Pentaerythritol ester base oil and preparation method thereof

A technology of pentaerythritol ester and pentaerythritol, which is applied in the field of preparation of pentaerythritol ester base oil, can solve the problems of poor compatibility, esterification process to be optimized, long esterification reaction time, etc., achieve good compatibility, optimize esterification process, The effect of shortening the reaction time of esterification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of pentaerythritol ester base oil, comprises the following steps:

[0022] a) mixing isooctanoic acid and pentaerythritol to obtain a mixture;

[0023] b) adding a catalyst to the mixture obtained in step a) to carry out the first esterification reaction; adding fatty acid to carry out the second esterification reaction to obtain pentaerythritol crude esters, which are refined to obtain pentaerythritol ester base oils.

[0024] In the present invention, firstly, isooctanoic acid and pentaerythritol are mixed to obtain a mixture. In the present invention, the isooctanoic acid and pentaerythritol can be obtained from commercial sources well known to those skilled in the art. In the present invention, the molar ratio of isooctanoic acid to pentaerythritol is preferably (1.5-3.5):1, more preferably (2-3):1.

[0025] In the present invention, the process of said mixing is preferably specifically:

[0026] Under the condi...

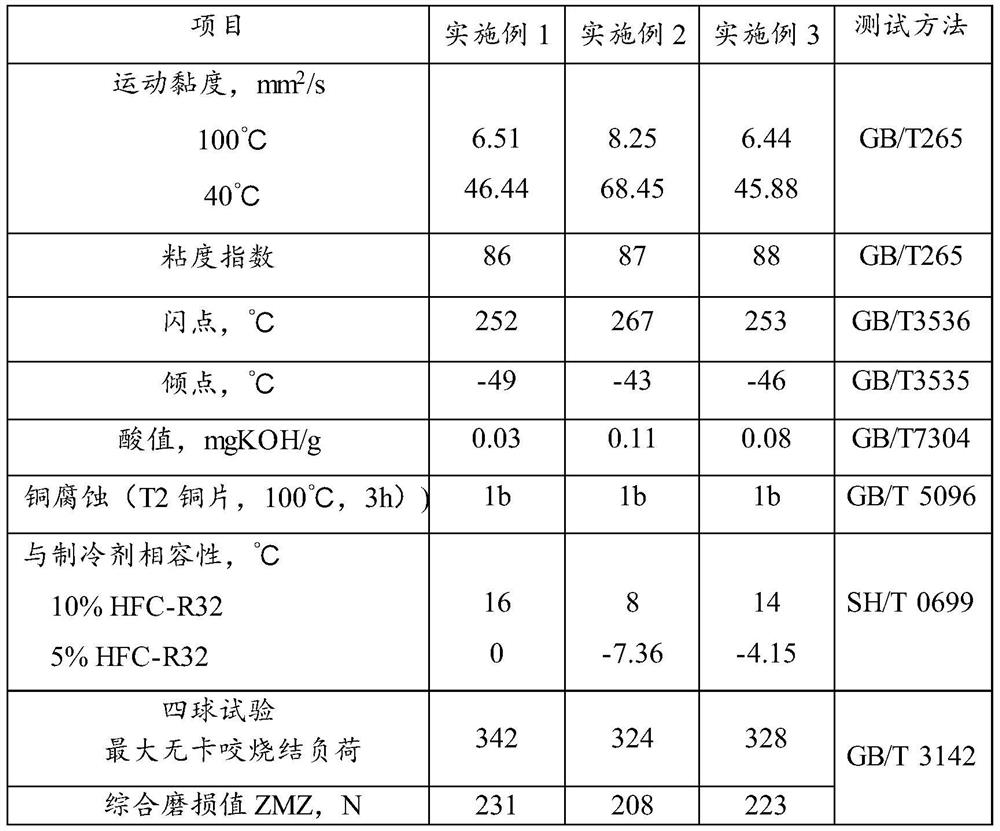

Embodiment 1

[0048] Under the condition of stirring at a rotating speed of 100r / min, mix isooctanoic acid and pentaerythritol with a molar ratio of 2:1 in the reactor, then heat up to 90°C and keep it for 1h to obtain the mixture; then add 0.15% (wt) of the above mixture The sulfur-based catalyst produced by Yucheng Chemical Co., Ltd. carries out the esterification reaction at 200°C, and the reaction time is 3 hours; when the water output of one-step esterification reaches the theoretical water output, it means that the one-step esterification reaction is complete; when the temperature is lowered to below 120°C, Add isovaleric acid, the molar ratio of which to pentaerythritol is 2.2:1, and continue the esterification reaction at 200°C for 5 hours to obtain crude pentaerythritol ester, which is refined to obtain pentaerythritol ester base oil.

Embodiment 2

[0050] Under the condition of stirring at a rotating speed of 100r / min, mix isooctanoic acid and pentaerythritol with a molar ratio of 2:1 in the reactor, then heat up to 90°C and keep it for 1h to obtain the mixture; then add 0.15% (wt) of the above mixture The sulfur-based catalyst produced by Yucheng Chemical Co., Ltd. carries out the esterification reaction at 200°C, and the reaction time is 3 hours; when the water output of one-step esterification reaches the theoretical water output, it means that the one-step esterification reaction is complete; when the temperature is lowered to below 120°C, Add isononanoic acid, the molar ratio of which to pentaerythritol is 2.2:1, and continue the esterification reaction at 200°C for 5 hours to obtain crude pentaerythritol ester, which is refined to obtain pentaerythritol ester base oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com