Modularized magnetic flux reversing motor

A magnetic flux reversal and modularization technology, applied in the direction of magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of reducing the amount of permanent magnets, high vibration and noise of the motor, and large torque ripple of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

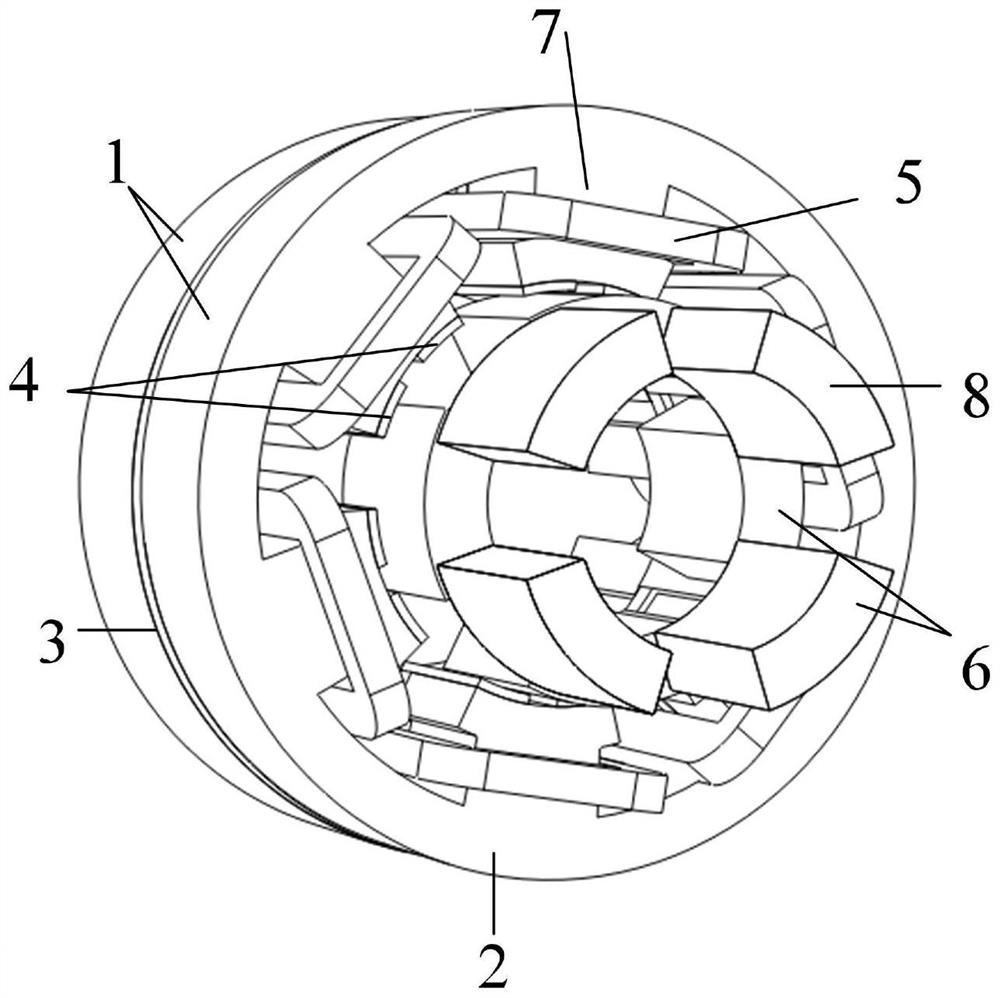

[0041] This embodiment adopts a 6-slot / 4-pole magnetic flux reversal motor with an inner rotor structure, and there are two modular units 1, such as figure 1 As shown, the effective length of the overall motor is 75mm.

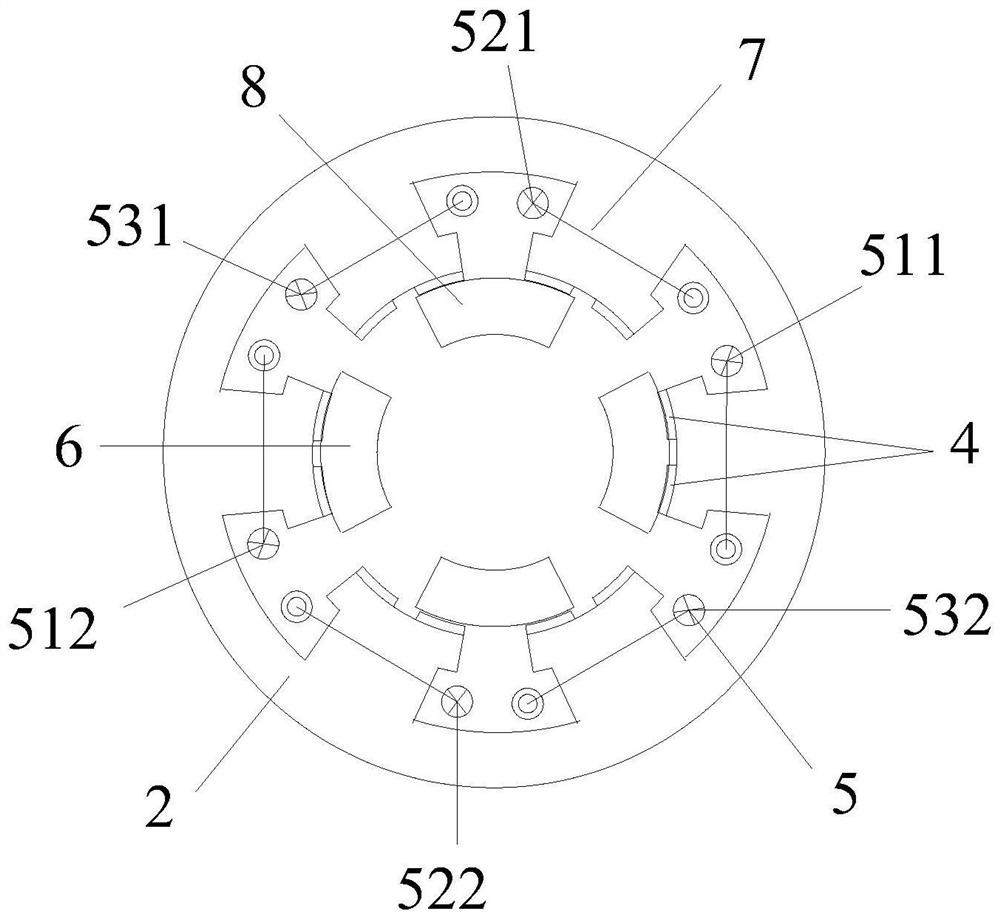

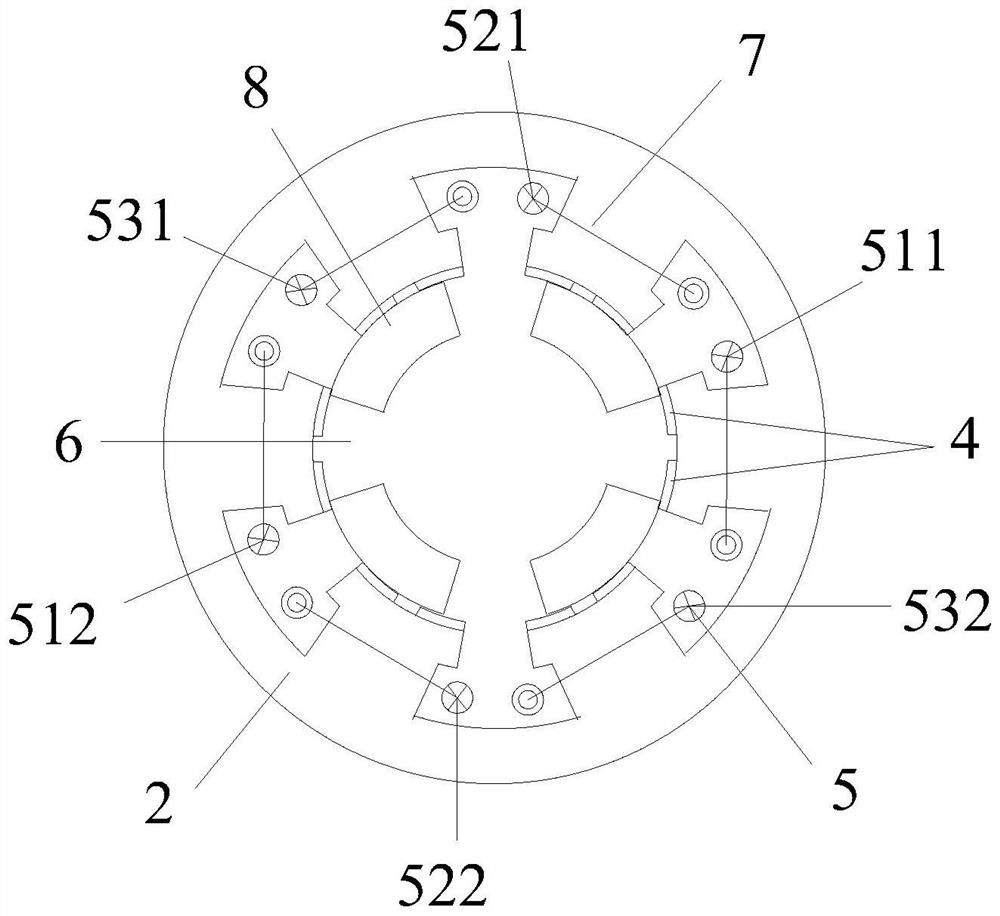

[0042] In each modular unit 1, there are 6 stator teeth 7, which adopt a salient pole structure and are evenly distributed in the circumferential direction of the stator core 2. The stator pole arc is 40.5°, the inner diameter of the stator core 2 is 70.4 mm, and the outer diameter of the stator core 2 is 128mm. The thickness of the permanent magnet magnetization direction is 1.6mm, and the pole arc of the permanent magnet is 18deg.

[0043] In each modular unit 1, the armature winding 5 has 6 centralized ring windings, which are respectively A-phase positive pole armature winding 511, A-phase negative pole armature winding 512, B-phase positive pole armature winding 521, and B-phase negative pole winding. Armature winding 522, C-phase positive pole armature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com