Tool for preparing composite material test sample piece and preparation method of test sample piece

A technology of composite materials and composite material boards, applied in the field of non-metallic material manufacturing, can solve problems such as poor sample consistency, test failure, and debonding of reinforcement sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

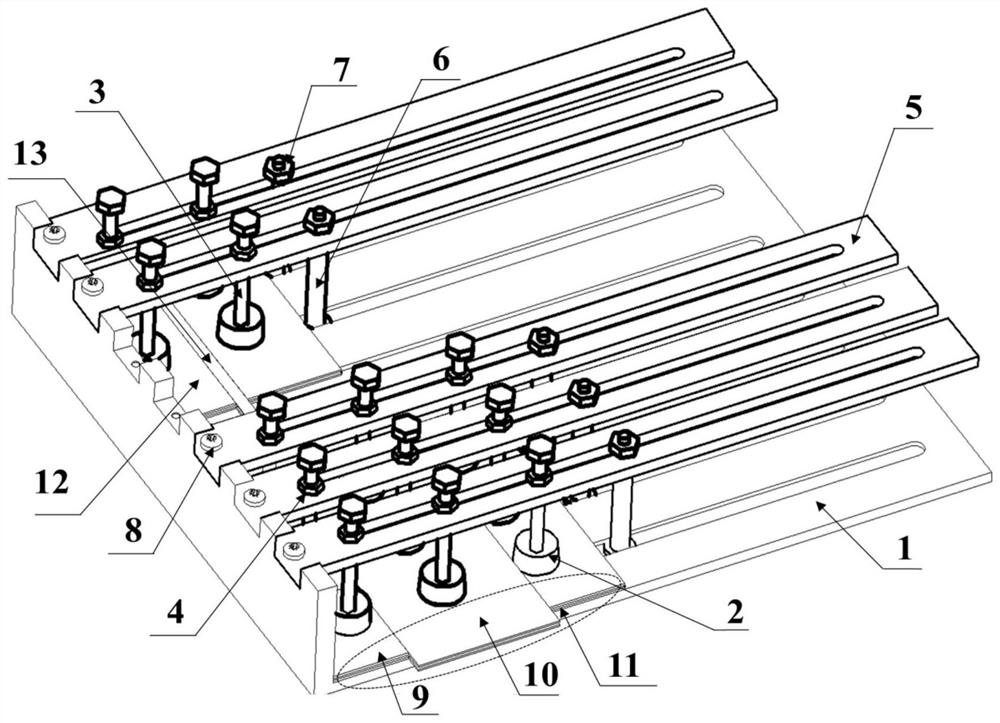

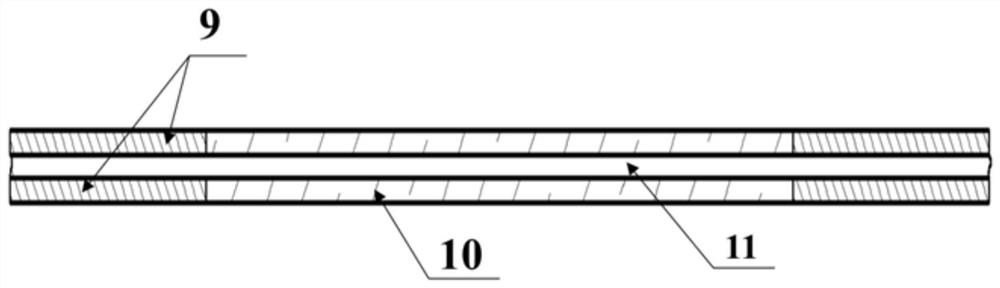

[0035] The present invention will be further described in conjunction with examples and accompanying drawings. The example is the preparation of a tensile sample of a carbon fiber composite material plate (11), and this example is only a part of the present invention.

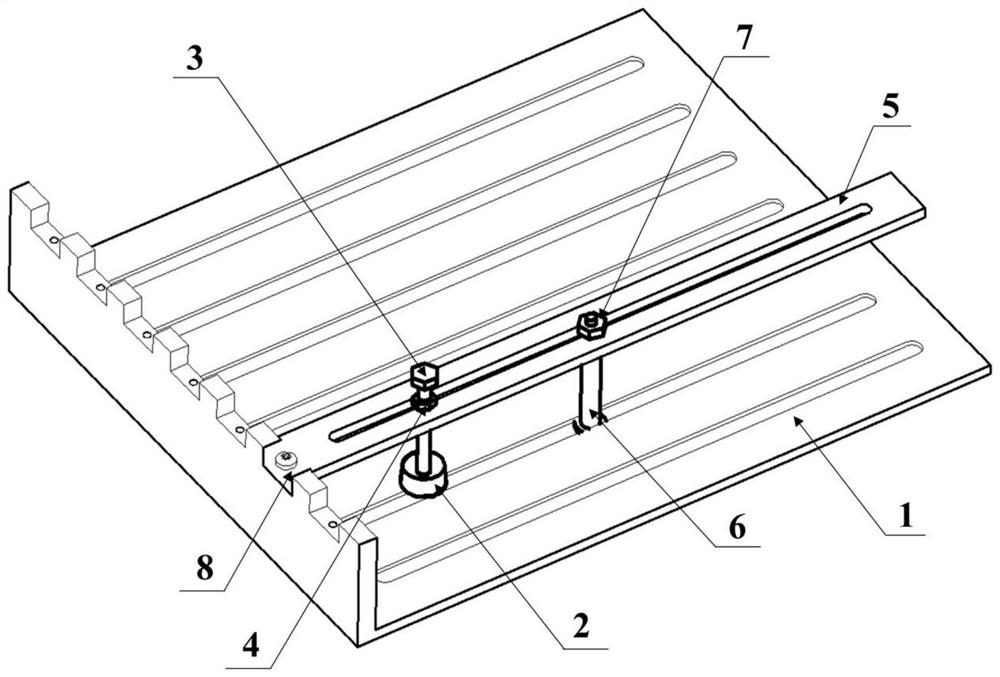

[0036] The invention proposes a tooling and processing method for assisting the preparation of composite material test samples. The special tooling is used to fix the sample blank of the three-layer composite structure composed of a reinforcement plate, a limit plate and a composite material plate to be tested, and assist in the preparation of the sample blank. Composite material mechanical performance test sample with reinforcement sheet, which is characterized in that the limit plate, reinforcement plate and composite material board to be tested are fixed on the special tooling first, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com