Flour bagging sealing equipment

A sealing equipment, flour technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve problems such as flour waste, low efficiency, and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

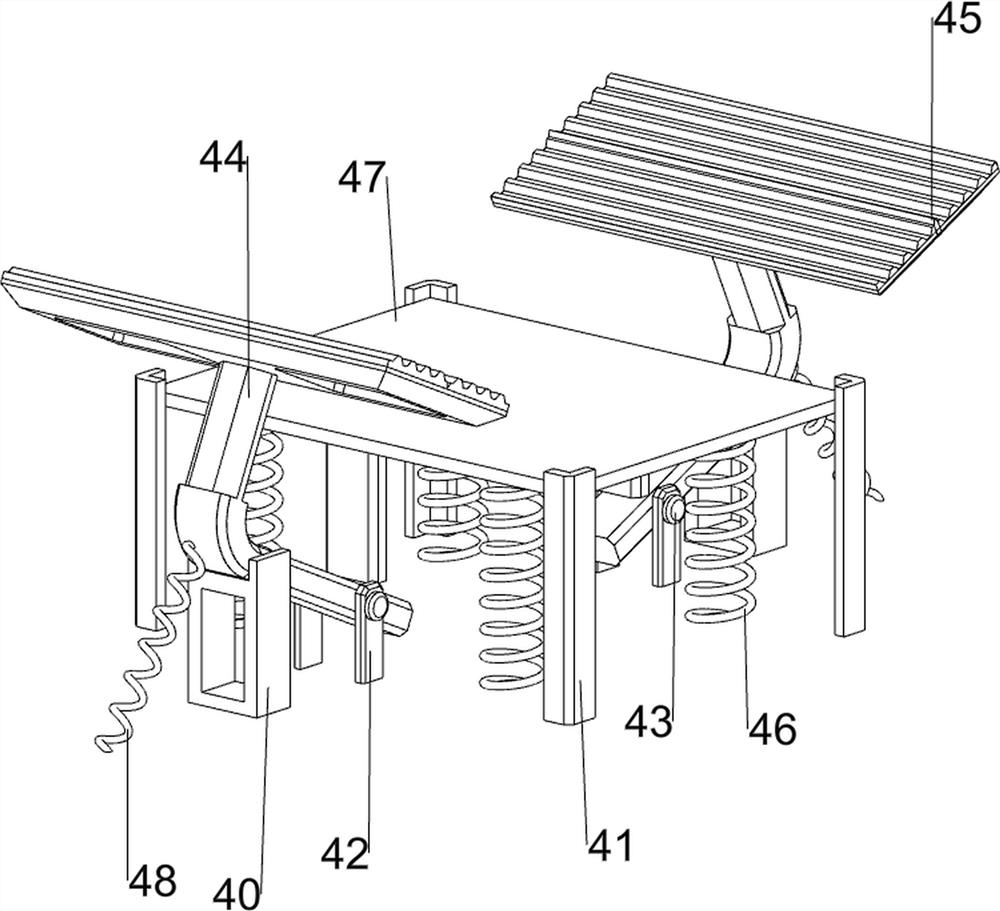

[0065] A bagging and sealing device for flour, such as Figure 1-4 As shown, it includes a base 1, a support frame 2, a feeding mechanism 3 and a sealing mechanism 4, a support frame 2 is provided on the rear side of the base 1, a feeding mechanism 3 is provided on the support frame 2, and a sealing mechanism is provided on the front side of the base 1 4.

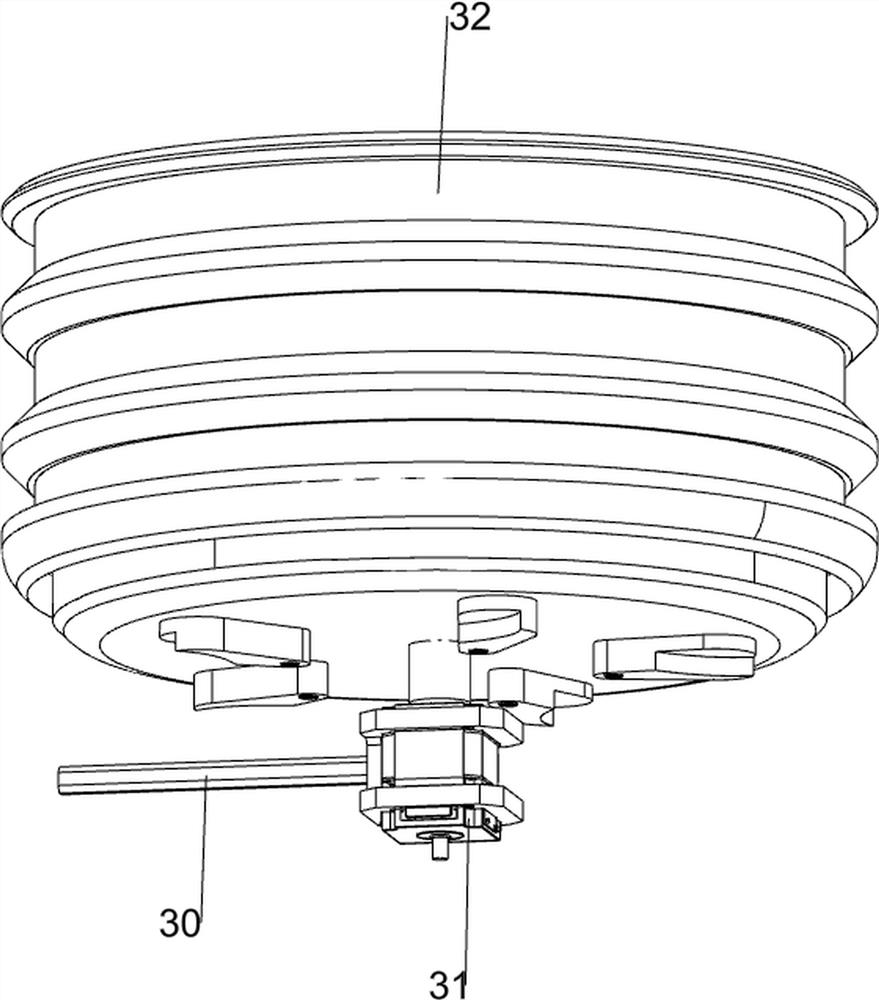

[0066] The blanking mechanism 3 includes a support rod 30, a biaxial motor 31, a storage barrel 32, a first connecting rod 33, a scroll spring 34 and a blocking block 35, and the rear side of the support frame 2 is connected with a support rod 30. A biaxial motor 31 is provided, and the top of the output shaft of the biaxial motor 31 is provided with a material storage tank 32, and the bottom of the material storage tank 32 is uniformly provided with a first connecting rod 33, and the first connecting rod 33 is connected with a blocking block 35 in a rotating manner. Small holes are evenly opened on the material storage ba...

Embodiment 2

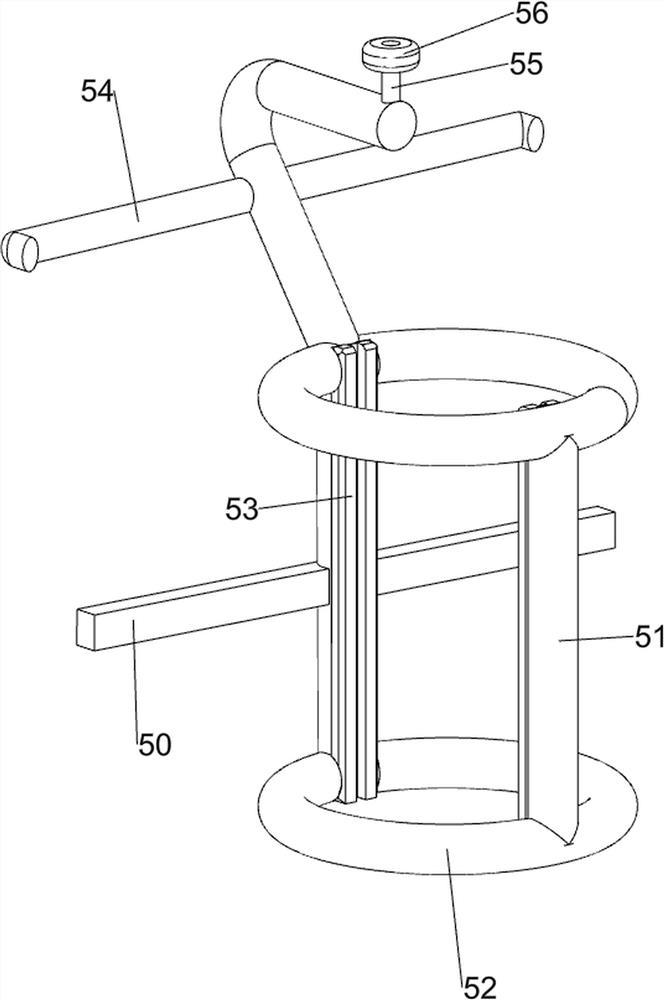

[0070] On the basis of Example 1, such as Figure 5-8 As shown, it also includes an edge banding mechanism 5, and the edge banding mechanism 5 includes a load-bearing plate 50, a connecting plate 51, a fixed ring 52, an edge bander 53, a fixed rod 54, a third connecting rod 55 and a pulley 56, and the support frame 2 The front side is provided with a load-bearing plate 50, the middle of the front side of the load-bearing plate 50 is provided with a connecting plate 51, the bottom of the connecting plate 51 is provided with a fixed ring 52, the front and rear sides of the connecting plate 51 are connected with edge banders 53, and the top and rear side of the connecting plate 51 A fixed rod 54 is provided, and a third connecting rod 55 is arranged on the front side of the top of the fixed rod 54, and a pulley 56 is connected to the top of the third connecting rod 55 in a rotational manner.

[0071] When people need to pack flour, they first pass the bags through the edge bander...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap