Automatic welding device for argon tungsten-arc welding of deep hole in inner wall of pipe fitting

A technology of argon tungsten arc welding and automatic welding, which is applied in welding equipment, welding accessories, arc welding equipment, etc., and can solve the problems of difficult observation of deep hole welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be apparent from the embodiments of the present invention, which will be described below, as will be described herein, not all of the embodiments of the invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

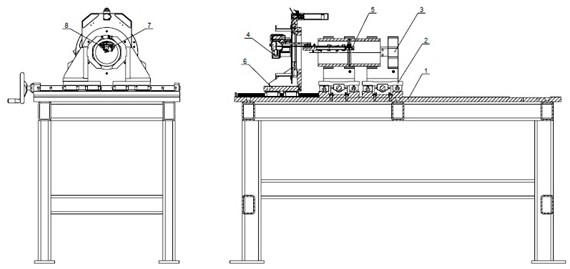

[0018] See figure 1 Embodiments of the present invention include:

[0019] A deep hole welding dedicated positioning group is composed of a tooling device, including a table 1, a clamping mechanism 2, and a workpiece positioning V block 3. Wear welder is hoisted to the workbench 1, placed on the workpiece positioning V block and use the clamping mechanism 2 to keep the workpiece lock to hold the workpiece.

[0020] A deep hole welding automatic pair of welding devices, including full positional welding head 4, deep hole torch 5, head br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com