Feeding mechanism and double-end chamfering equipment

A feeding and chamfering technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems of automatic feeding of pipes, etc., and achieve the effect of ingenious structural design, high degree of automation, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

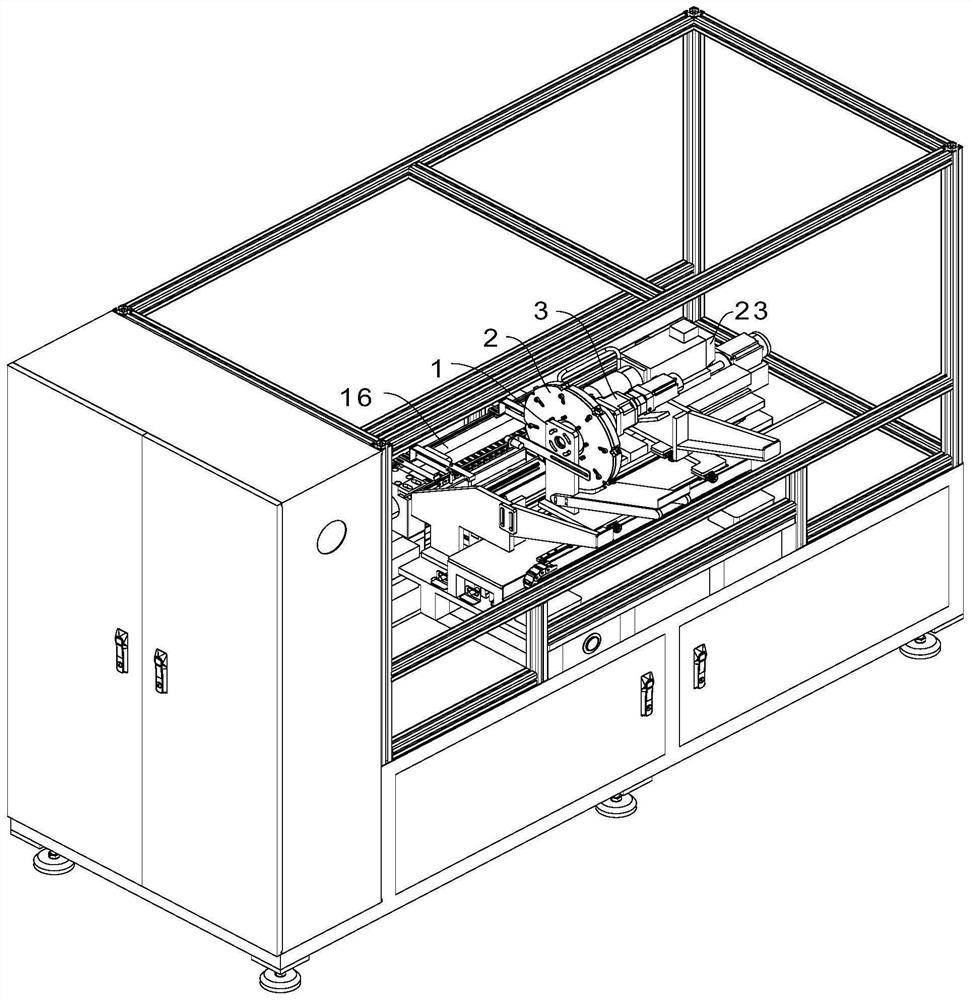

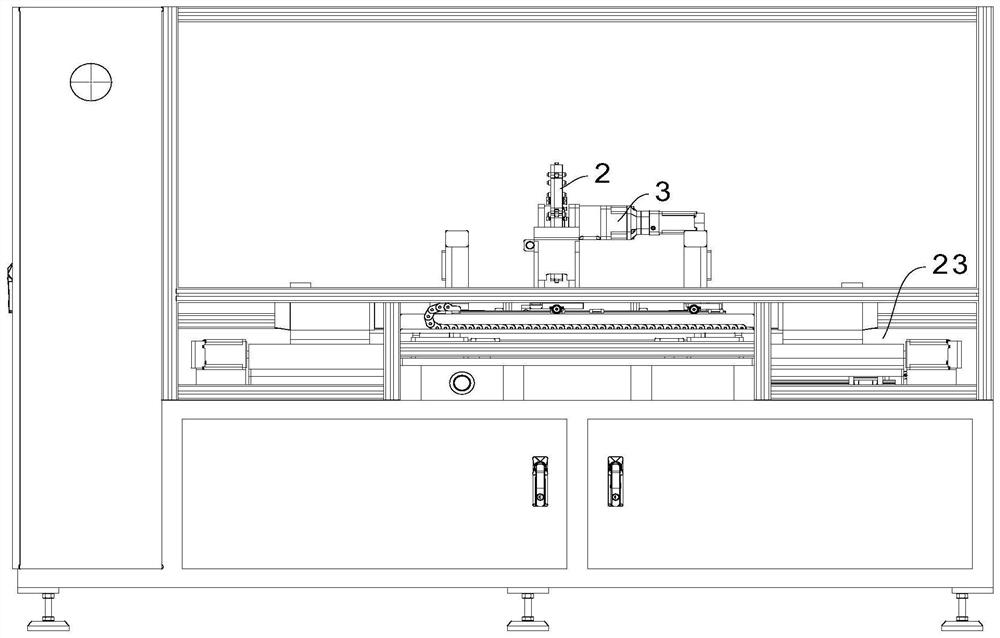

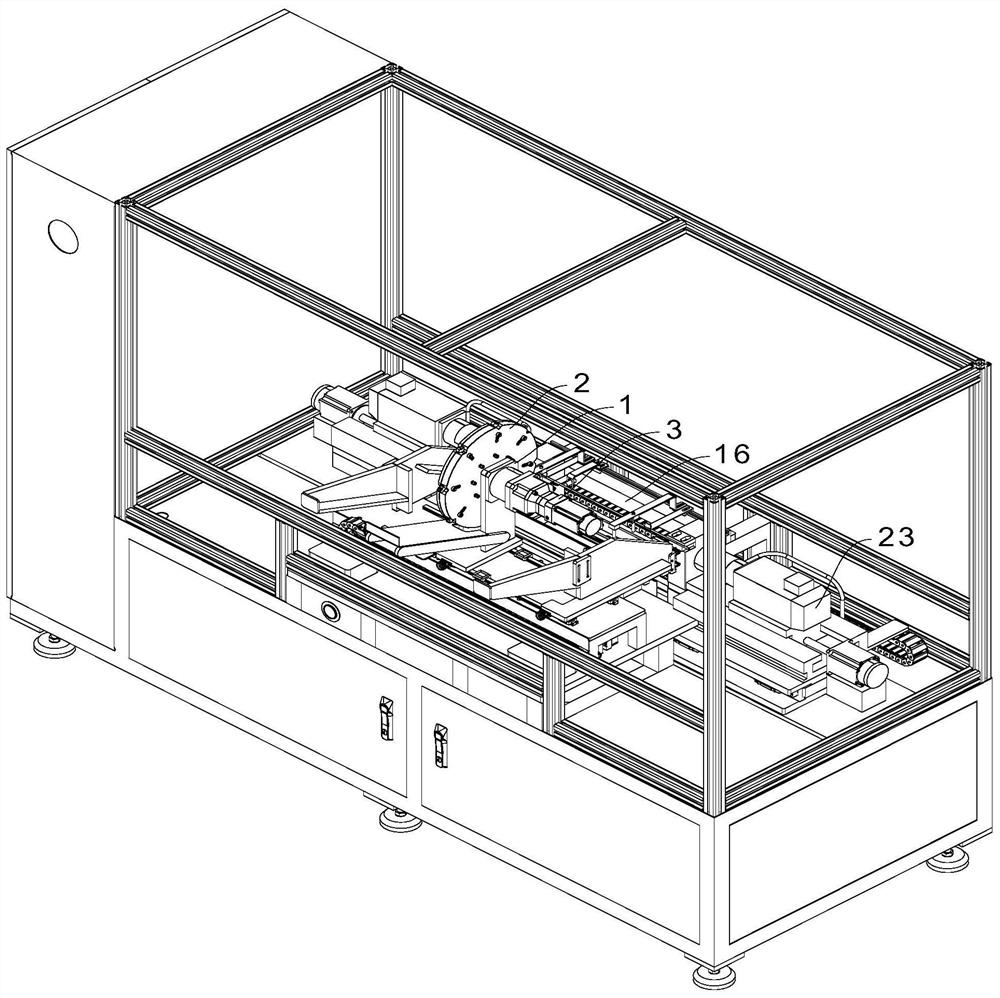

[0047] A double-head chamfering equipment, such as Figure 1 to Figure 11 As shown, a feeding mechanism is included, and the feeding mechanism includes a bracket 1, a feeding tray 2 rotated on the bracket 1, a rotary drive device 3 that drives the rotation of the loading tray 2, and the bracket 1 is formed with Feeding station 4, the feeding tray 2 is equipped with a plurality of hooks 5 and a plurality of tension springs 6, the hooks 5 can move in the radial direction of the feeding tray 2, and the tensioning The elastic force of the spring 6 acts on the hook body 5 and drives the hook body 5 close to the middle part of the feeding tray 2, and the hook body 5 is close to the outer edge 8 of the feeding tray (referring to the peripheral side wall of the feeding tray 2) One end of one end is formed with a hook 7, and a clamping gap is formed between the hook 7 and the outer edge 8 of the feeding tray. The bracket 1 is provided with a convex portion 9, and the convex portion 9 i...

Embodiment 2

[0060] A kind of double-head chamfering equipment, the difference from Embodiment 1 is that the reference Figure 12 , the feeding tray 2 is integrally formed, the side wall is formed with a concave cavity 26, the convex part 9 is installed and fixed on the fixed shaft 1b and is located in the concave cavity 26, the chute 11 and the The concave cavities 26 are connected, and the end of the hook body 5 close to the middle of the feeding tray 2 enters the concave cavity 26 , the structure is simpler, and the feeding function can also be realized at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com