Broken bridge heat insulation door and window

A technology for thermal insulation of broken bridges and doors and windows, which is applied in door/window protection devices, special equipment for doors/windows, windows/doors, etc., and can solve the problem of large frame, multiple indoor space resources, installation and disassembly of frame and other problems to achieve the effect of avoiding dust absorption and saving indoor space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

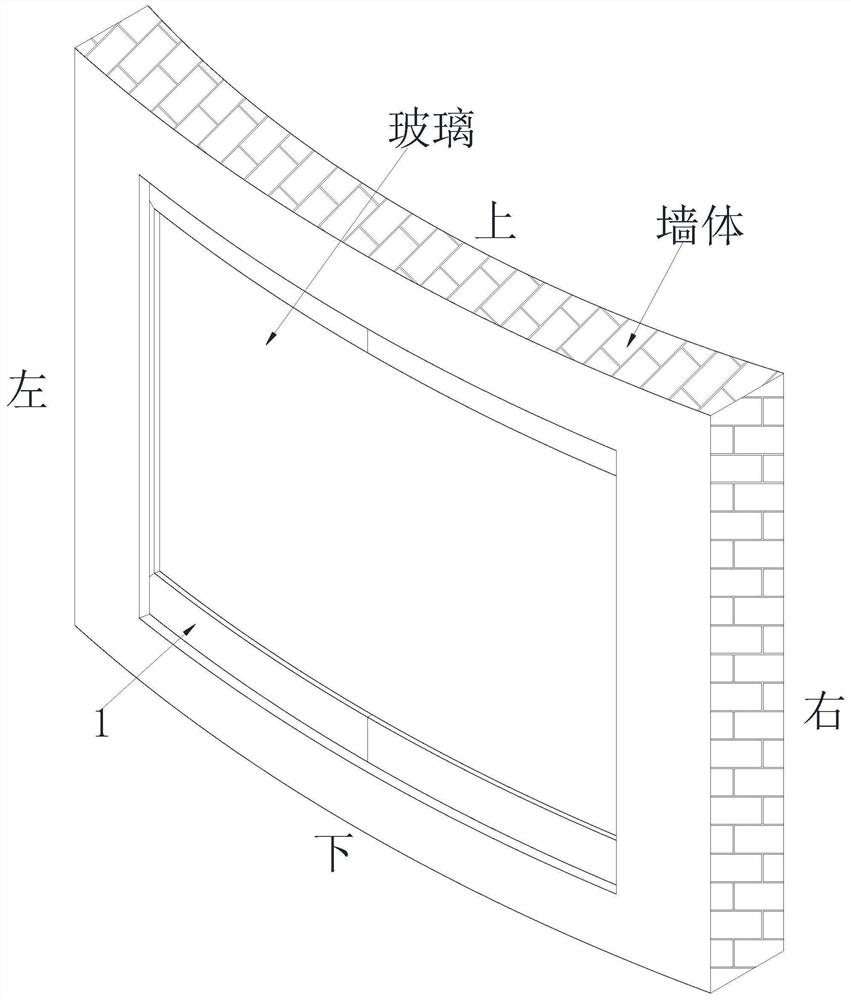

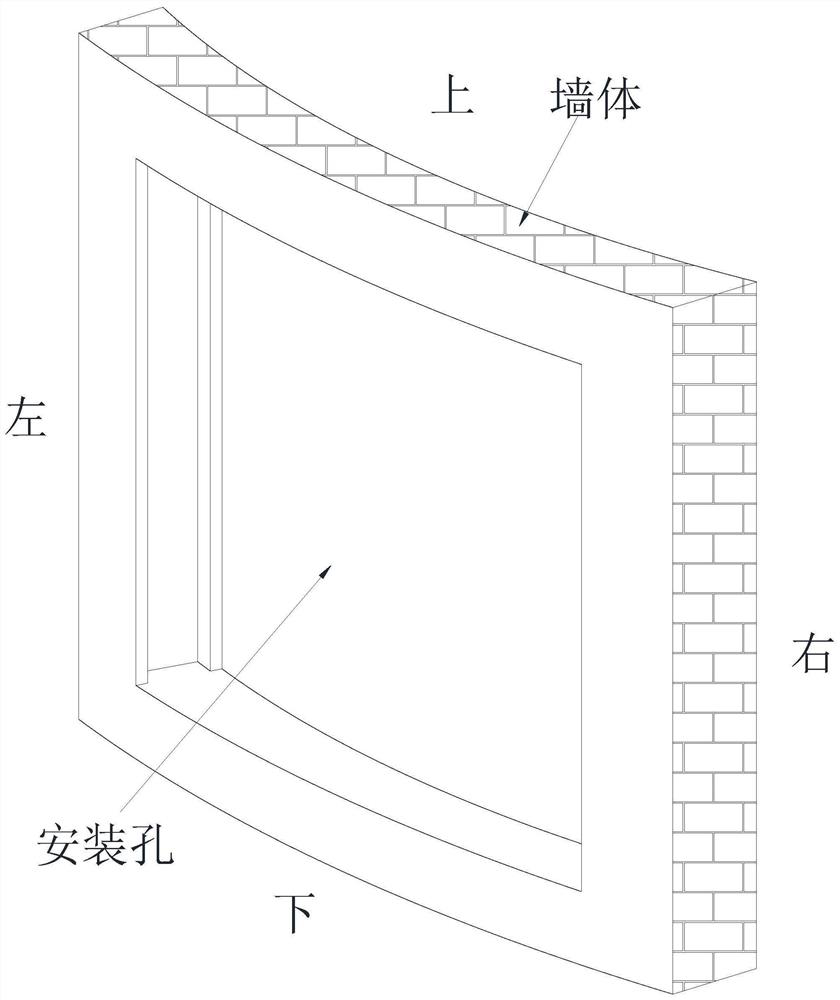

[0035] A broken bridge insulated door and window, which includes a frame body 1 and a connecting mechanism 2. There are installation holes on the wall body. The two framed bodies 1 are connected by a connecting mechanism 2 before, and two pieces of glass are installed sequentially in the two framed bodies 1; wherein:

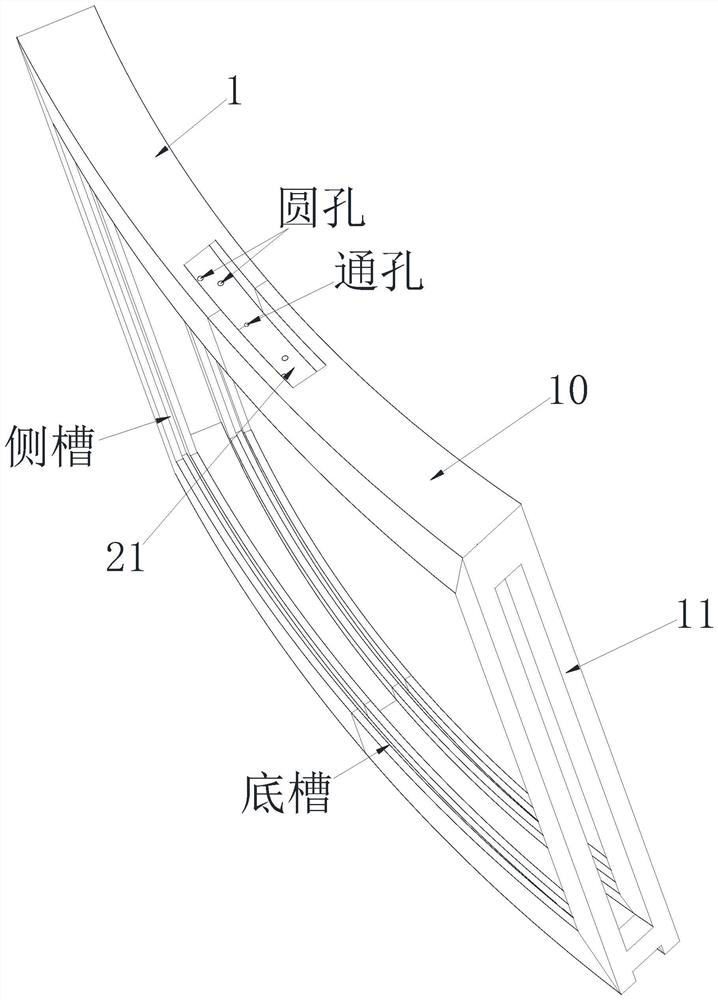

[0036]The frame body 1 is divided into two bottom frames 10 and a side frame 11, the bottom frame 10 is designed into an arc structure according to the shape of the wall, the side frame 11 is a strip structure, and the ends of the bottom frame 10 are connected to the The ends of the side frame 11 are vertically connected, the side of the bottom frame 10 away from the wall is symmetrically provided with two bottom grooves along its wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com