Precision mold for production and processing

A technology of precision molds and boxes, applied in the direction of manufacturing tools, material forming presses, presses, etc., can solve the problems that affect the production and processing work effect and work accuracy, and the mold is difficult to maintain stability and high precision. Work effect, improved precision, uniform and effective processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

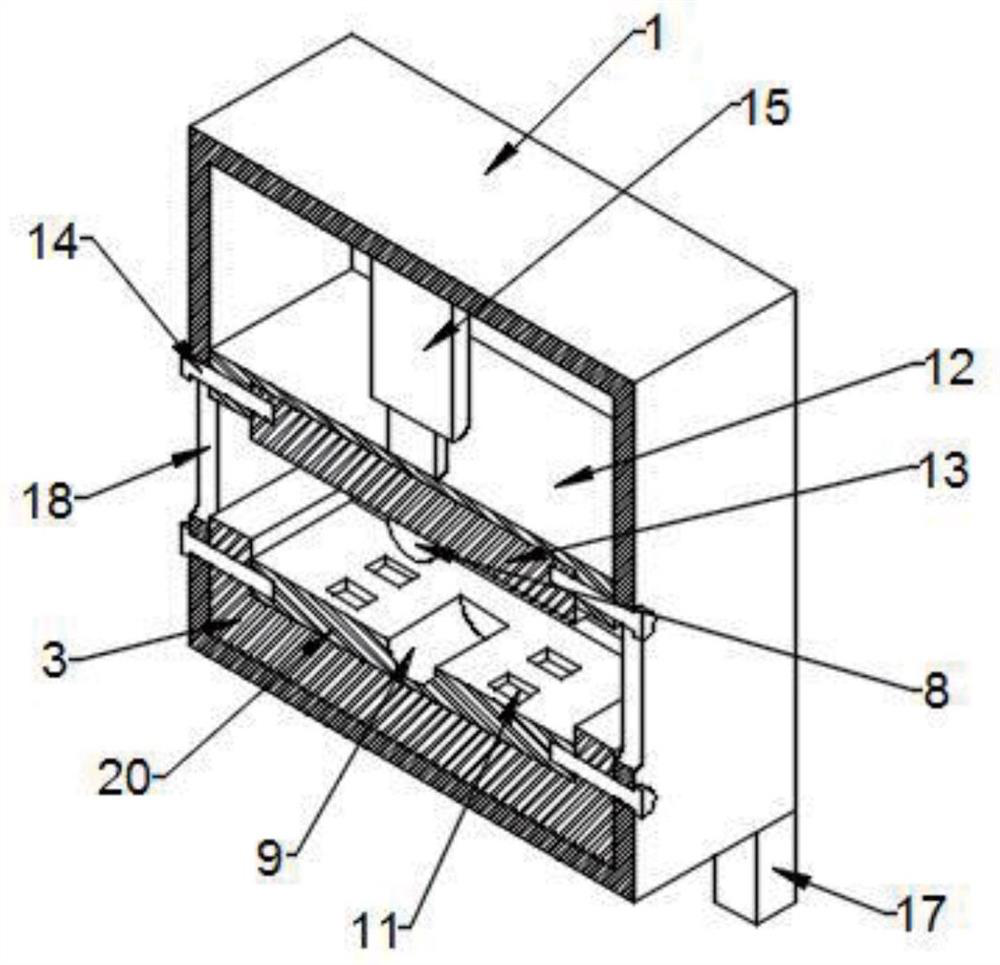

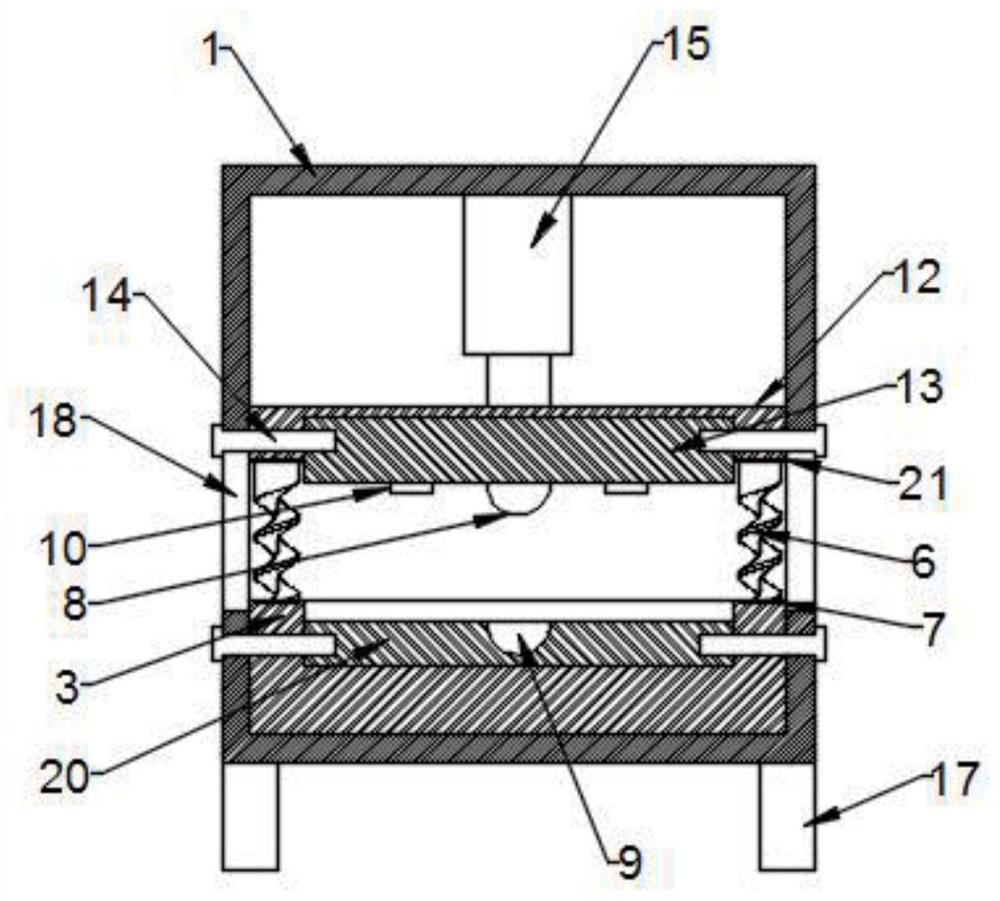

[0021] see Figure 1~5 , a precision mold for production and processing, comprising a box body 1, the bottom of the box body 1 is fixedly installed with a horizontal mounting seat 3, and the middle part of the upper surface of the mounting seat 3 is provided with a first indwelling groove 4, and the first indwelling groove 4 A base 20 is provided inside, a horizontal press block 12 is provided above the mounting base 3, a second indwelling groove 5 is provided in the middle of the lower surface of the press block 12, and a horizontal pressing plate 13 is provided in the second indwelling groove 5. A bolt 14 is inserted between the middle part of the outer surface of the two ends of the mounting seat 3 and the base 20, and a bolt 14 is also inserted between the middle part of the outer surface of the two ends of the pressure block 12 and the pressing plate 13, and the box body 1 has two The middle part of the end outer surface is located at the lower side of the upper bolt 14 a...

Embodiment 2

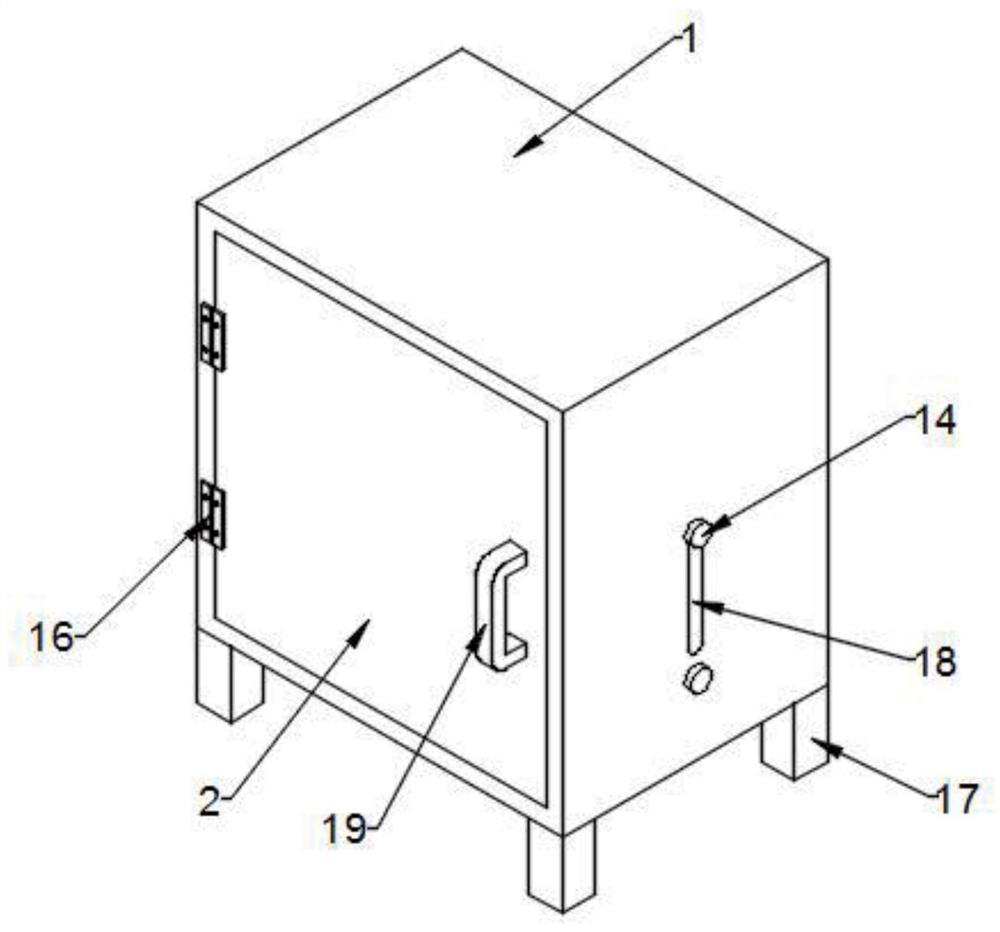

[0023] see Figure 1~5 , in the case that other parts are the same as in Embodiment 1, the difference between this embodiment and Embodiment 1 is that a horizontal arc-shaped groove 9 is opened in the middle of the upper surface of the base 20, and the upper surface of the base 20 is located in an arc-shaped Both sides of the groove 9 are evenly spaced with a number of square grooves 11, and the middle part of the lower surface of the pressing plate 13 is fixedly equipped with an arc-shaped block 8 matching the arc-shaped groove 9, and the lower surface of the pressing plate 13 is installed at intervals on both sides of the arc-shaped block 8. There are a number of square blocks 10 matching the square grooves 11. The front side of the box body 1 is in an open state, and a box door 2 is provided at the opening position of the front side of the box body 1. One end of the outer surface of the box door 2 is connected to the outer surface of the box body 1. A hinge 16 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com