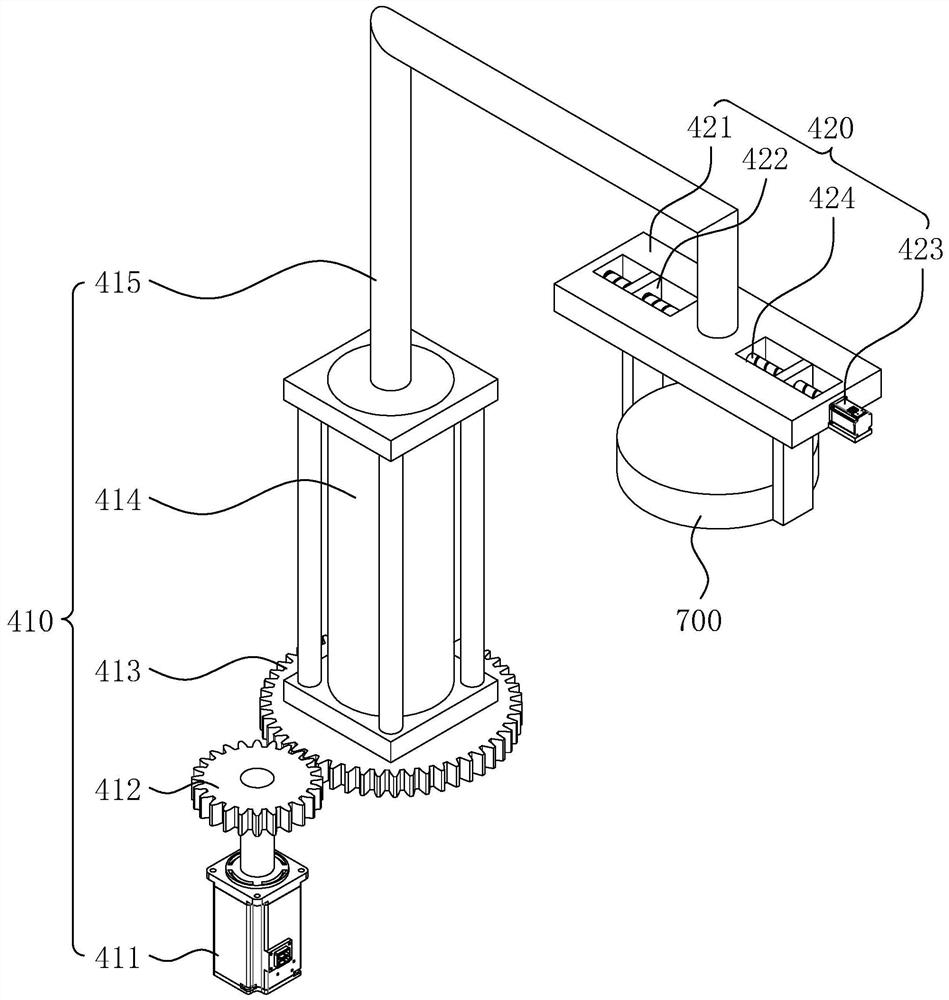

[0042] The following is attached Figure 1-4 The application is described in further detail.

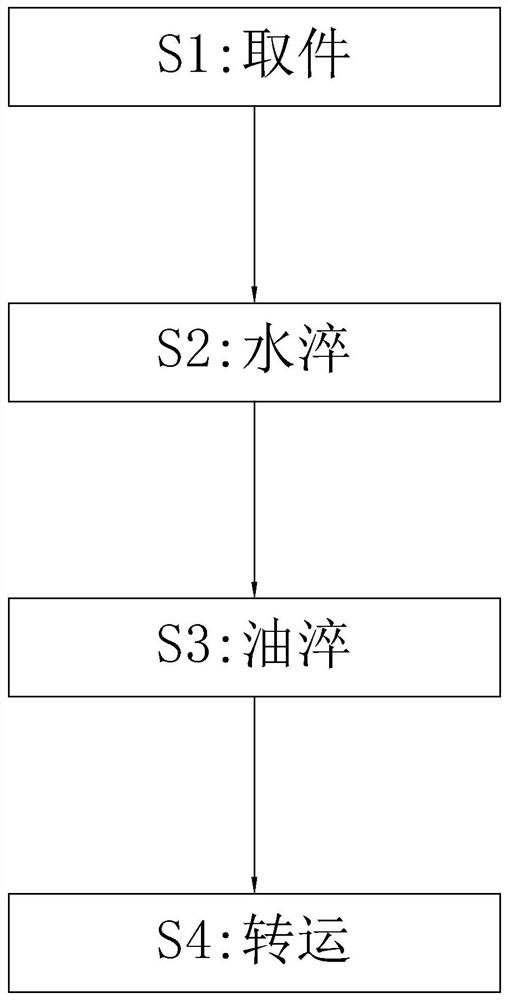

[0043] The embodiment of the present application discloses a two-liquid quenching process and a quenching device. First of all, the embodiment of the present application discloses a two-liquid quenching process, referring to figure 1 , a two-liquid quenching process comprises the following steps:

[0044] S1: Pick up, use the clamping mechanism to take the heated workpiece out of the heating furnace;

[0045] S2: Water quenching, using water as a rapid coolant, put the heated workpiece into the water through the clamping mechanism, and quench the workpiece for the first time; during the first quenching process, the cooling water flows from around the workpiece to the workpiece The axis flows; the workpiece is cooled to 300°C for the first quenching, and the temperature of the workpiece is directly measured by a thermocouple during the first quenching;

[0046] S3: Oil quenching, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com