Drilling and tamping integrated long spiral drilling machine and drilling and tamping method

A long auger, long helix technology, applied in drilling equipment and methods, rotary drills, impact drilling and other directions, can solve the problem of not effectively improving construction efficiency and pile quality, limiting the use of long auger Reduce the high requirements of construction equipment and other problems, and achieve the effect of reducing the cost of construction equipment and time, widening the scope of construction, and ensuring the quality of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

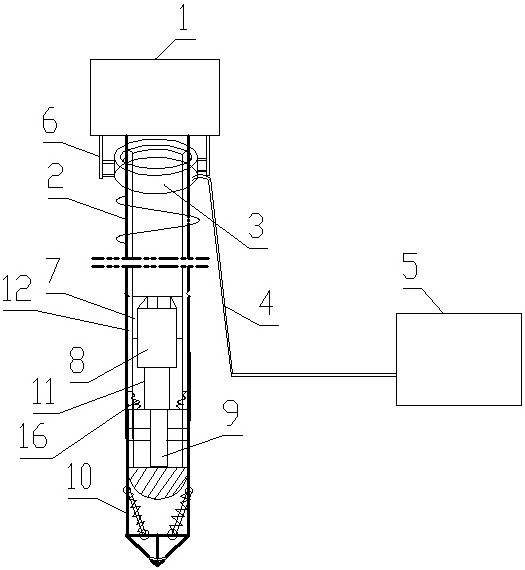

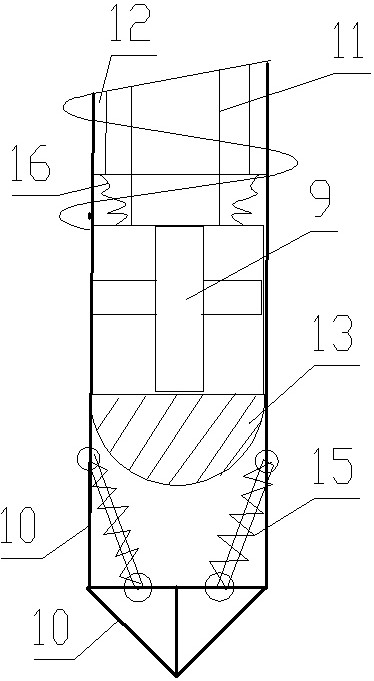

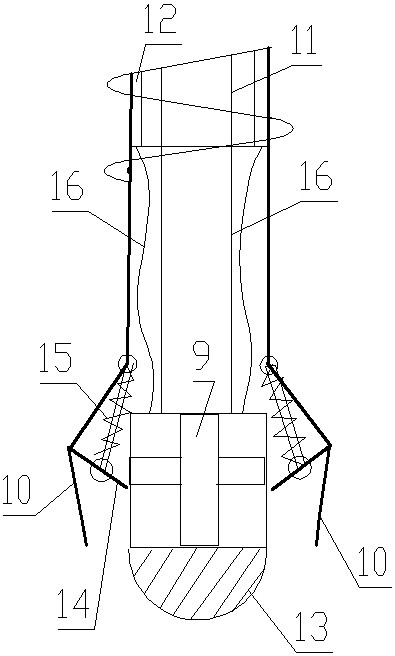

[0032] Such as Figure 1 to Figure 3 As shown, the long auger drilling rig integrated with drilling and compaction of the present invention is a mechanical device for completing the construction of cast-in-situ piles, including a chassis assembly, which has a traveling mechanism and a rotary table, and the rotary table is provided with a drilling tower and a driver's cab. The drilling tower is hoisted with a power head 1 through a suspension rope and a movable pulley device, and the power head 1 is used to move up and down along the tower body, and a long auger rod 2 is installed downward on the power head 1;

[0033] The top of the long auger rod 2 is connected with an air guide tube 4 through a rotary seal joint 3, and the air guide tube 4 is connected with an air pump 5; connect;

[0034] The lower part of the long auger rod 2 is provided with an installation cavity 7, and an electric push rod 8 is fixedly installed in the installation cavity 7, and the protruding rod 11 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com