Intelligent silkworm cocoon sorting method

A cocoon and cocoon sorting technology, applied in the field of silk reeling industry, can solve the problems of poor detection reliability and cocoon sorting reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

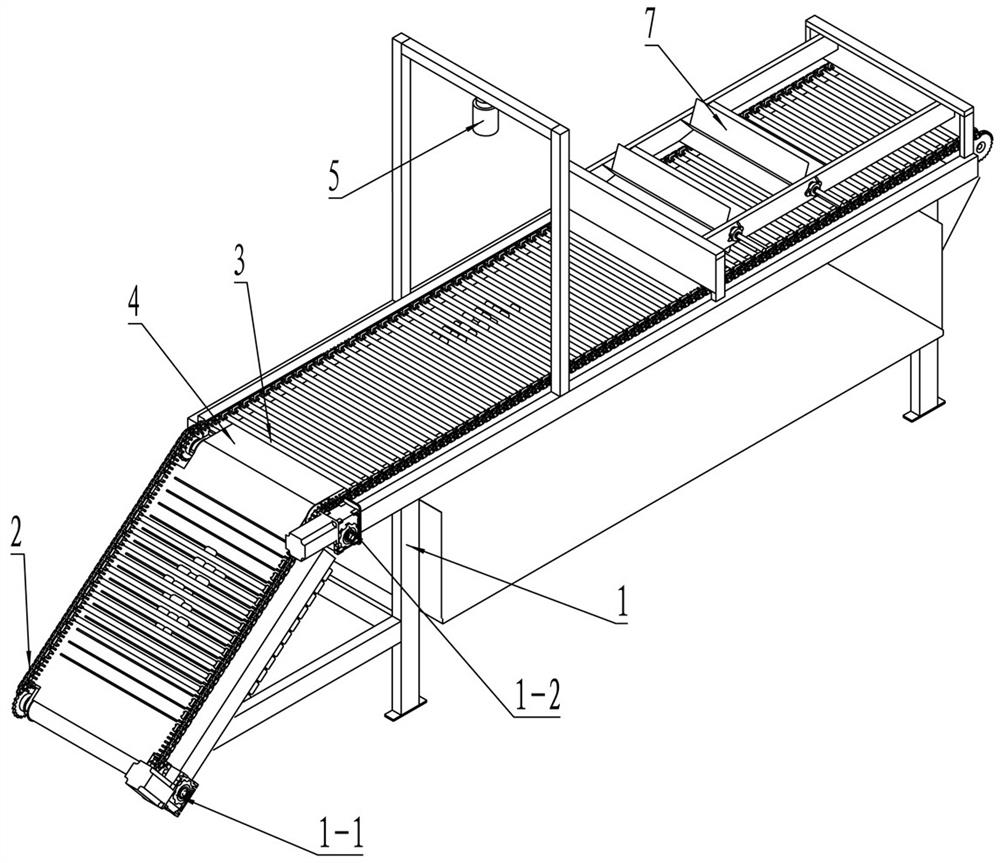

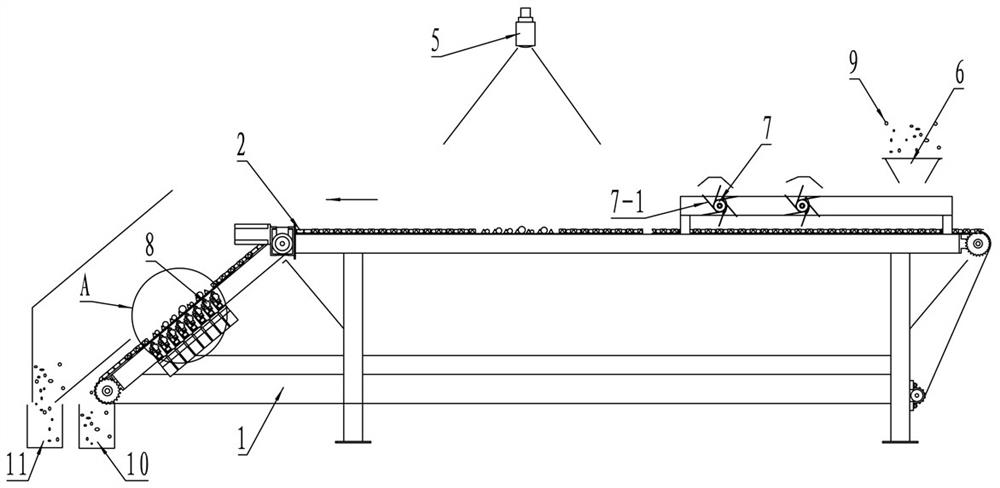

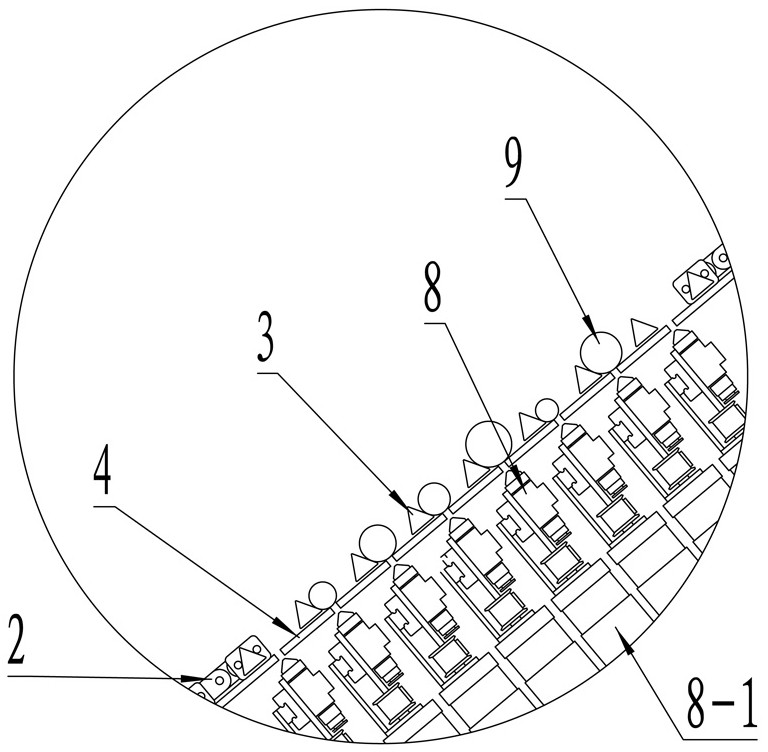

[0042] The intelligent cocoon sorting method includes sorting cocoons by using a cocoon-blowing type cocoon intelligent sorting machine. Such as figure 1 , figure 2 , image 3 The cocoon-absorbing cocoon intelligent sorting machine shown includes a conveyor belt driven by a power machine on frame 1, two conveyor belts stacked up and down, the front section of the two conveyor belts in the conveying direction is horizontal, and the rear section is inclined downward.

[0043] The upper conveyor belt is a chain conveyor chain 2 that moves forward and non-uniformly in the same direction as the conveyor belt, and the lower conveyor belt is a belt conveyor belt 3 that moves forward and backward in the same direction as the conveyor belt and then reverses. The belt drives the power machine 1-2 drives the belt conveyor belt 4 to run, the chain drive power machine 1-1 drives the chain conveyor chain 2 to run, the belt drive power machine 1-2 and the chain drive power machine 1-1 are...

Embodiment 2

[0051] The method for intelligently sorting silkworm cocoons comprises using a cocoon-suction type intelligent cocoon sorting machine to sort silkworm cocoons.

[0052] Such as Figure 4 , Figure 5 , Figure 6 The cocoon-absorbing cocoon intelligent sorting machine shown includes a conveyor belt driven by a power machine on the frame 21, two conveyor belts are stacked up and down, and the conveyor belt above is a positive non-uniform motion with the same conveying direction. The chain conveyor chain 22, the conveyor belt below is the belt conveyor belt 23 of forward and reverse reciprocating motion opposite to the same as the conveyor belt conveying direction, and the belt drive power machine 21-2 drives the belt conveyor belt 24 to run, and the chain drives the power machine 21-1 Driving chain conveying chain 22 runs, and belt driving power machine 21-2 and chain driving power machine 21-1 are servo motors; The chains of chain conveying chain 22 are arranged side by side w...

Embodiment 3

[0058] The silkworm cocoon intelligent sorting method comprises the use of a silkworm cocoon intelligent sorting machine to sort silkworm cocoons. like Figure 7 The cocoon-suction intelligent cocoon sorting machine shown has the same structure as the first embodiment, except that a suction device 38 is provided at the position where the conveyor belt is below the cocoon image collector. The suction device includes a longitudinal guide rail 38-1, a longitudinal guide rail 38 -1 is provided with a horizontal guide rail 38-3 driven by a motor 38-2, and the horizontal guide rail 38-3 is driven by a motor 38-4 to be provided with six vertically arranged cylinders 38-5, and the bottom of each cylinder 38-5 Suction cup 38-6 is provided; the end of the rear section of the conveyor belt is inclined downwards to be provided with a qualified product box 310, and there are two unqualified product boxes 311, one is located at a position where the qualified product box 310 is away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com