Film laminating machine for pre-coating film production

A pre-coating film and laminating machine technology, which is applied to layered products, lamination devices, lamination, etc., can solve the problems of uneven heating, increased power consumption, etc., to prevent heat transfer, increase power consumption, The effect of accelerating heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

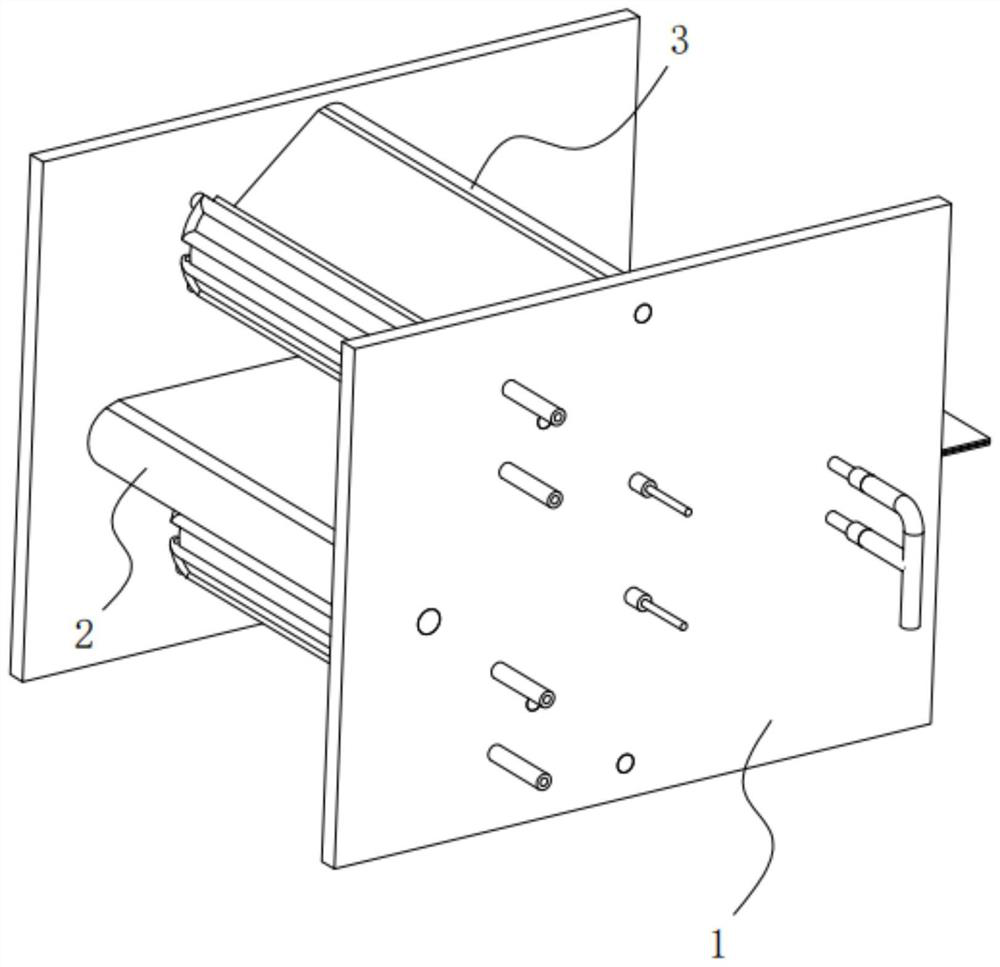

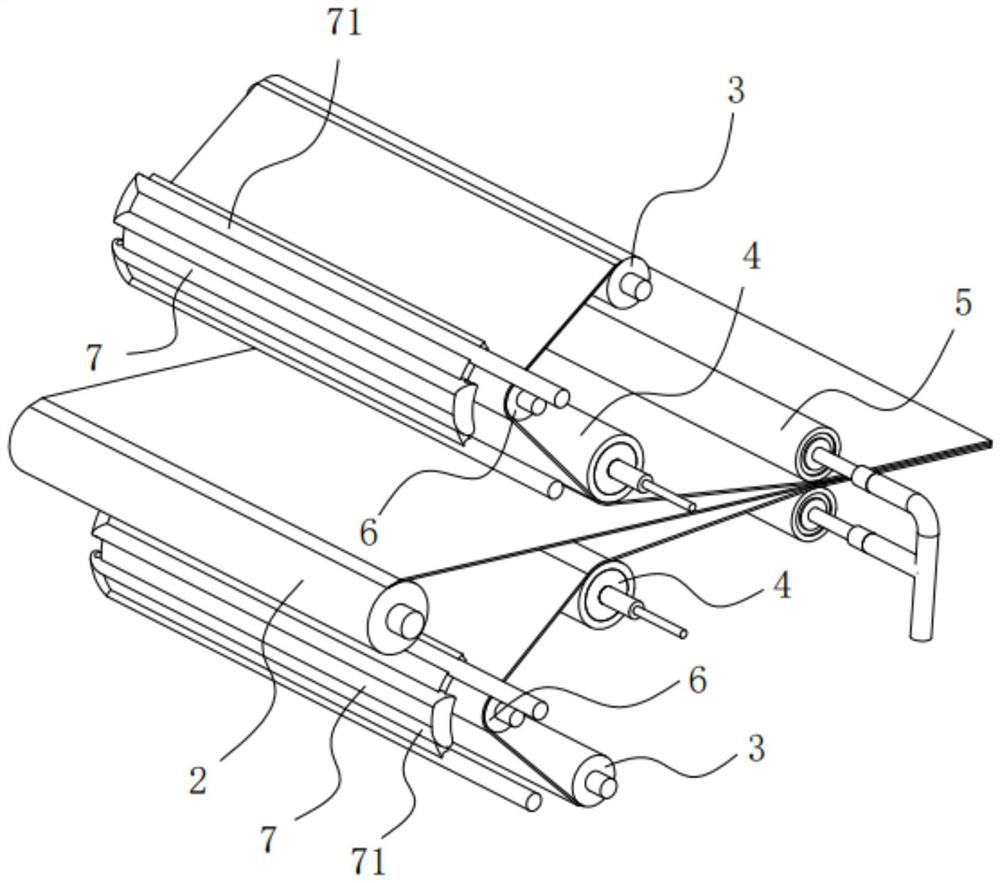

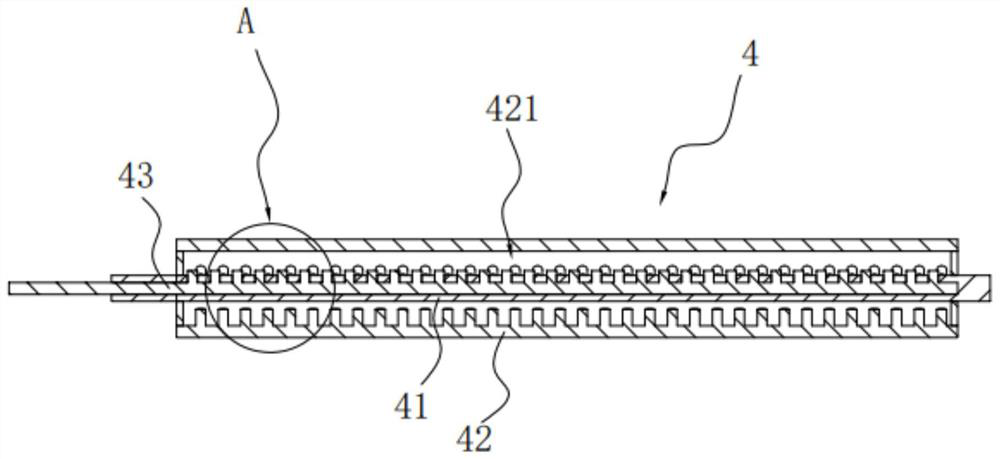

[0049] Embodiment: a kind of laminating machine for precoating film production, see attached figure 1 And attached figure 2 , including a frame 1 supported on the ground, a coating roller 2 rotatably connected to the frame 1, a pre-coating film roller 3 rotatably connected to the frame 1, a heating pipe rotatably connected to the frame 1 and a rotating Two extrusion rollers 5 connected on the frame 1. Specifically, the paper to be coated is wound on the coating roll 2, and a pre-coating film is wound on the outside of the pre-coating film roll 3, and the pre-coating film is pasted around the heating roll 4 and then bonded to the paper. The precoat film is attached to the outside of the heating roller 4 when it is wound around the heating roller 4 .

[0050] When carrying out paper coating, the paper to be coated is wound on the outside of the coating roll 2, the pre-coating film is wound on the outside of the pre-coating film roll 3, and then the paper and the pre-coating f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com