Preparation method and application of a nickel phosphide-ruthenium phosphide/nickel foam three-dimensional self-supporting electrode material

A self-supporting electrode, nickel foam technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve problems such as increasing the cost of hydrogen production, restricting the large-scale application of hydrogen production technology from electrolyzed water, etc. performance, and the effect of enhancing electrocatalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

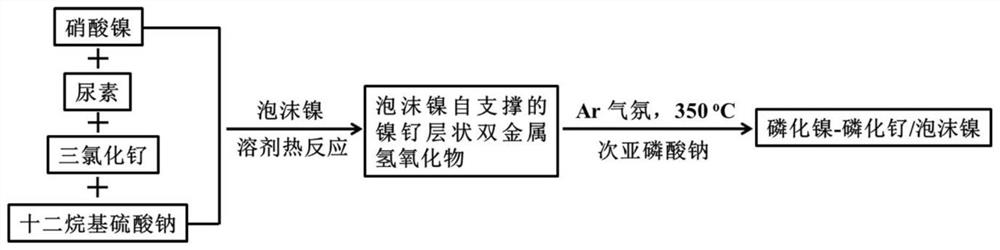

[0021] A kind of preparation method of nickel phosphide-ruthenium phosphide / foam nickel three-dimensional self-supporting electrode material of the present invention comprises the following steps:

[0022] 1) Preparation of nickel foam self-supporting nickel ruthenium layered double hydroxide (NiRu LDH): 2mmol nickel nitrate hexahydrate, 0.5mmol ruthenium trichloride, 0.5mmol sodium lauryl sulfate and 16.7mmol urea were dissolved in In 40mL water / ethylene glycol mixed solution (volume ratio 1:3), stir to obtain A solution, transfer it to a 50mL reaction kettle; immerse foamed nickel (length 2cm, thickness 150nm) in it; keep at 100°C for 12h, The nickel foam was washed five times with methanol and ultrapure water respectively, and vacuum-dried at 50°C to obtain sample I, which was the self-supporting nickel-ruthenium layered double hydroxide (NiRu LDH) of nickel foam;

[0023] 2) Preparation of nickel phosphide-ruthenium phosphide / nickel foam three-dimensional self-supporting e...

Embodiment 2

[0028] A kind of preparation method of nickel phosphide-ruthenium phosphide / foam nickel three-dimensional self-supporting electrode material of the present invention comprises the following steps:

[0029] 1) Preparation of nickel foam self-supporting nickel-ruthenium layered double hydroxide (NiRu LDH): 3 mmol of nickel nitrate hexahydrate, 0.75 mmol of ruthenium trichloride, 0.75 mmol of sodium lauryl sulfate and 25 mmol of urea were dissolved in 60 mL Water / ethylene glycol mixed solution (volume ratio 1:3), stir to obtain A solution, transfer it to a 100mL reactor; immerse foamed nickel (5cm in length, 150nm in thickness) in it; keep at 150°C for 12h, and place The nickel foam was washed five times with methanol and ultrapure water respectively, and vacuum-dried at 80°C to obtain sample I, which was the self-supporting nickel-ruthenium layered double hydroxide (NiRu LDH) of nickel foam;

[0030] 2) Preparation of nickel phosphide-ruthenium phosphide / nickel foam three-dimens...

Embodiment 3

[0032] A kind of preparation method of nickel phosphide-ruthenium phosphide / foam nickel three-dimensional self-supporting electrode material of the present invention comprises the following steps:

[0033] 1) Preparation of nickel foam self-supporting nickel ruthenium layered double hydroxide (NiRu LDH): 2.5mmol nickel nitrate hexahydrate, 0.6mmol ruthenium trichloride, 0.6mmol sodium lauryl sulfate and 20mmol urea were dissolved in In 50mL water / ethylene glycol mixed solution (volume ratio 1:3), stir to obtain A solution, transfer it to a 100mL reaction kettle; immerse foamed nickel (length 3cm, thickness 150nm) in it; keep at 120°C for 12h, Wash the nickel foam with methanol and ultrapure water for 5 times, and dry it in vacuum at 65°C to obtain sample I, which is the self-supporting nickel-ruthenium layered double hydroxide (NiRu LDH) of nickel foam;

[0034] 2) Preparation of nickel phosphide-ruthenium phosphide / nickel foam three-dimensional self-supporting electrode mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com