High-stability adjustable electric industrial brush

A high-stability, adjustable technology, applied in cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., can solve problems such as inability to flexibly handle irregular objects and inconvenient adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

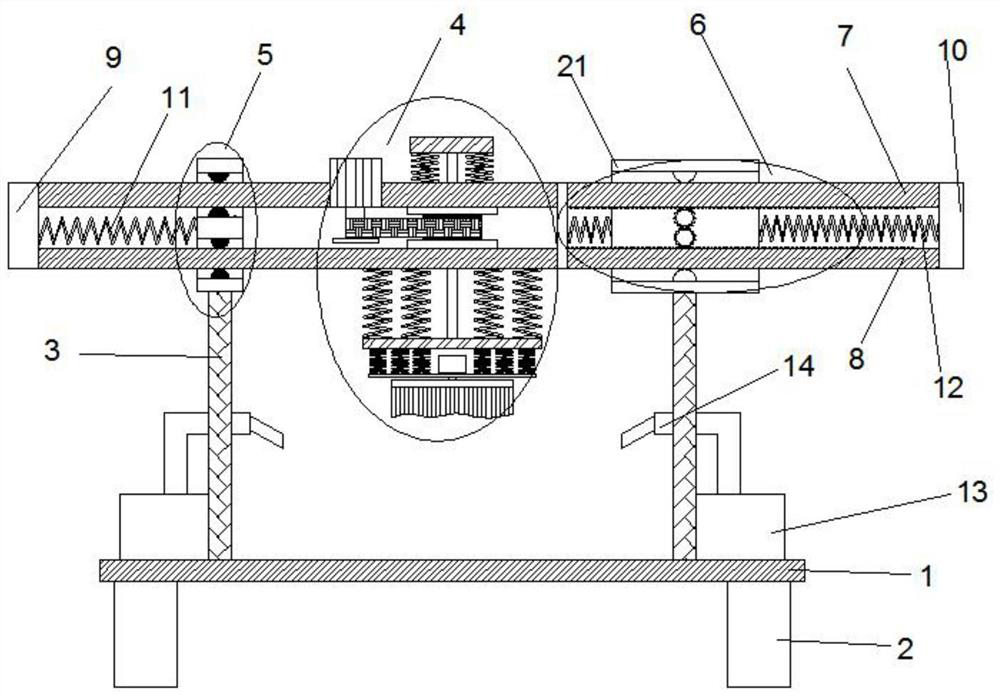

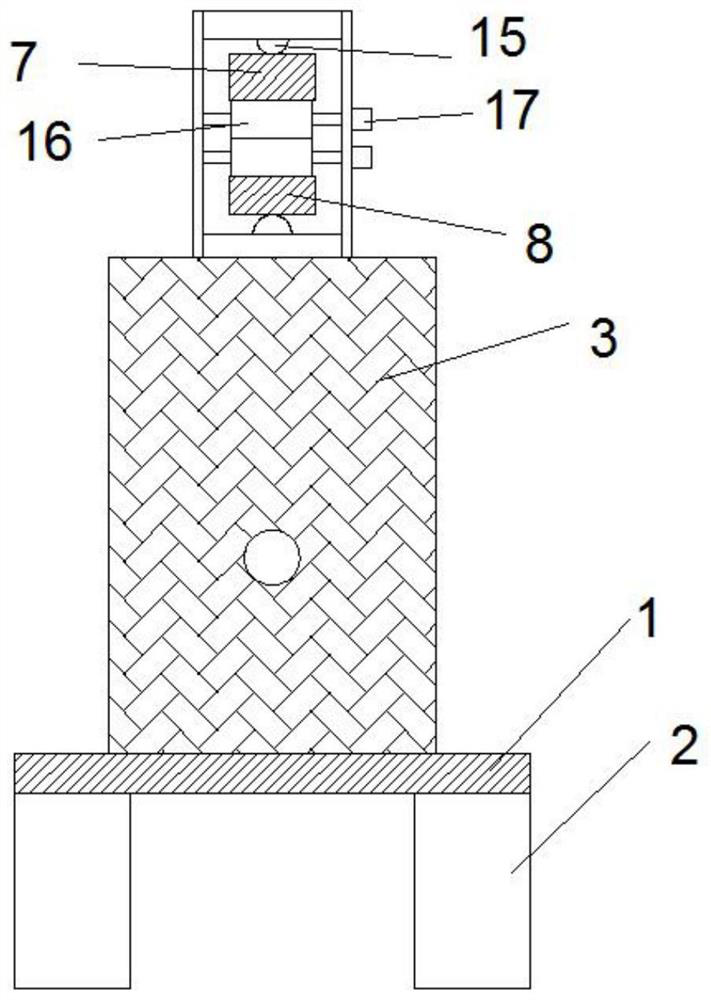

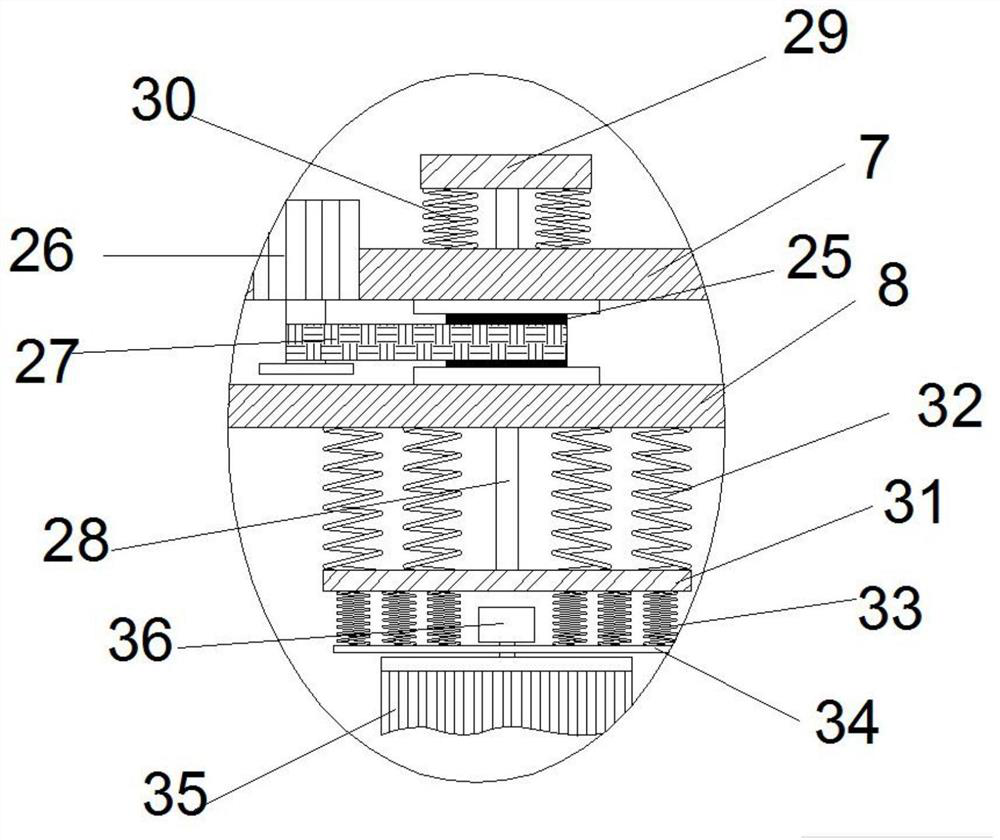

[0028] refer to Figure 1-5 , a high-stability adjustable electric industrial brush, including a workbench 1, support legs 2 arranged in a quadrangular array at the lower end of the workbench 1, side plates 3 arranged symmetrically on both sides of the upper end of the workbench 1, and a lift connected above the side plates Brush mechanism 4, first moving mechanism 5 and second moving mechanism 6, described lifting brush mechanism 4 is arranged between side plates 3, comprises upper moving rod 7, lower moving rod 8, rotating screw rod 28 and rotating brush 35, so A rotating block 25 is arranged between the upper moving rod 7 and the lower moving rod 8, and the rotating block 25 is respectively connected to the upper moving rod 7 and the lower moving rod 8 in rotation, and the upper moving rod 7 is provided with a second motor 26, and the first Two motor 26 output shafts are connected with rotating block 25 by rotating belt 27, described rotating screw rod 28 passes through upp...

Embodiment 2

[0035] Such as Figure 1-4 and Figure 6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the upper and lower ends on the right side of the upper moving rod 7 and the lower moving rod 8 are provided with moving teeth 18, and the upper moving rod 7 and the lower moving rod 8 The top and bottom of the right fixed block 21 are provided with rotating gears 16 meshed with moving teeth 18 . The sensitivity of the left and right movement of the upper moving rod 7 and the lower moving rod 8 is effectively improved.

Embodiment 3

[0037] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inside of the side plate 3 is rotatably connected to the spray port 14, and the spray port 14 communicates with the fixed water tank 13 on the upper end of the workbench 1 through a pipe. In order to facilitate cleaning and scrubbing of objects.

[0038] Working principle: when using, first fix the object to be processed on the workbench 1, and start the first motor 17 and the second motor 26 according to the type and height of the object, so that the rotating brush 35 moves up and down, left and right, and sticks to the surface of the object Then start the third motor 36 to process the surface of the object, and at the same time, the spray port 14 can be opened to spray the object during the processing, so as to efficiently process the surface of the object.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com