In-situ measurement system and method for low-temperature molded surface of key component of low-temperature equipment

A low-temperature equipment, in-situ measurement technology, applied in the direction of mechanical valve testing, etc., can solve problems such as poor cooperation, low-temperature equipment stuck, failure to find the cause of failure, etc., to save time and avoid inaccurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

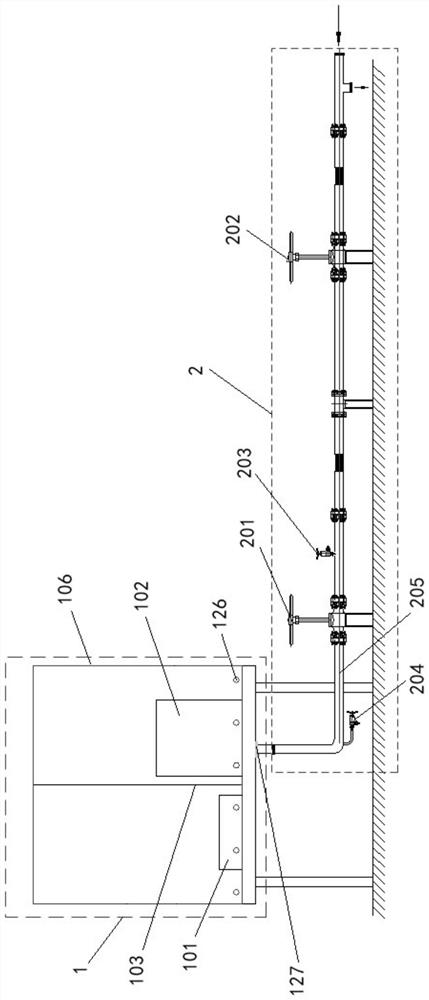

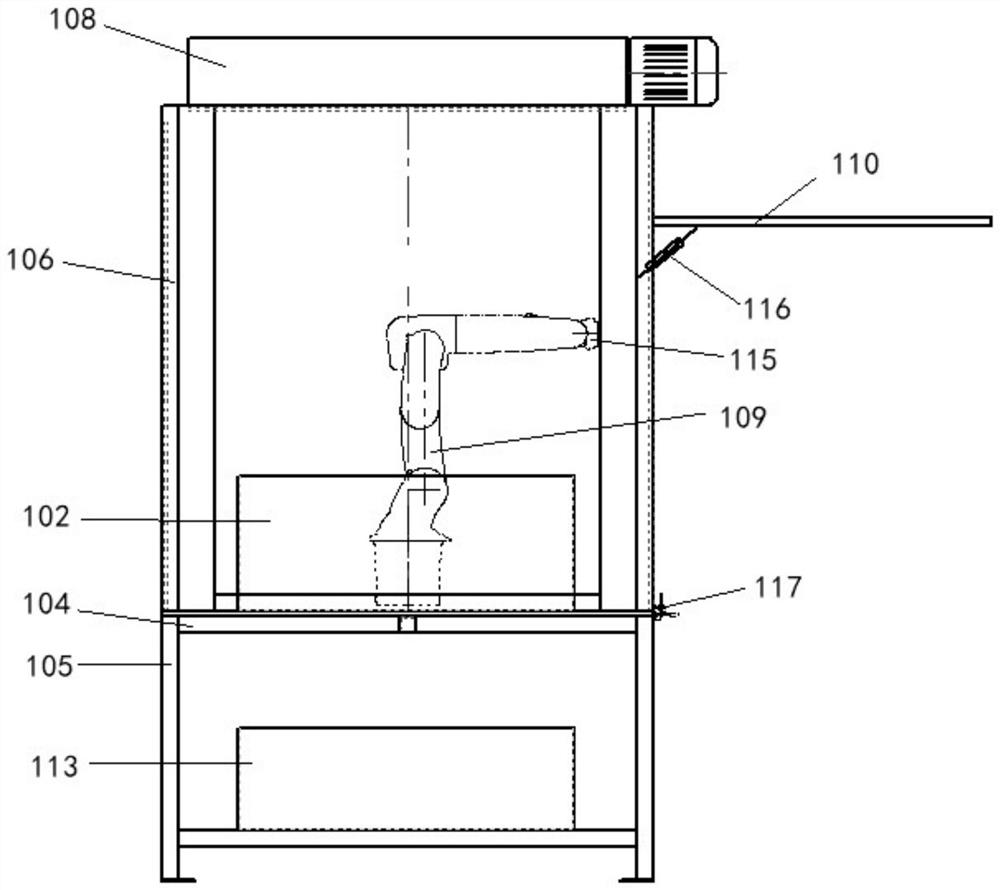

[0054] See Figure 1 - Figure 5 The low temperature equipment key assembly provided by this embodiment is a low temperature surface in place measuring system, including test unit 1 and a low temperature liquid nitrogen supply system 2;

[0055] The test unit 1 includes a transparent heat shroud 106, a first surface 104, a robot measuring unit and a liquid nitrogen low temperature cooling unit disposed on the first surface 104.

[0056] A plurality of support frames 105 are provided in the first surface 104, and a second plan for fixing the support frame 105 is provided under the first surface 104;

[0057] The transparent insulation cover 106 is sealed with the first surface 104 for isolation of the robot measuring unit and the liquid nitrogen cryogenic cooling unit; the transparent heat housing 106 is provided with a switched active door 110; the movable door 110 can be opened The position of the active door 110 is made, and the operator is closed after performing the relevant ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com