Fixing device for ball workpiece machining

A technology for fixing devices and workpieces, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of workpiece damage, increased difficulty, easy sliding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

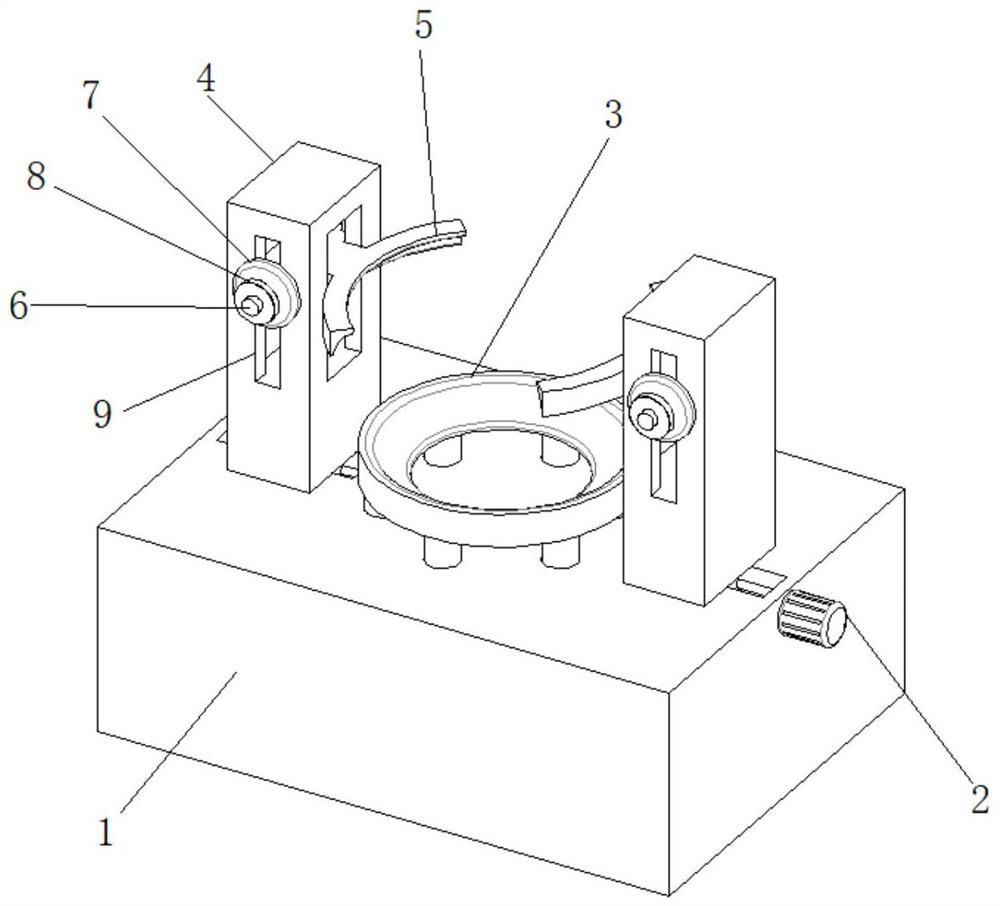

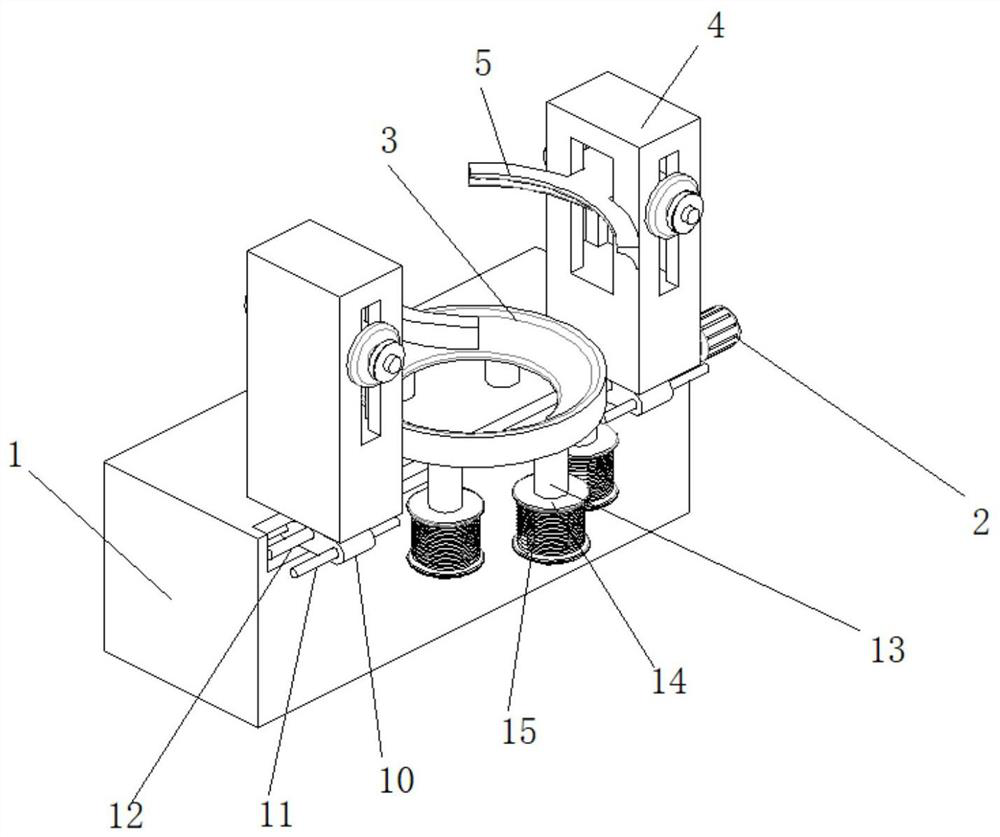

[0031] like Figure 1-4 As shown: the present invention provides a processing and fixing device for spherical workpieces. The device for processing and fixing spherical workpieces includes a base 1, and two ends of the base 1 are respectively slidably provided with supporting seats 4, and the supporting seats 4 is movably provided with an arc-shaped clamp ring 5, the surface of the support base 4 is also provided with a support ring 3 between the two support bases 4, and a cavity is formed inside the support base 4 , the upper end surface of the base 1 is formed with a chute communicating with the cavity, a screw lever 12 is rotatably arranged in the cavity, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com