Manufacture device for steamed bun in catering industry

A technology for manufacturing equipment and the catering industry, which is applied in dough forming and cutting equipment, applications, food science, etc., and can solve problems such as cumbersome steps, time-consuming and labor-intensive tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

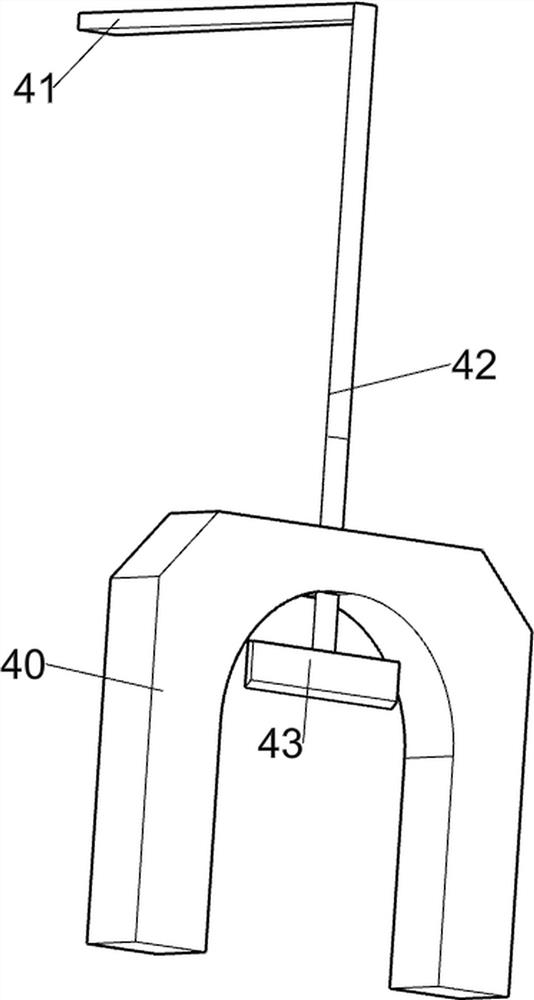

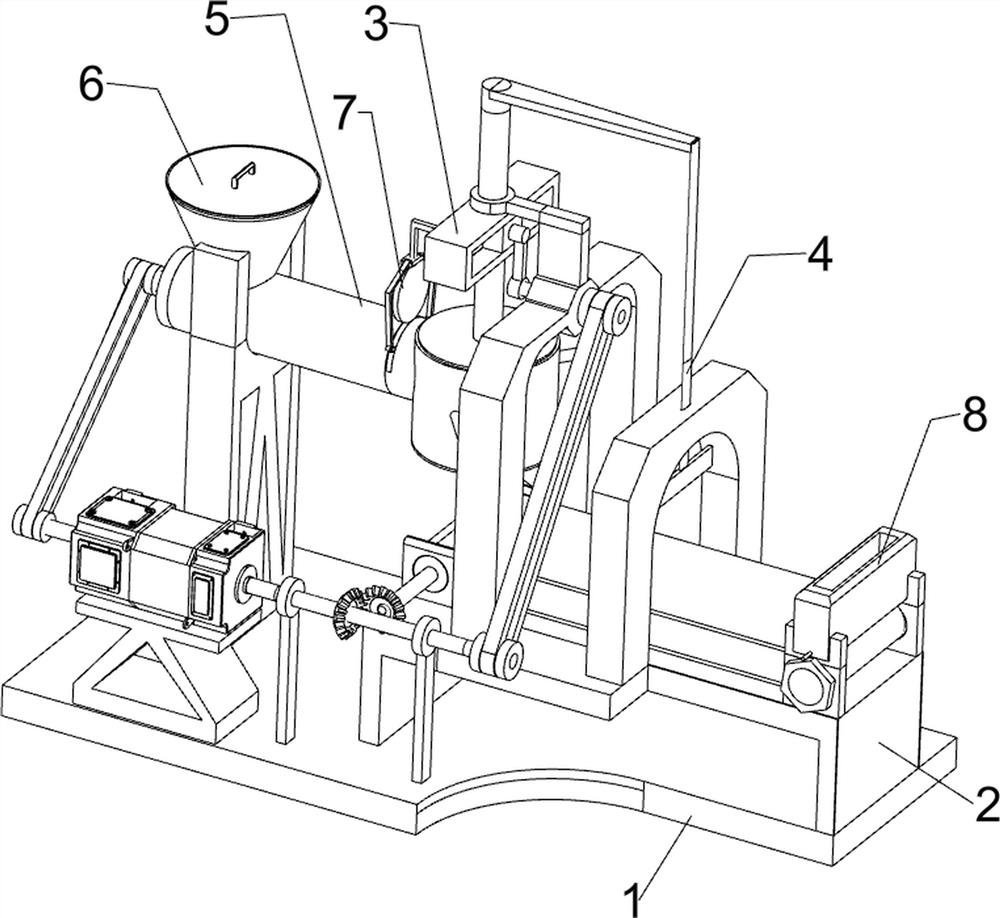

[0063] A steamed bun manufacturing equipment for catering industry, such as Figure 1-3 As shown, it includes a load-bearing plate 1, a load-bearing table 2, a reciprocating mechanism 3 and a cutting mechanism 4, a load-bearing table 2 is provided on the right side of the load-bearing plate 1, a reciprocating mechanism 3 is provided between the load-bearing plate 1 and the load-bearing table 2, and the load-bearing table 2 There is a cutting mechanism 4 on it.

[0064] The reciprocating mechanism 3 includes a support seat 30, a bearing seat 31, a support column 32, a servo motor 33, a rotating shaft 34, a first transmission assembly 35, a crank 36, a fixed frame 37, a fixed slider 38, a transmission assembly 39, and a bevel gear assembly 310 And the lower material barrel 311, the left front side of the load bearing plate 1 is provided with a support seat 30, the support base 30 is provided with a servo motor 33, and the front portion of the load bearing plate 1 is provided wit...

Embodiment 2

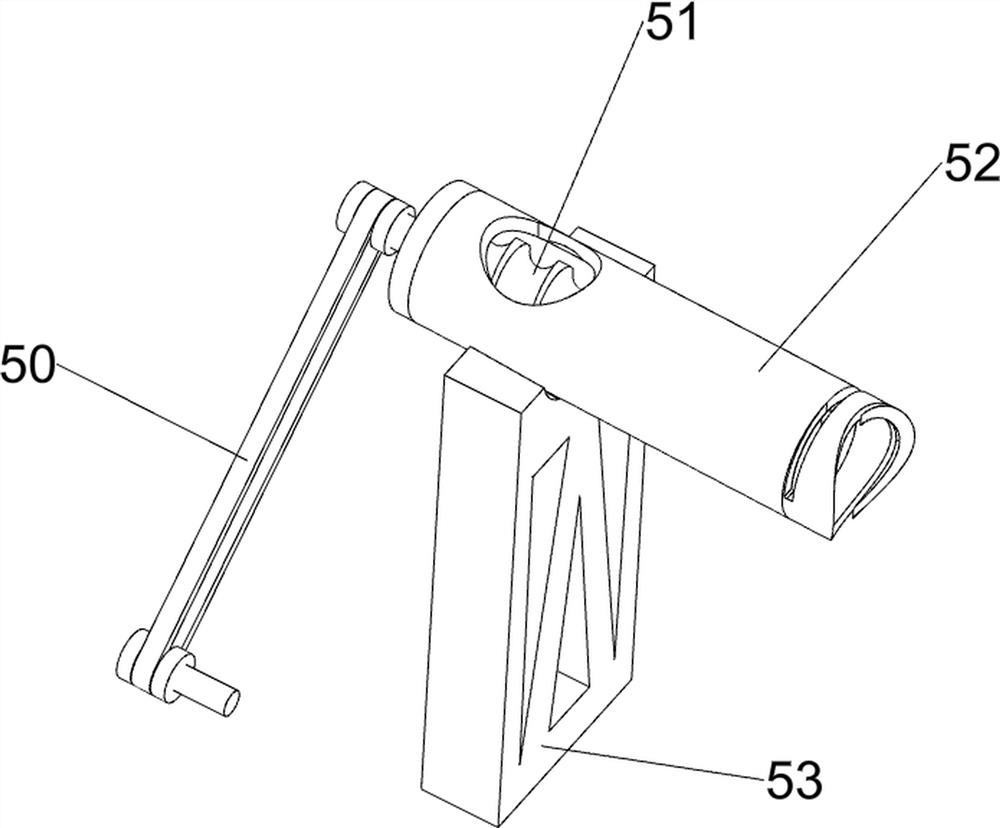

[0068] On the basis of Example 1, such as Figure 4-8 As shown, a material stirring mechanism 5 is also included, and the material stirring mechanism 5 includes a second transmission assembly 50, an agitator 51, a storage tank 52 and a base 53, and the left part of the bearing plate 1 is provided with a base 53, and the base 53 is connected with the blanking A storage barrel 52 is connected between the buckets 311, and an agitator 51 is rotatably connected in the storage barrel 52, and a second transmission assembly 50 is connected between the left side of the agitator 51 and the output shaft on the left side of the servo motor 33.

[0069] People can pour water and flour into the storage barrel 52, and the output shaft of the servo motor 33 rotates to drive the second transmission assembly 50 and the agitator 51 to rotate, so that the agitator 51 continuously stirs the water and flour, so that the dough is stirred to the right Convey so that the material dough is fixed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com