Electric supporting rod electromagnetic brake

A technology of electromagnetic brake and transmission gear, which is applied in the direction of brake type, mechanical brake, and brake parts, etc. It can solve the problems of car door falling, abnormal opening and closing, and user injury, etc., and achieves rapid brake adjustment, small size, and space occupation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The electric strut electromagnetic brake is mainly divided into a power-on type electromagnetic brake and a power-off type electromagnetic brake. The whole electromagnetic brake is an integral type, with small dimensions and small space occupation, which can meet the assembly requirements of different occasions.

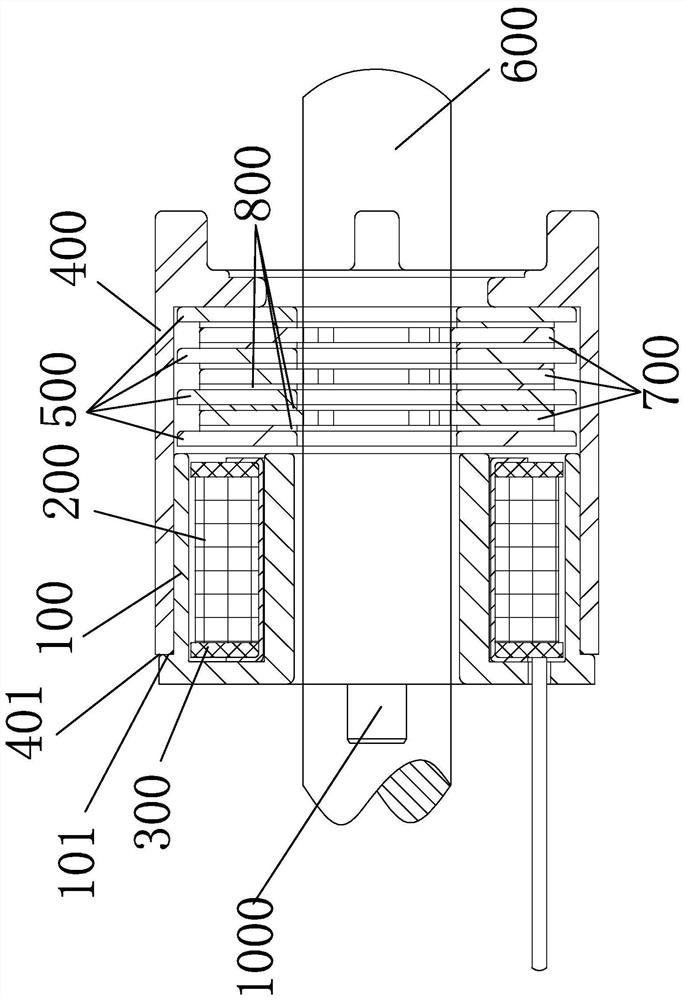

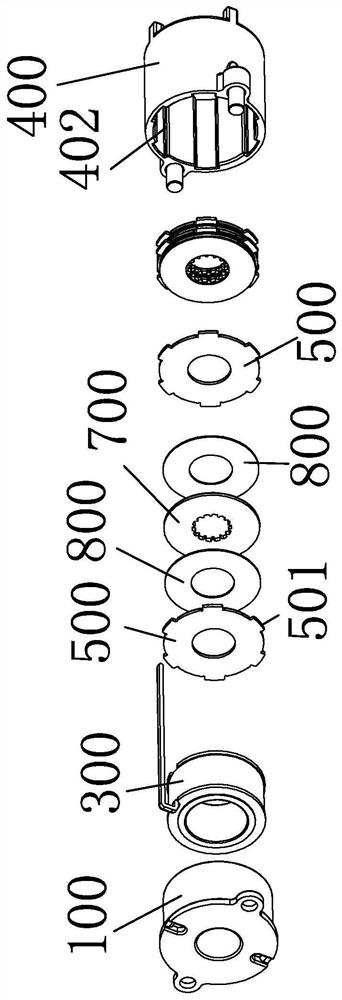

[0022] like figure 1 and figure 2 As shown, it is an energized electromagnetic brake, including a stator 100, a coil 200, a coil frame 300, a housing 400, an armature pressing piece 500, a friction assembly and a spline shaft 600, and the coil 200 is wound on the coil frame 300 to form a coil assembly assembly And assembled to the inside of the stator 100, in order to ensure the reliability of the winding and installation of the coil 200, as an optimization, the coil frame 300 has an interference fit with the inner boss of the stator 100 through its inner hole or the boss at the end of the coil frame 300 and the One end of the stator 100 is fitted with a hol...

Embodiment 2

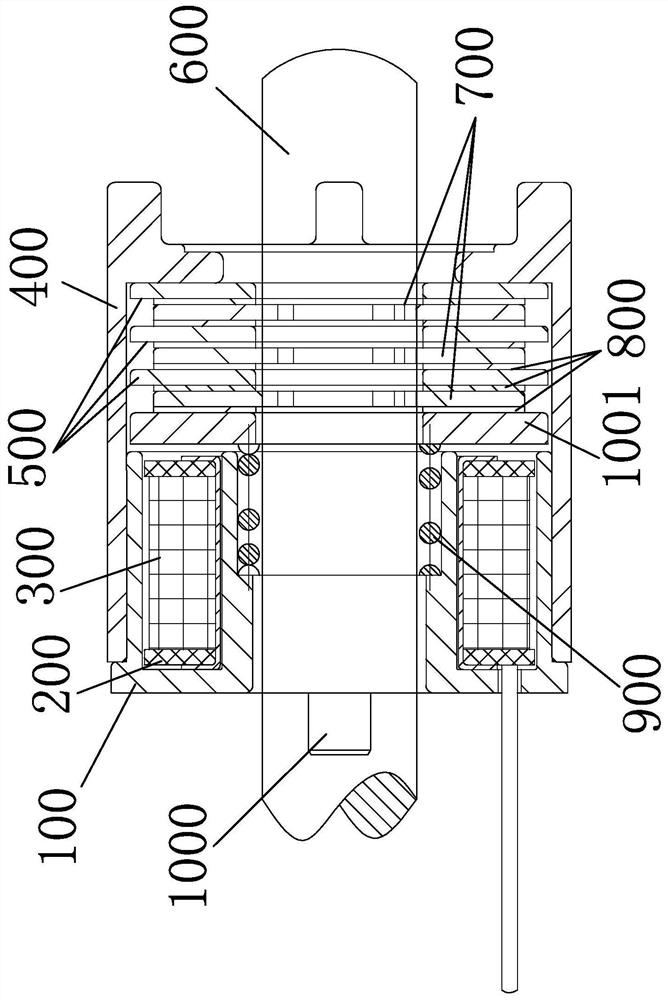

[0025] This embodiment is a power-off type electromagnetic brake, and most of the structure of this embodiment is the same as that of Embodiment 1, such as image 3 As shown, the difference is that the electric strut electromagnetic brake also includes a spring 900, wherein one of the armature pressing pieces 500 next to the coil 200 is changed to a larger armature 1001, and one end of the large armature 1001 is connected to the spring 900, The other end of the spring 900 is placed inside the hole of the stator 100. In addition, the large armature 1001 is also provided with a pawl anti-rotation structure 501, and a slot 402 matching the pawl anti-rotation structure 501 is provided in the housing 400. Here, the coil 200 In the power-off state, due to the existence of the spring 900, the spring 900 generates pressure on the large armature 1001 by itself and transmits it to the transmission ring gear 700 and the friction plate 800. When the spline shaft 600 rotates, it drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com