A system and method for preparing polysilicon aluminum sulfate water purifying agent

A polysilicon aluminum sulfate, water purifying agent technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of slow addition of alkali, high temperature digestion, slow heating, etc. Achieve the effect of improved mass transfer efficiency, good stability and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

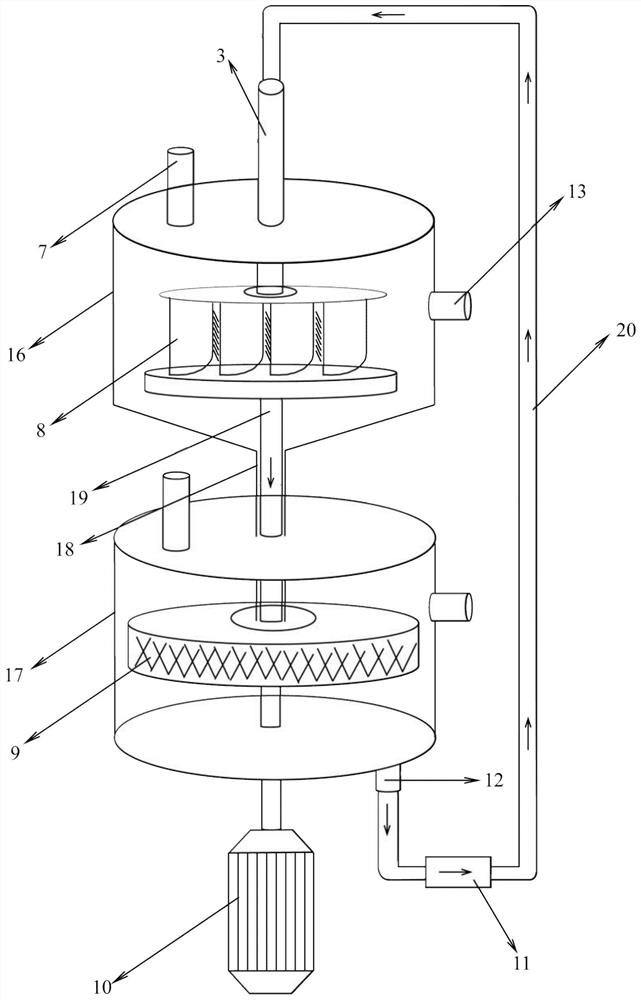

[0045] Utilize above-mentioned system to prepare the method for polysilicon aluminum sulfate water purifying agent, specifically comprise the following steps:

[0046] Step 1: Pre-prepared 600kg of saturated aluminum sulfate solution (liquid A), 100kg25% (SiO 2 content) of water glass solution (B liquid) and 66kg sodium aluminate saturated solution (C liquid);

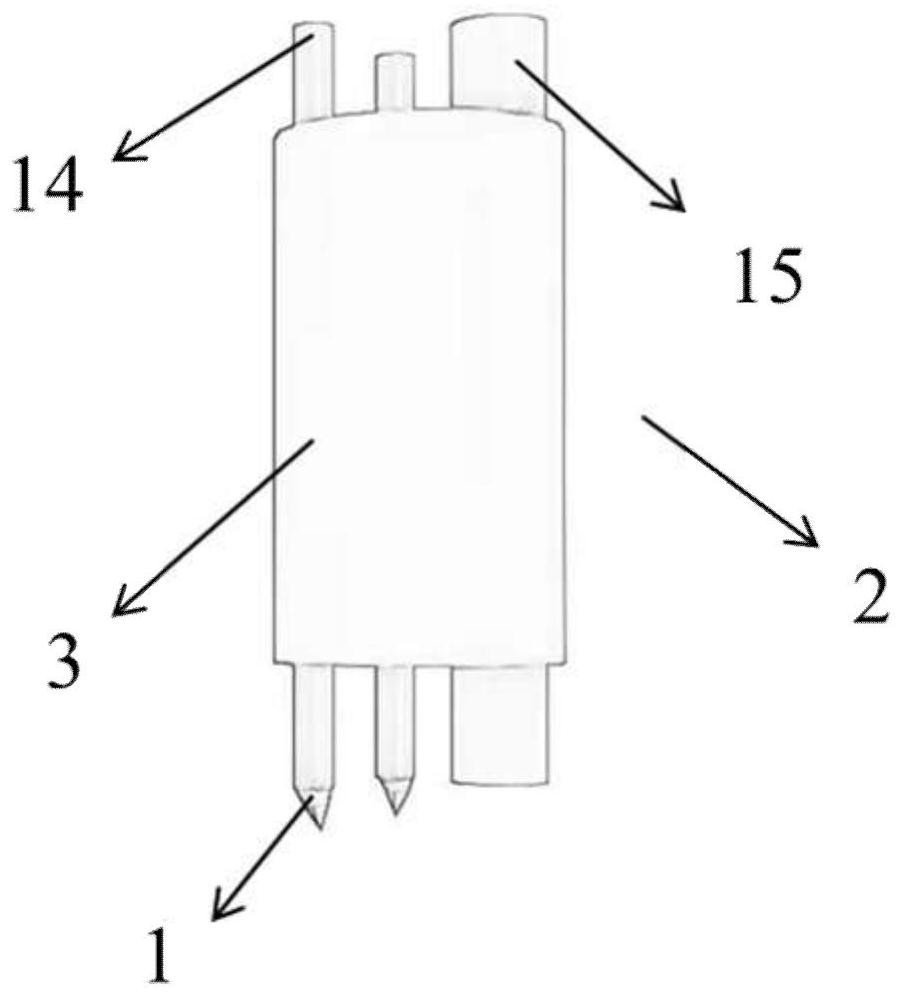

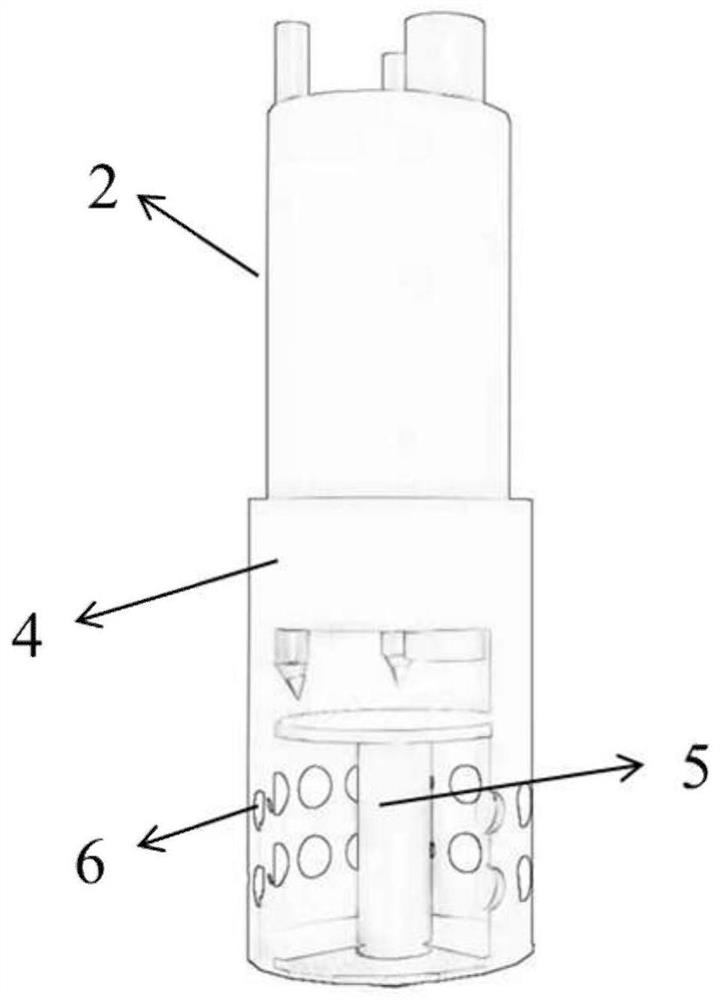

[0047] Step 2: Set and adjust the rotor speed of the supergravity machine to 3000r / min, adjust the liquid flow rate of the two vertical spray pipes in the liquid distributor of the supergravity machine according to the pre-calculated dosing ratio, and the two vertical spray pipes within 10min The straight spray pipe sprays the corresponding solution;

[0048] Step 3: At room temperature, respectively spray liquid B and liquid C into the premixing pipe through a vertical spray pipe in the liquid distributor, and spray them with another vertical spray pipe in the liquid distributor. The liquid A sprayed by tube atomiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com