Rapid drying assembly line for printed articles

A rapid drying and assembly line technology, applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of unable to adapt to plate-shaped paper boards, low conveyor belt spacing, etc., to achieve active gas flow, good diffusion of hot air , Enhance the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached figure 1 to attach Figure 7 Shown:

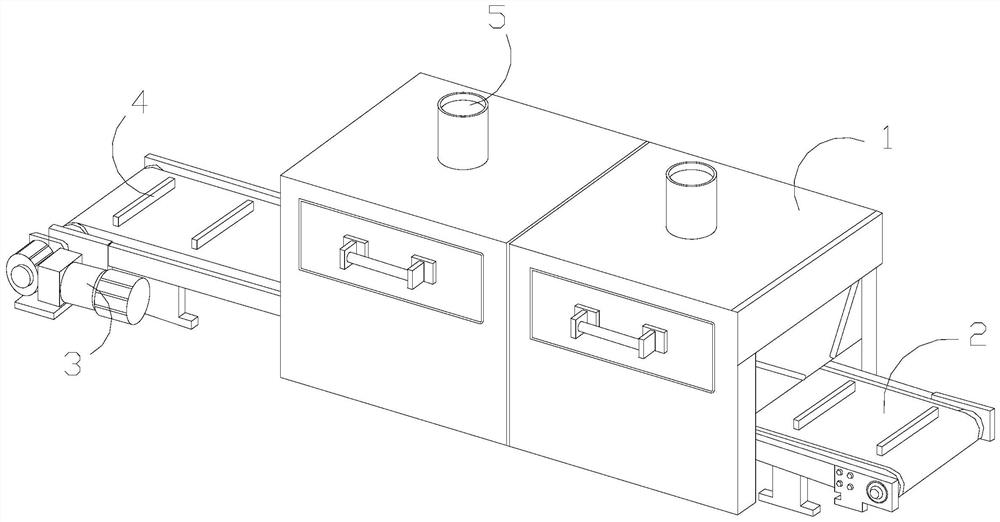

[0032] The present invention provides a quick drying assembly line for printed articles. Its structure is provided with a drying box 1, a conveyor belt 2, a total power 3, a positioning rod 4, and an exhaust port 5. The conveyor belt 2 runs through the inside of the drying box 1. The total power 3 is installed at one side of the conveyor belt 2, the positioning rod 4 and the conveyor belt 2 are integrated, and the exhaust port 5 and the drying box 1 are integrated and connected.

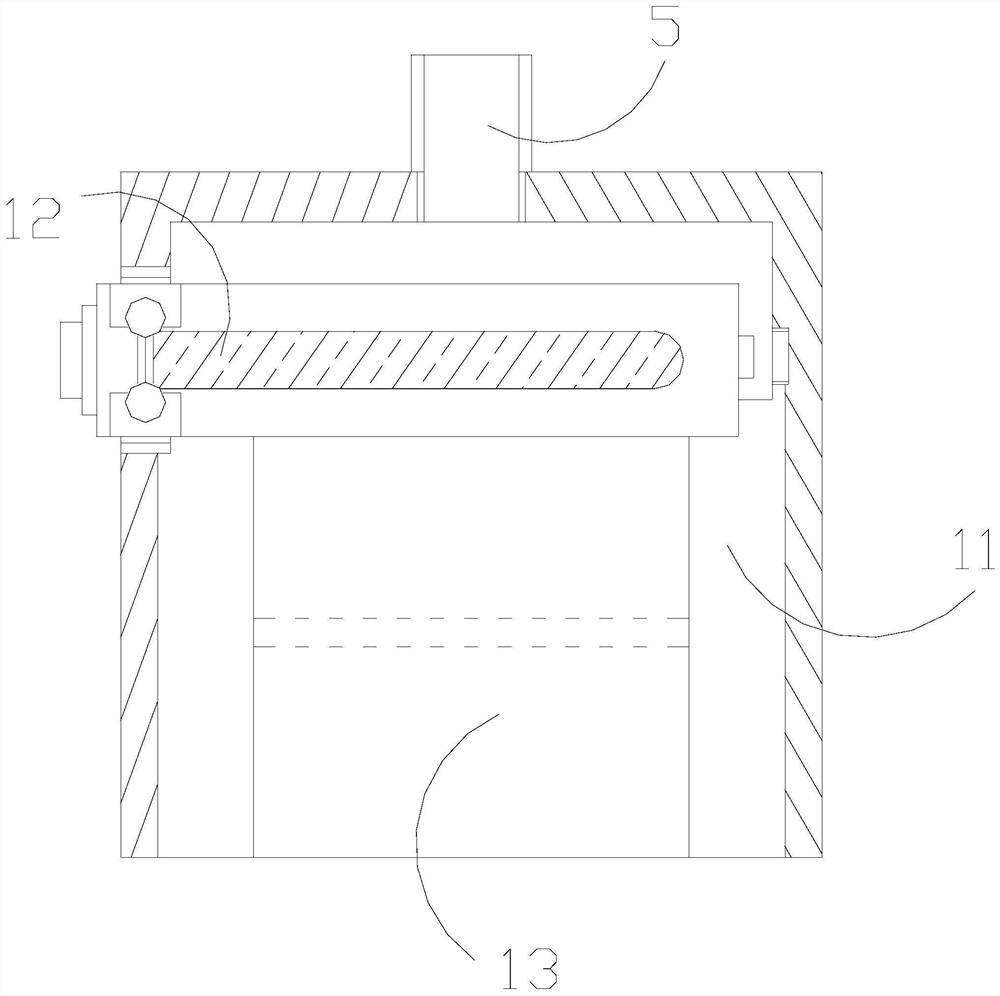

[0033] The drying box 1 is provided with a box frame 11, a heat-producing plate 12, and a passage port 13. The box frame 11 and the drying box 1 are an integrated structure, and the heat-producing plate 12 is embedded in a part of the box frame 11. In the upper position, the passage port 13 is located below the heat generating plate 12 .

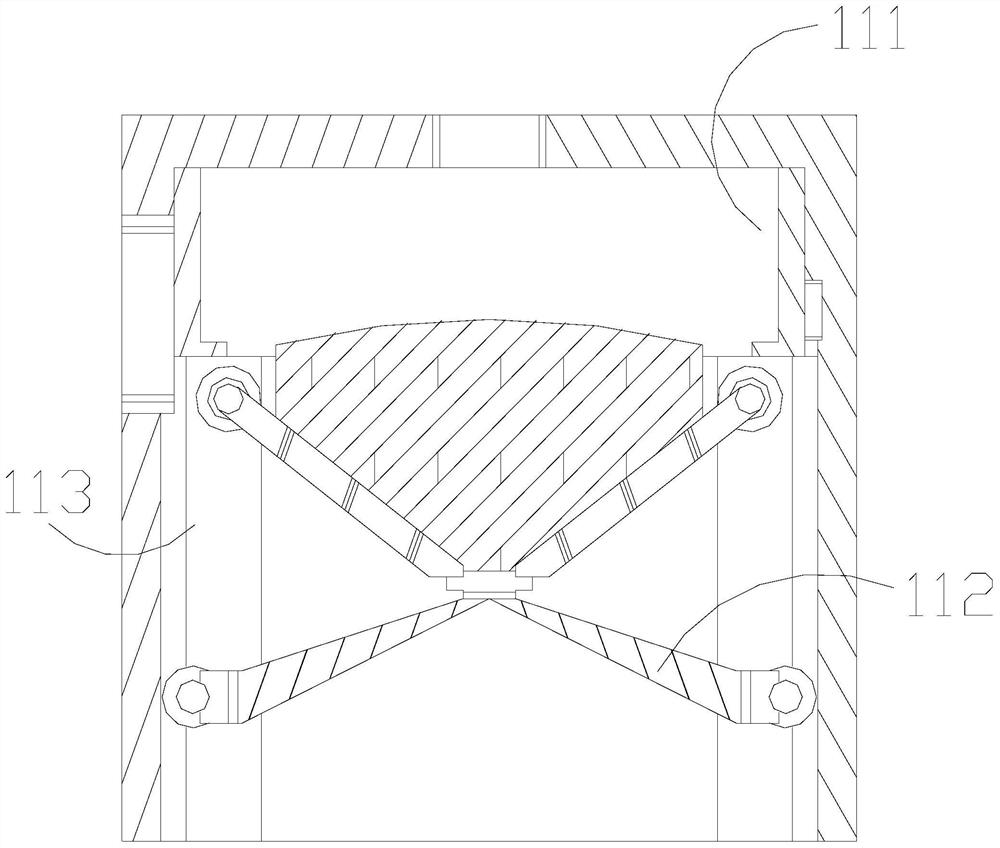

[0034] Wherein, the box frame 11 is provided with a plate top 111, a movable frame 112, and a side cavi...

Embodiment 2

[0041] as attached Figure 8 to attach Figure 9 Shown:

[0042] Wherein, the abutting plate a1 is provided with a solid plate a11, a motion-assisting ball a12, and a hinge pulley a13, the hinge pulley a13 is movably connected to the lower end of the solid plate a11, and the motion-assisting ball a12 is movably installed on the front end surface of the solid plate a11 Above, there are two assisting balls a12, and they are of spherical structure. Under the action of contact with foreign objects, the assisting balls a12 can be displaced and rotated to a certain extent, so as to generate driving force.

[0043] Wherein, the assisting ball a12 is provided with a swivel e1 and a collision spring e2, the front end of the collision spring e2 is connected with the outer side of the swivel e1 in a gap fit and is movably matched, the swivel e1 is a ring structure, and the collision spring e2 is arc-shaped, has elastic force, and can be deformed in the arc direction, and the collision ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com