Processing technology of composite fabric with good anti-wrinkle effect

A composite fabric and processing technology, which is applied in fiber types, textiles, papermaking, fiber treatment, etc., can solve the problems of fabrics prone to wrinkles and poor wrinkle resistance, and achieve good wrinkle resistance, improved wrinkle resistance, and recovery performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

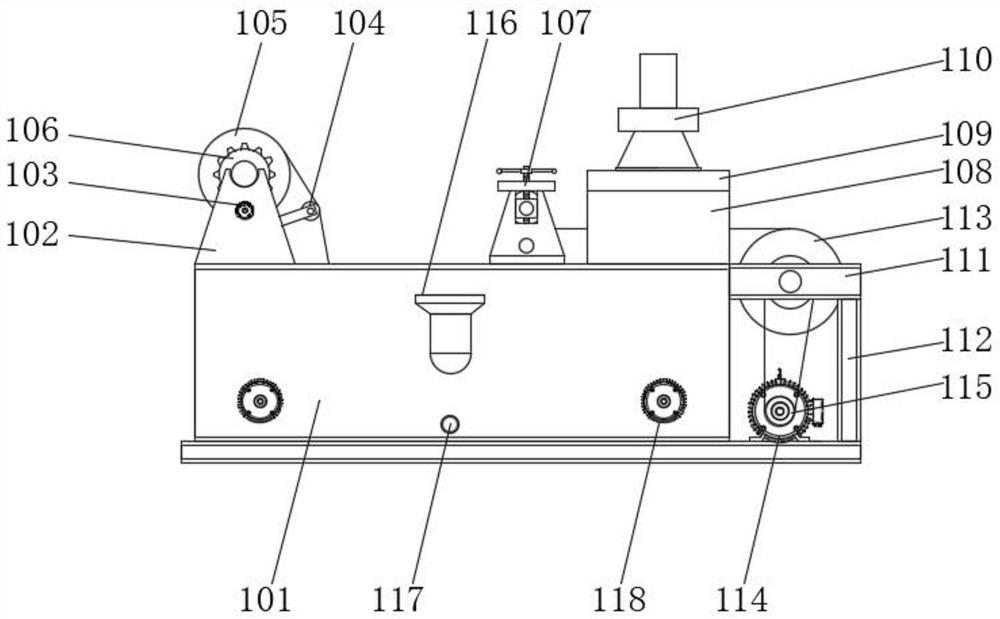

[0044] see Figure 1-7 As shown, the present embodiment is a processing technique for a composite fabric with good anti-wrinkle effect, comprising the following steps:

[0045] Step 1: Take the following raw materials by weight: 60 parts of cotton fiber, 20 parts of bamboo fiber, 20 parts of polyester fiber, 20 parts of modal fiber, and set aside:

[0046] Step 2: Mix cotton fibers, bamboo fibers, polyester fibers, and modal fibers evenly, and weave and shape them to obtain gray cloth, and perform singeing, desizing, scouring, bleaching and mercerizing on the gray cloth to obtain composite gray cloth ;

[0047] Step 3: After winding the composite gray cloth onto the unwinding cylinder 105 of the anti-wrinkle finishing equipment, place the unwinding cylinder 105 on the support plate 102, pass the unwinding cylinder 105 through one side of the first guide shaft 104, The material inlet 127, the bottom of the second guide shaft 129, the material outlet 128, between the movable r...

Embodiment 2

[0056] see Figure 1-7 As shown, the present embodiment is a processing technique for a composite fabric with good anti-wrinkle effect, comprising the following steps:

[0057] Step 1: Take the following raw materials in parts by weight: 80 parts of cotton fiber, 40 parts of bamboo fiber, 40 parts of polyester fiber, 40 parts of modal fiber, and set aside:

[0058] Step 2: Mix cotton fibers, bamboo fibers, polyester fibers, and modal fibers evenly, and weave and shape them to obtain gray cloth, and perform singeing, desizing, scouring, bleaching and mercerizing on the gray cloth to obtain composite gray cloth ;

[0059] Step 3: After winding the composite gray cloth onto the unwinding cylinder 105 of the anti-wrinkle finishing equipment, place the unwinding cylinder 105 on the support plate 102, pass the unwinding cylinder 105 through one side of the first guide shaft 104, The material inlet 127, the bottom of the second guide shaft 129, the material outlet 128, between the ...

Embodiment 3

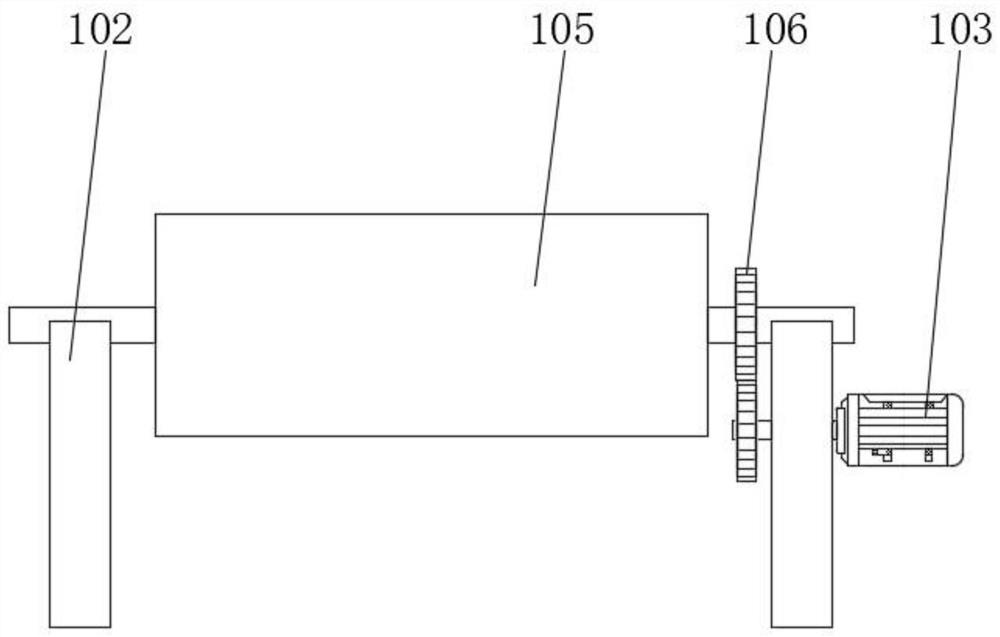

[0068] see Figure 1-7 As shown, this embodiment is an anti-wrinkle finishing equipment, including a finishing box 101, a support plate 102, a first driving motor 103, a first guide shaft 104, an unwinding drum 105, a driving gear 106, a water rolling assembly 107, and a drying box 108 , installation box 109, blower 110, installation bar 111, support bar 112, reel 113, second driving motor 114, belt pulley 115, feeding hopper 116, liquid discharge port 117, stirring motor 118, the top of described sorting box 101 Both side edge positions of one end are equipped with support plates 102, and the tops of the two support plates 102 are provided with unwinding drums 105, and a first drive motor 103 is installed on one side of one of the support plates 102. One end of the reel 105 and the output shaft of the first drive motor 103 are sleeved with a drive gear 106, and the two drive gears 106 are meshed with each other, and the other end of the top of the finishing box 101 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com