A maintenance-friendly bending device for the production of aerospace parts

A bending device and parts technology, applied in the field of bending devices for aviation parts production, can solve the problems of plate wear, poor positioning effect of storage plate, poor flexibility, etc., and achieve the effect of reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

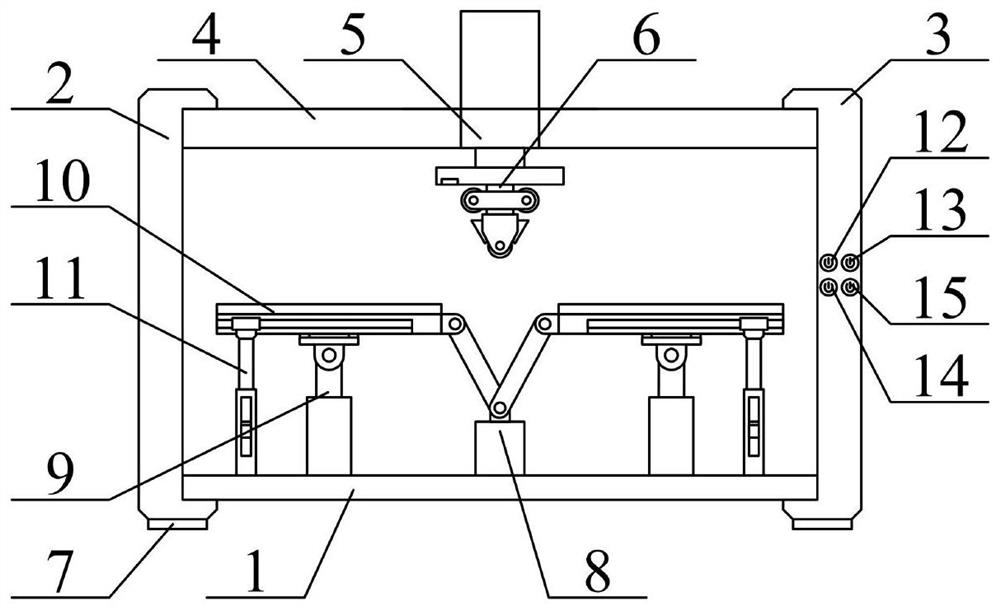

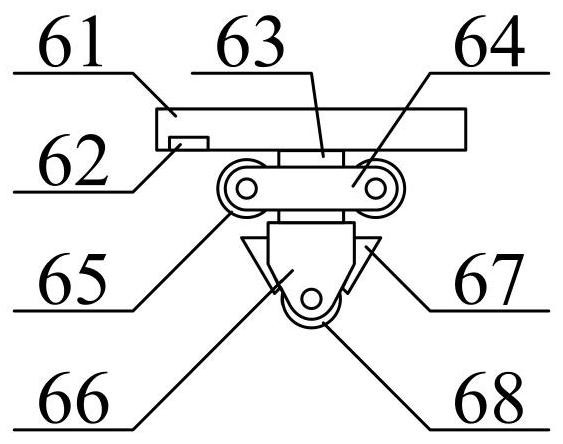

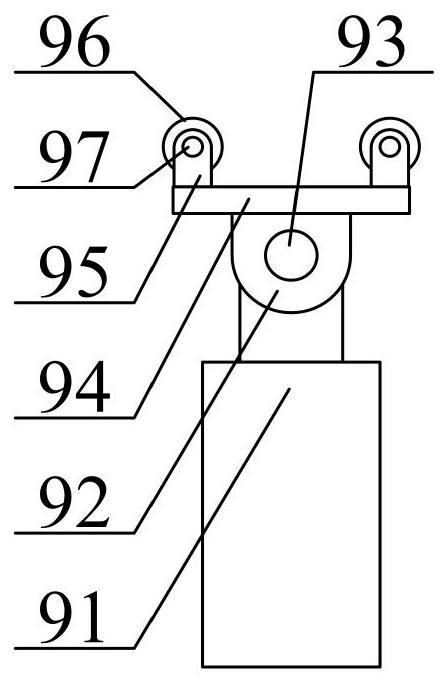

[0039] as attached figure 1 and attached Figure 5 shown

[0040]The present invention provides a bending device for the production of aviation parts that is easy to maintain, comprising a lateral bottom plate 1 , a left fixing frame 2 , a right fixing frame 3 , a lateral top frame 4 , an upper cylinder 5 , and an upper top tightening frame structure 6 . , anti-skid bottom plate 7, bottom fixing frame 8, lifting guide frame structure 9, adjustable carrying frame structure 10, side positioning frame structure 11, upper side up switch 12, upper side down switch 13, lower side up switch 14 and down Side down switch 15, the lateral top frame 4 is arranged on the inner upper part of the lateral bottom plate 1; the upper cylinder 5 bolts are installed on the middle and upper part of the lateral top frame 4; the upper top tightening frame structure 6 Installed on the lower part of the upper cylinder 5; the bottom fixing frame 8 bolts are installed on the middle and upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com