Intelligent welding equipment and intelligent welding method for metal materials

A technology for metal materials and welding equipment, applied in the field of intelligent welding equipment for metal materials, can solve the problems of reducing the convenience and intelligence of welding, unable to realize circular welding, unable to realize automatic adjustment, etc., to improve welding convenience and intelligence, Improve welding accuracy and improve cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

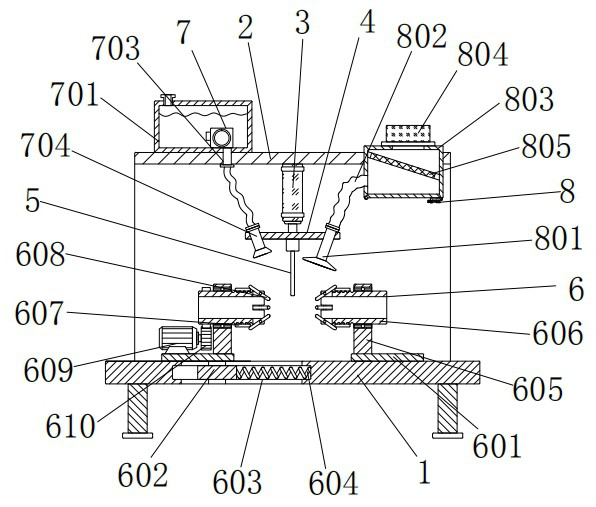

[0034] An intelligent welding equipment for metal materials, comprising a bottom platform 1, a frame 2 is fixedly connected to the top of the bottom platform 1, a cylinder 3 is fixedly connected to the top of the inner wall of the frame 2, a horizontal plate 4 is fixedly connected to the telescopic end of the cylinder 3, and a horizontal plate 4 is fixedly connected to the The center of the bottom of the plate 4 is equipped with a welding torch 5, and the top of the base 1 is provided with a clamping assembly 6, which includes a support plate 601, a slide block 602, a chute 603, a spring 604, a riser 605, a casing 606, Collar 607, clamping rod 608, motor 609 and gear 610, the bottom of the support plate 601 on the right side is fixedly connected with the top right side of the base 1, and the bottom of the support plate 601 on the left side is fixedly connected with a slide block 602, the slide block The outer wall gap of 602 is fitted with a chute 603, the slider 602 and the ch...

Embodiment 2

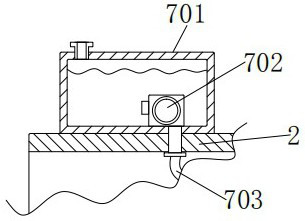

[0036] As an option, see figure 1 with 2 , metal material intelligent welding equipment, the left side of the frame 2 is provided with a cooling assembly 7, the cooling assembly 7 includes a water tank 701, a water pump 702, a plastic hose 703 and a nozzle 704, and the bottom of the water tank 701 is fixedly connected to the top left end of the frame 2 A water pump 702 is installed at the bottom of the inner wall of the water tank 701. The model of the water pump 702 is L0. The water outlet of the water pump 702 is respectively connected with the bottom of the water tank 701 and the left side of the top of the frame 2. The water outlet of the water pump 702 is connected with a plastic hose. 703 , the end of the plastic hose 703 communicates with a nozzle 704 , and the outer wall of the nozzle 704 penetrates and is fixed to the inner left side of the horizontal plate 4 .

[0037] The solution in this embodiment can be selectively used in combination with the solutions in other...

Embodiment 3

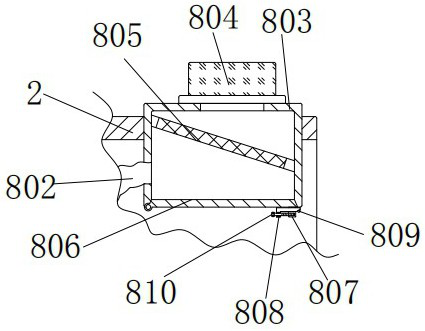

[0039] As an option, see figure 1 , 3And 4, metal material intelligent welding equipment, the right side of the frame 2 is provided with an exhaust gas treatment assembly 8, and the exhaust gas treatment assembly 8 includes an air collecting pipe 801, a rubber hose 802, a square box 803, an exhaust fan 804, a filter screen 805, and a bottom plate 806 , bump 807, curved rod 808, clamping rod 809 and screw rod 810, the outer wall of air collecting pipe 801 penetrates and is fixedly connected to the right end of horizontal plate 4, and the top of air collecting pipe 801 communicates with the left end of square box 803 through rubber hose 802, The square box 803 runs through and is fixedly connected to the top right side of the frame 2, and the air collecting pipe 801 and the water pipe 704 are arranged correspondingly to the position of the welding torch 5, and the air collecting pipe 801 and the water pipe 704 are all obliquely inwardly pointing to the bottom of the welding torc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com