Fabricated building wallboard compression molding equipment

A molding and assembly technology, which is applied in the direction of forming pressure head, ceramic molding machine, mold, etc., can solve the problems that the wallboard is not easy to separate from the mold, cannot be ejected from the wallboard, and cannot be molded into the wallboard, so as to ensure the processing Quality effect, beneficial to subsequent use, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

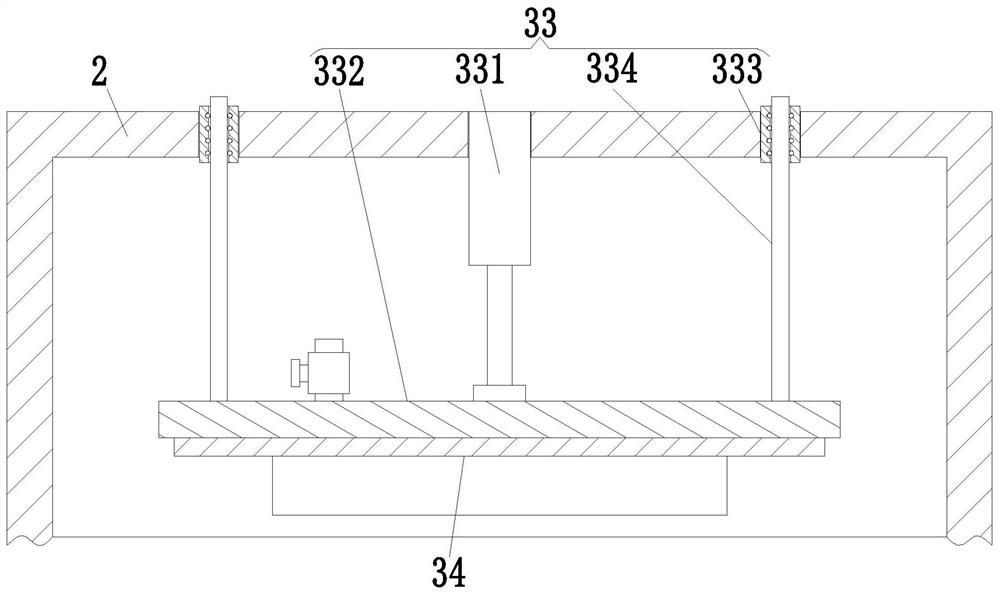

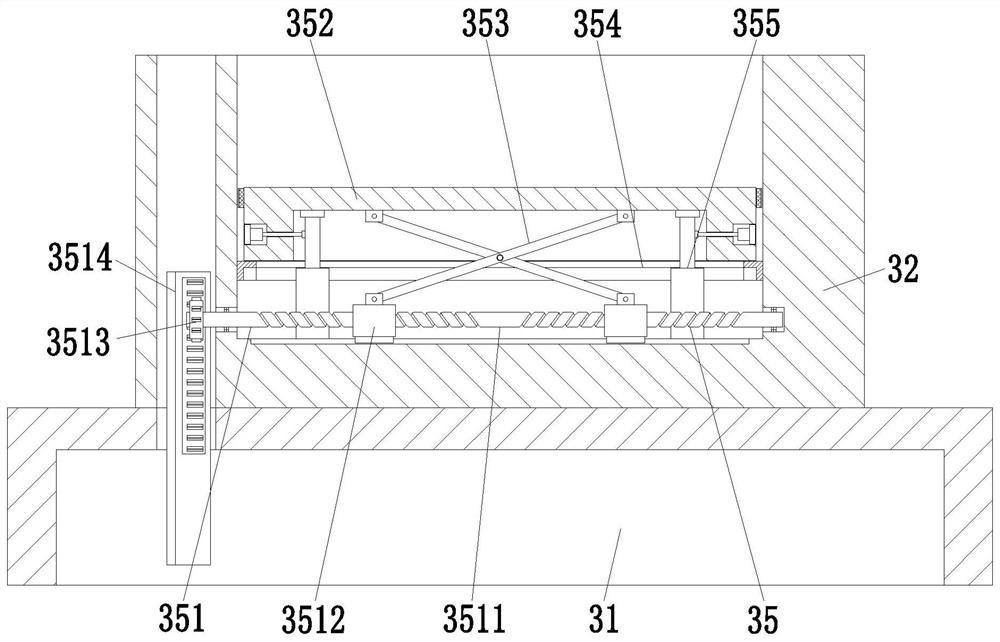

[0028] like Figure 1 to Figure 6 As shown, a prefabricated building wall panel molding equipment includes a base plate 1, a housing frame 2 and a molding device 3, the upper end of the base plate 1 is equipped with a housing frame 2, and the section of the housing frame 2 is a U-shaped structure. A molding device 3 is installed inside the housing frame 2 , and the lower end of the molding device 3 is installed on the base plate 1 .

[0029] The molding device 3 includes a frame 31, a fixed mold frame 32, a drive mechanism 33, a movable mold frame 34 and an adjustment mechanism 35. The lower end of the housing frame 2 is provided with a frame 31, and the frame 31 is installed on the bottom plate 1, a fixed formwork 32 is installed on the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com