High-frequency electromagnetic induction focusing welding device

A high-frequency electromagnetic and welding device technology, applied in high-frequency current welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of substrate warpage, large size, excessive thermal stress of laser reflow welding, etc., and achieve magnetic flux Enhanced density, reduced substrate warpage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

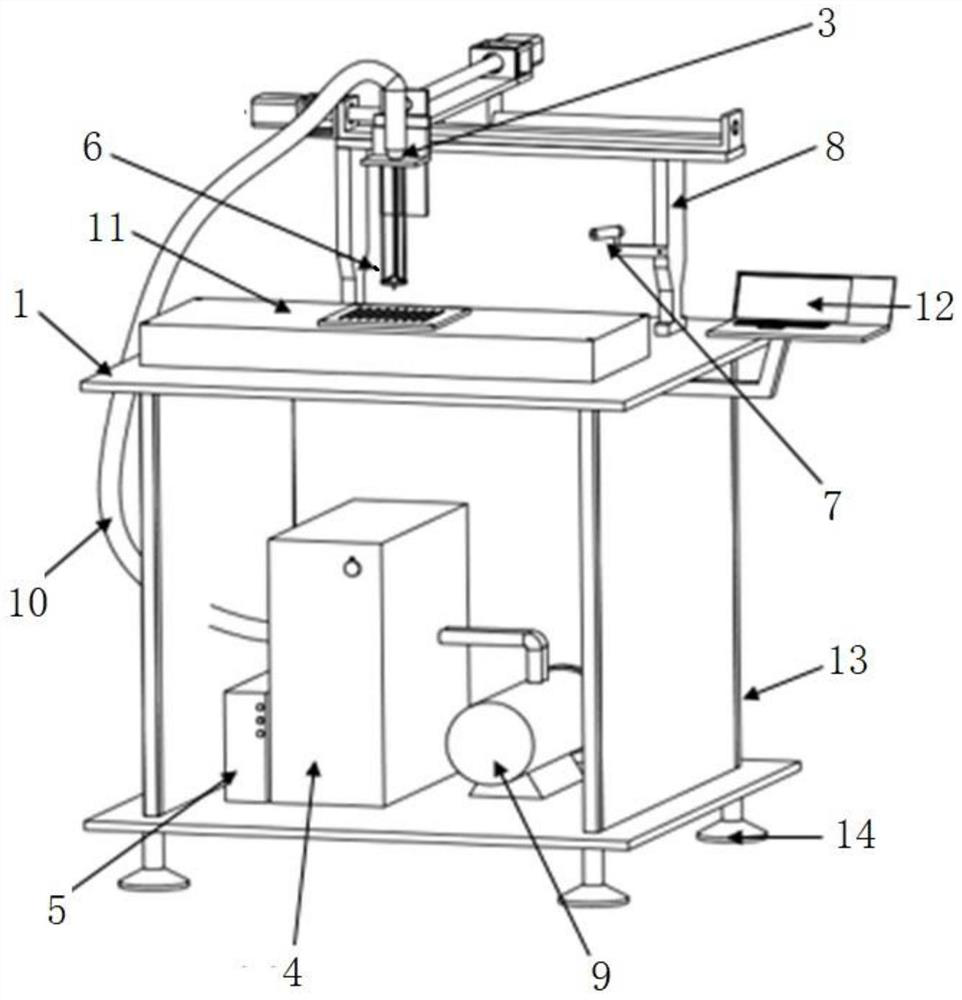

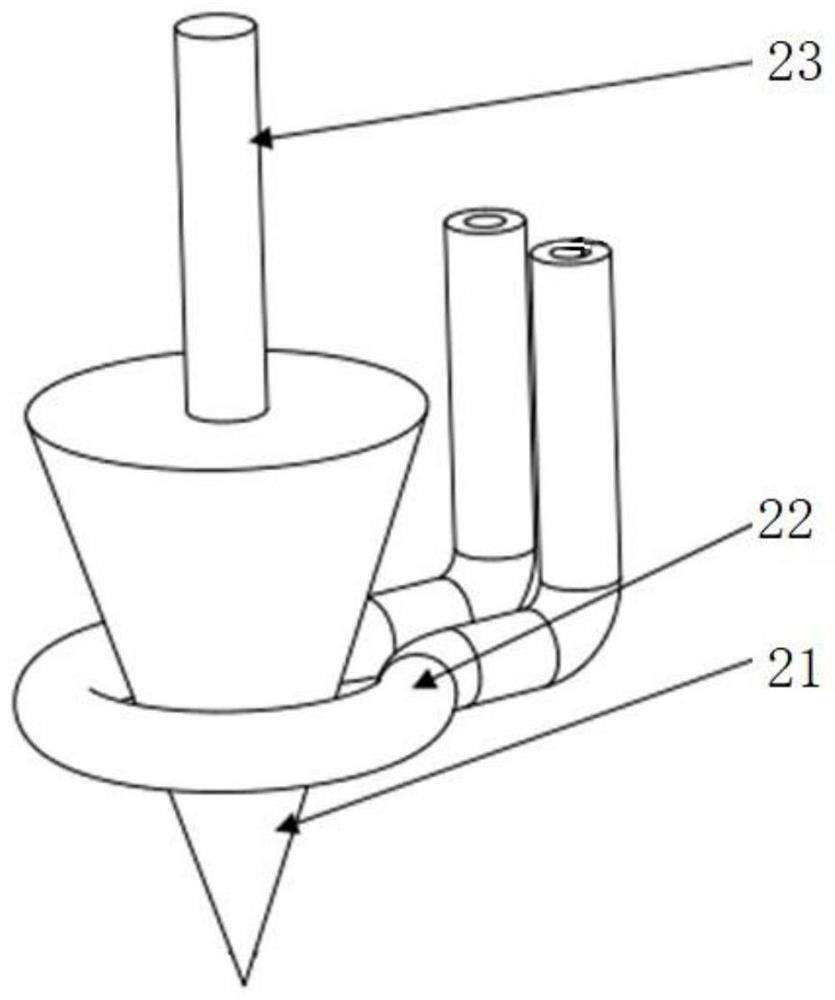

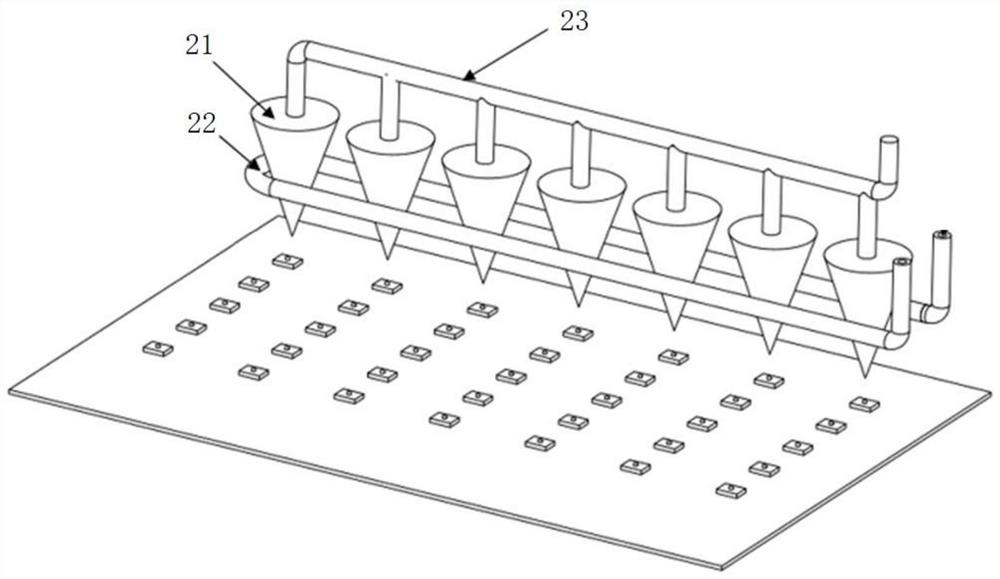

[0019] like Figure 1 to Figure 3 As shown, the present invention discloses a high-frequency electromagnetic induction focusing welding device, which includes a welding platform 1, a high-frequency focusing induction heating head arranged at the upper end of the welding platform 1, and a welding head arranged at the lower end of the welding platform 1 and connected to the welding platform 1 A high-frequency electromagnetic generator connected to a high-frequency focusing induction heating head, a three-dimensional motion mechanism 8 for driving the high-frequency electromagnetic generator to perform three-dimensional motion is provided above the welding platform 1, and the high-frequency focusing electromagnetic induction heating head includes Several conical ferrites 21 and hollow induction coils 22 wound around the periphery of the several conical ferrites 21, when there are multiple conical ferrites 21, batch welding can be performed at the same time, and the welding effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com