Design method for built-in foundation of high and steep slope bridge

A technology for high and steep slopes and design methods, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as poor engineering economy, not scientific enough, and too conservative, so as to promote the use, reduce slope protection projects, reduce The effect of bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

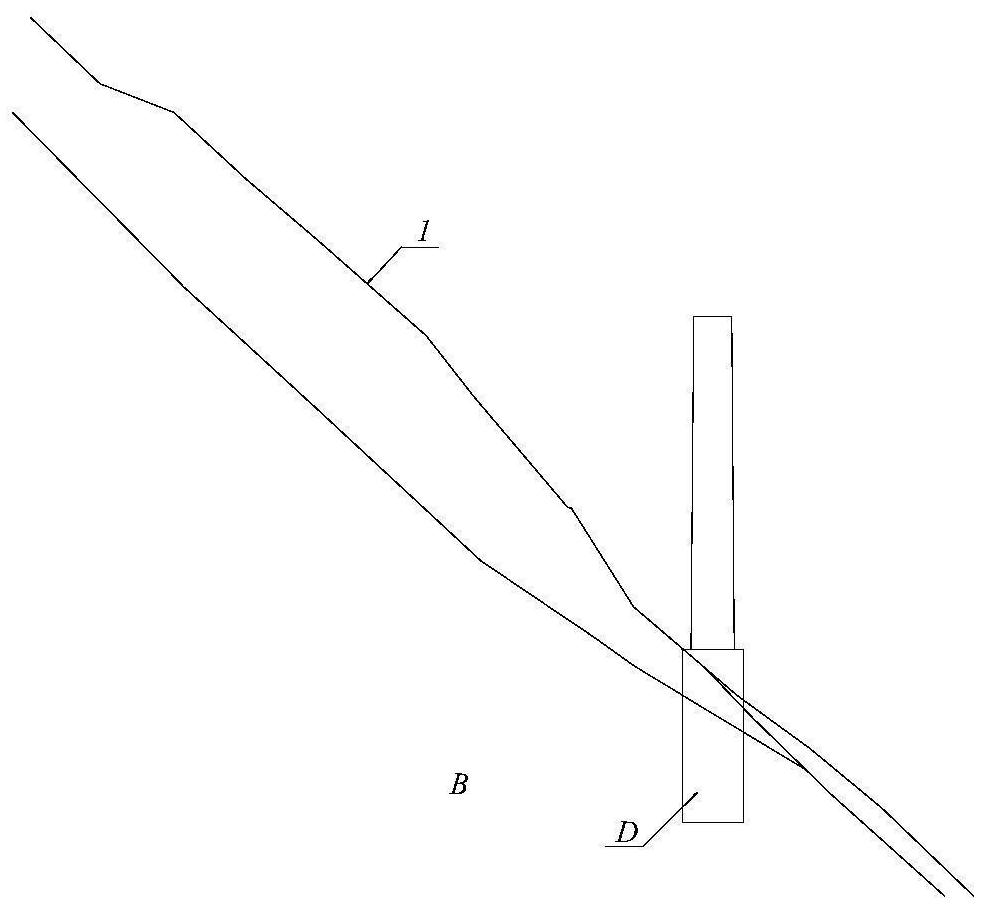

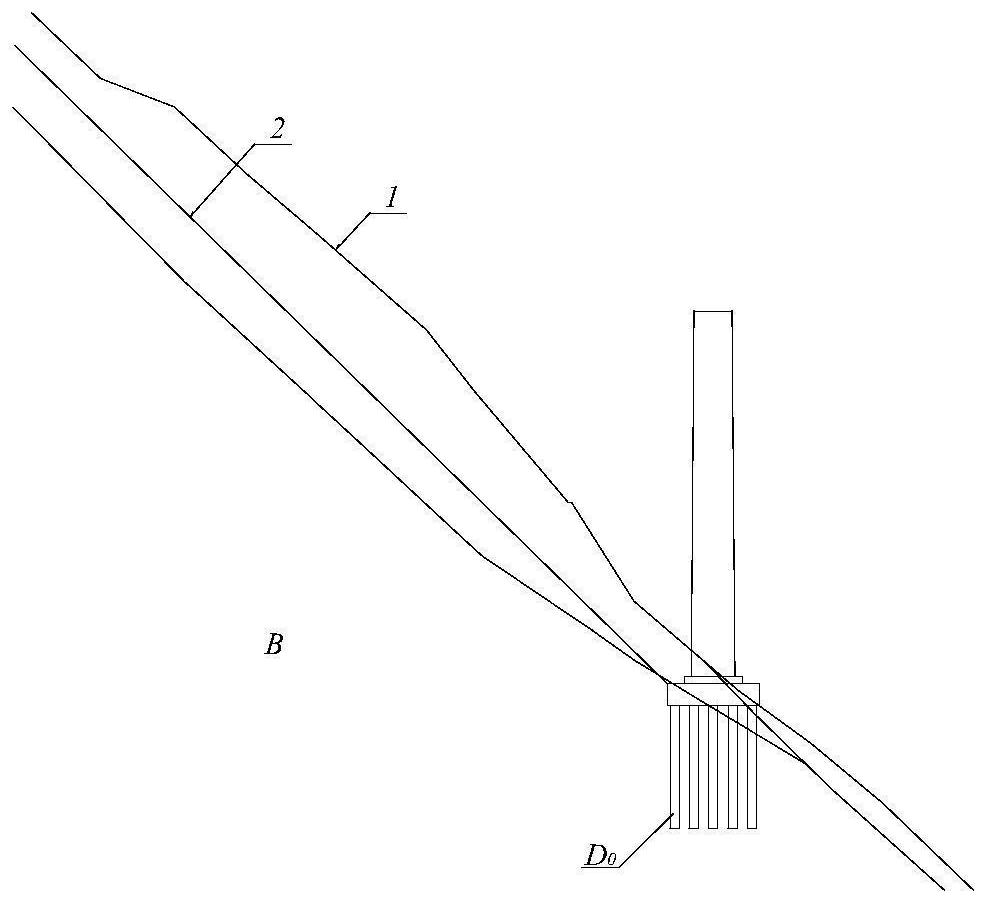

[0042] According to the stress mode of the embedded foundation and the failure form of the mountain, the present invention divides the stressed area and the geological area of the embedded foundation D on the steep slope. Divide the stressed area of embedded foundation D into free section D1, sidewall constrained section D2 and embedded section D3, and divide the geological area into soil and rock shear failure area B1 and embedded area B2.

[0043] refer to image 3 , the free section D1 is an area that is easy to be disturbed and damaged in soil or rock construction, has poor rock quality, and is partially suspended. It provides less constraints on the embedded foundation, and its force is generally not considered in the design.

[0044] The side wall restraint section D2 is the possibility of shear failure of the front end soil under the externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com