Small potato combine harvester

A combine harvester and potato technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of incompletely broken clods, affecting the quality and market price of potatoes, and affecting the quality of potatoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

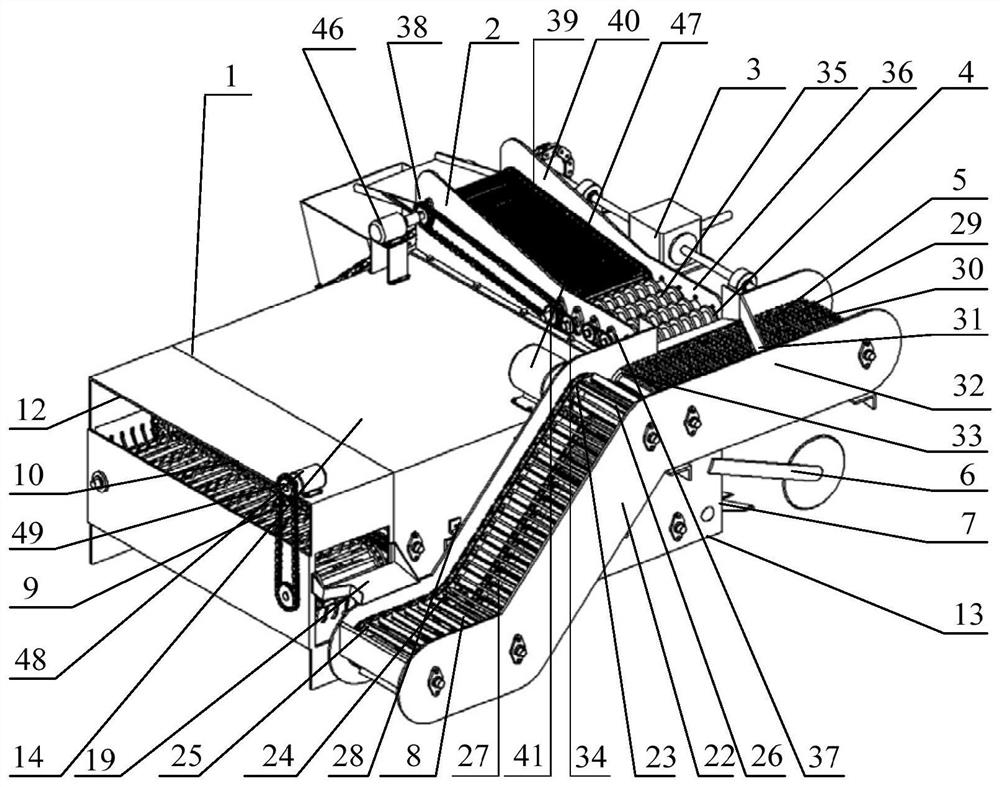

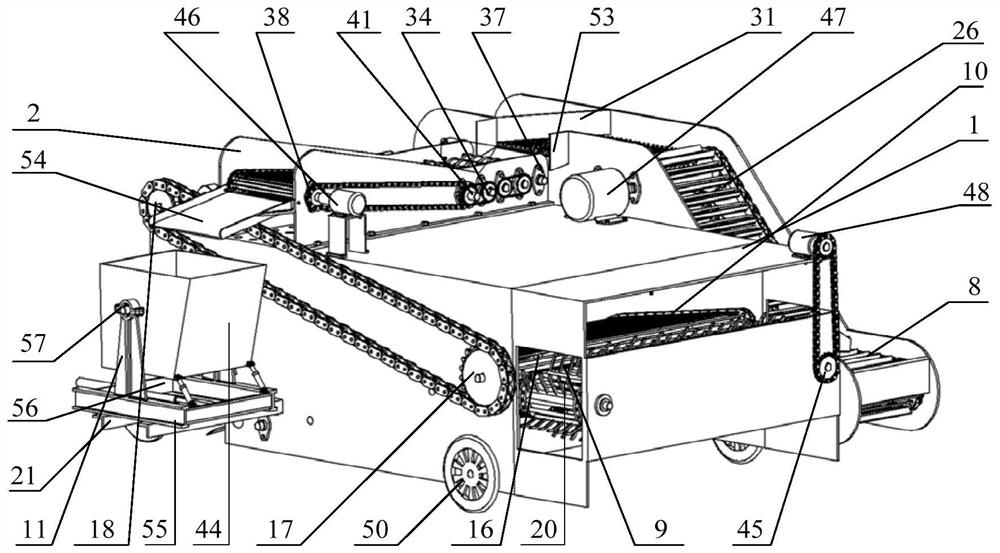

[0036] combine figure 1 and figure 2, the small-sized potato combine harvester that the embodiment of the present invention provides, its frame 1 is made of left side plate 12, right side plate 13 and top plate 14, and frame bottom has four wheels 50; The front end of the side plate 13 is equipped with a soil cutting device 6; an excavation device 7 is installed at the front end of the frame 1; the harvester has six conveying separation devices; the harvester is provided with a potato collection device 11.

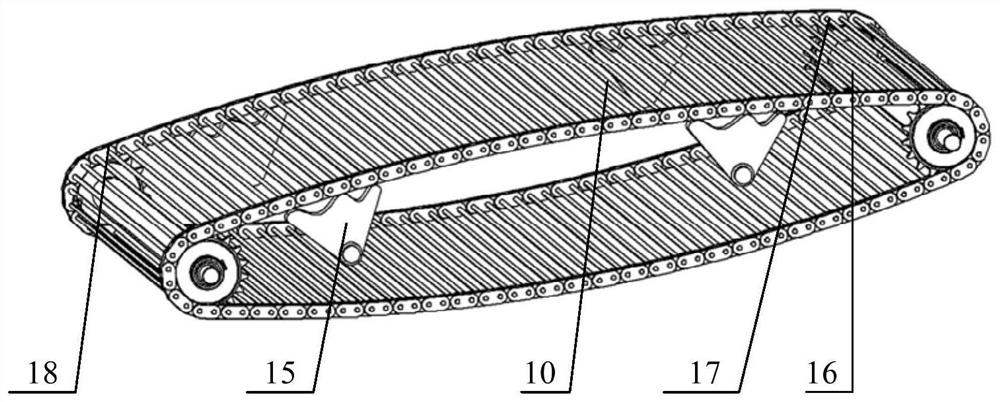

[0037] The six-stage conveying and separating device includes a primary conveying and separating device 10 , a secondary conveying and separating device 9 , a third-stage conveying and separating device 8 , a fourth-stage conveying and separating device 5 , a fifth-stage conveying and separating device 4 and a sixth-stage conveying device 2 .

[0038] combine F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com