Spiral discharging device for three-dimensional cage culture equipment

A technology of spiral discharge and cage breeding, which is applied in application, poultry farming, animal husbandry, etc., can solve the problems of feeding pipe blockage, low benefit creation, and low breeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

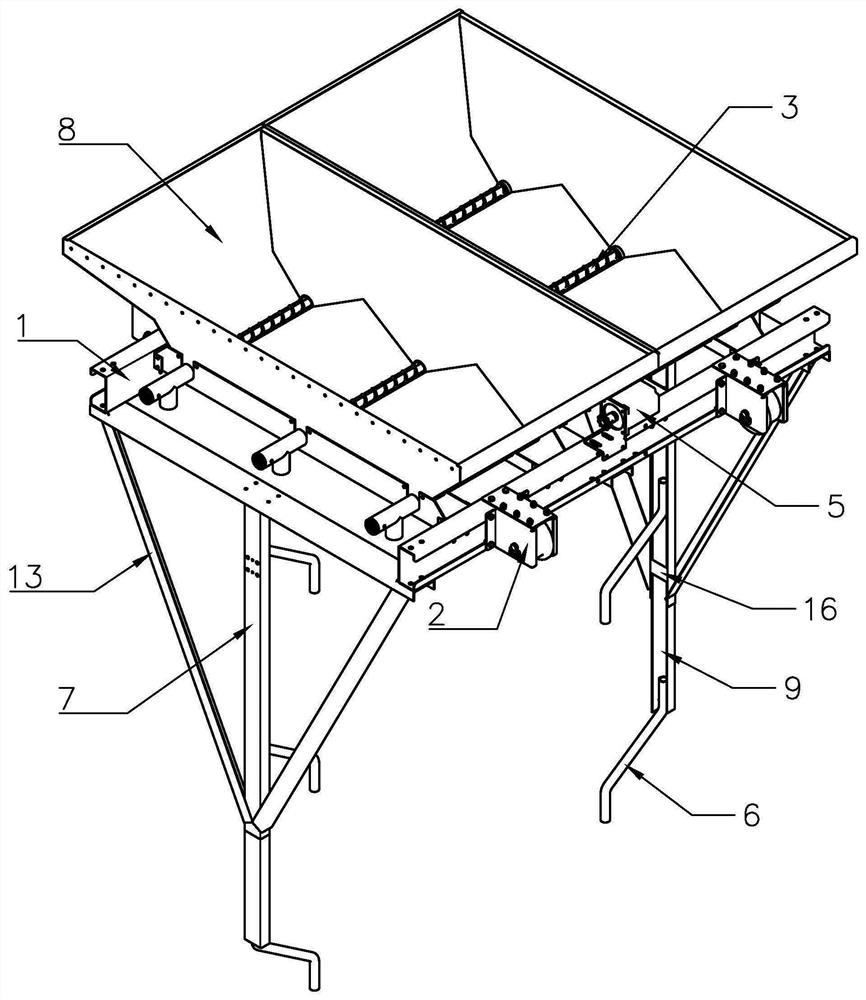

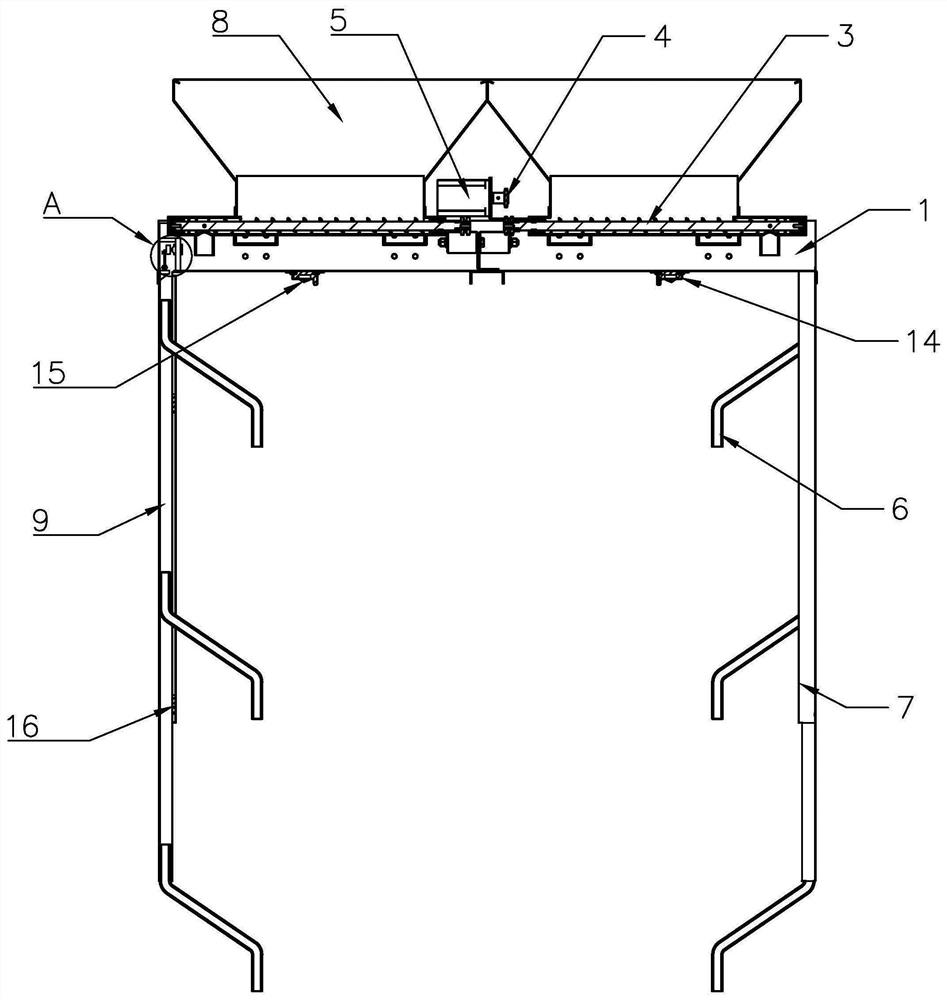

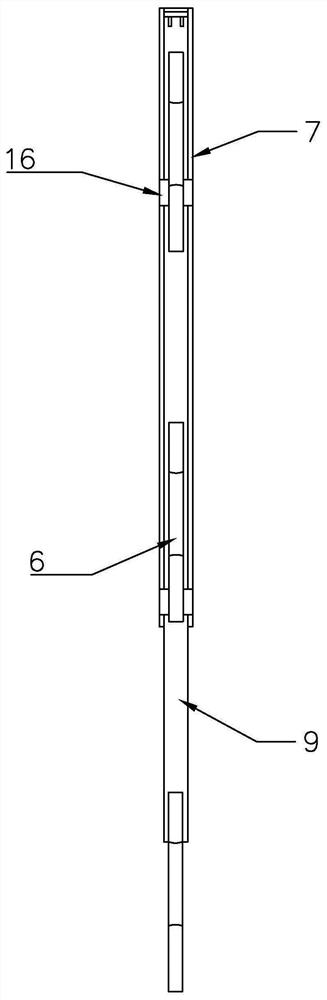

[0021] Such as Figure 1-7 As shown, a screw discharge device for three-dimensional cage equipment includes a walking frame 1 and a plurality of support rollers 2 for supporting the walking frame 1 to walk. The walking frame 1 is driven to move by the driving equipment on the three-dimensional chicken cage, and the supporting rollers 2. There are four in total, and they are evenly arranged and fixed on the front and rear sides of the walking frame 1. The walking frame 1 is provided with multiple groups of left and right symmetrical spiral conveying augers 3, and each group of spiral conveying augers 3 is conveyed outward. The inner end of the rotating shaft of the conveying auger 3 is respectively fixed with a sprocket 4, and the sprocket 4 on the right side or the same left side is driven to rotate by the same reduction motor 5 and a chain, and the feeding port at the outer end of each screw conveying auger 3 Connect with the upper ends of the same-side feeding pipes 6 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com