Double-layer milk cover essence matrix and preparation method thereof

A technology of essence and milk cap, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc. It can solve the problem of reducing the viscosity of dispersion solvents, detrimental to the stability of the double-layer milk cap essence matrix, and the inability to add polymers to thicken agent and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

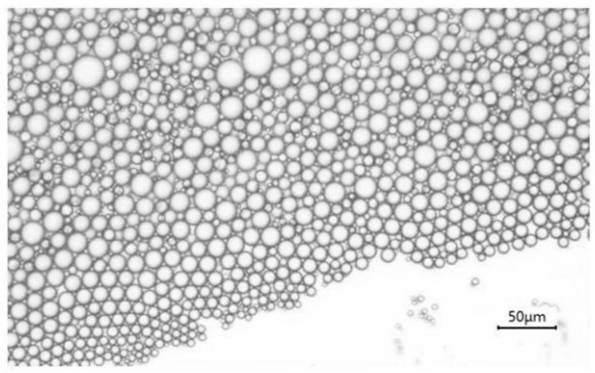

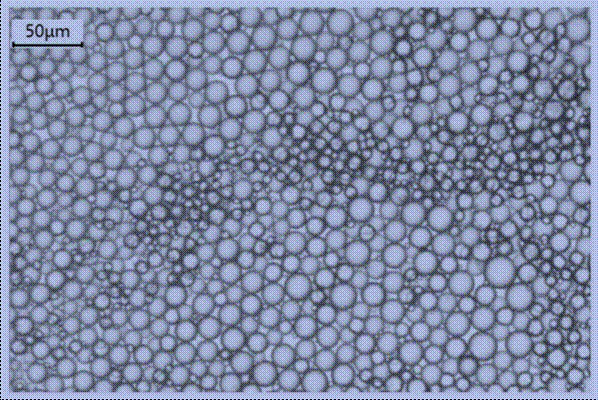

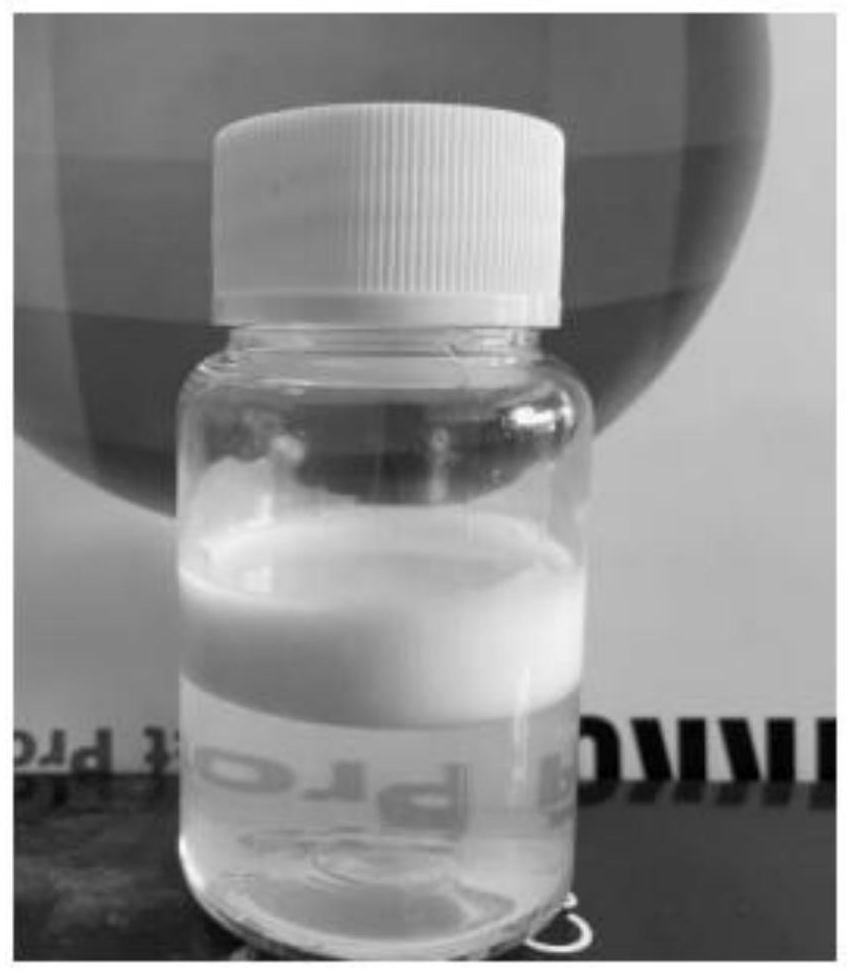

Image

Examples

Embodiment 1

[0045] This example examines the effect on the stability of the matrix when the ratio of sucrose laurate and laureth-23 added to the double-layer milk cap essence matrix is 0.5%:0.5%. The components and percentage contents of the double-layer milk cap essence matrix forming the present embodiment are shown in the following table:

[0046]

[0047]

[0048] The preparation method of the above double-layer milk cap essence matrix includes the following steps: mix Ryto Sugar Ester L-1695 with the polyol in the formula evenly at a temperature of 60°C, and the stirring speed is 200-300rpm, and the outside is completely wetted Then heat to 75-85°C until slightly viscous and transparent (it is also recommended to infiltrate in advance to help dissolve evenly); dissolve ALKONATL230 and other water-soluble ingredients in phase A in the remaining water phase; heat to 75-85°C; Under the temperature, add phase B into the water phase for emulsification, homogenize for 5-10 minutes, a...

Embodiment 2

[0050] This example examines the effect on the stability of the matrix when the ratio of sucrose laurate and laureth-23 added to the double-layer milk cap essence matrix is 0.1%:0.9%. The components and percentage contents of the double-layer milk cap essence matrix forming the present embodiment are shown in the following table:

[0051]

[0052] The preparation method of the above-mentioned double-layer milk cap essence liquid matrix is consistent with the preparation method of Example 1.

Embodiment 3

[0054] This example examines the effect on the stability of the matrix when the ratio of sucrose laurate and laureth-23 added to the double-layer milk cap essence matrix is 0.2%:0.8%. The components and percentage contents of the double-layer milk cap essence matrix forming the present embodiment are shown in the following table:

[0055]

[0056] The preparation method of the above-mentioned double-layer milk cap essence liquid matrix is consistent with the preparation method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com