Anti-explosion semi-automatic nail-free glue filling machine

A technology of nail-free glue and packaging machine, which is applied in the direction of packaging, etc., can solve the problems of nail-free glue that is difficult to clean, nail-free glue leaking to equipment, and stability of nail-free glue, etc., to achieve semi-automatic processing and production and improve production quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

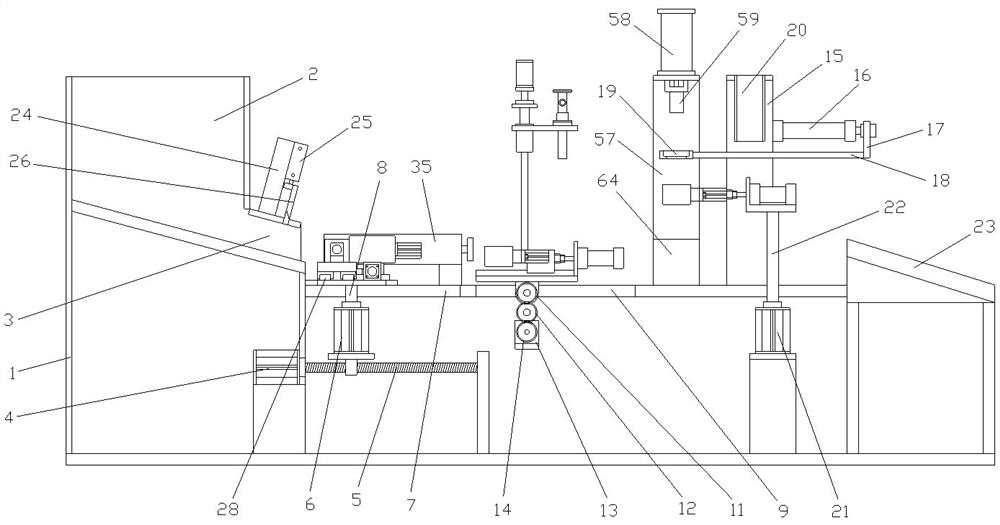

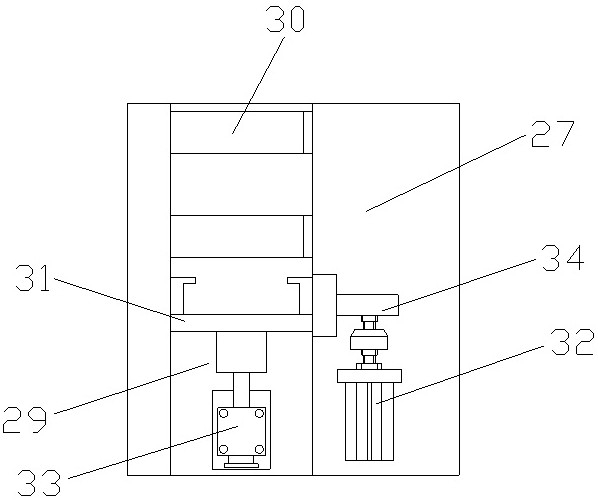

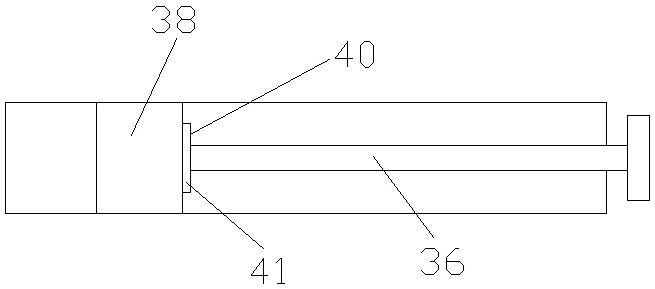

[0025] Such as Figure 1~8As shown in combination, the explosion-proof semi-automatic nail-free glue dispensing machine includes a machine base 1, a bottle storage bin 2 is arranged on one side of the machine base 1, and a discharge port 3 is arranged on one side of the bottle storage bin 2, The top of the discharge port 3 is provided with a limit mechanism, the base 1 below the bottle storage bin 2 is provided with a first motor 4, the driving end of the first motor 4 is provided with a lead screw 5, the The lead screw nut of the lead screw 5 is provided with a second motor 6, the surface of the base 1 above the second motor 6 is provided with a chute 7, and the driving end of the second motor 6 is provided with a first connecting rod 8 , the first connecting rod 8 extends to the outside of the chute 7 and is connected with a first feeding mechanism, the base 1 outside the first feeding mechanism is provided with a bottom cover feeding mechanism, and the bottom cover feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com