Cleaning device with temperature compensation function for chemical equipment

A technology for temperature compensation and chemical equipment, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of inconvenient cleaning and fixing of chemical tanks, achieve convenient parameter adjustment, improve stability, improve The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

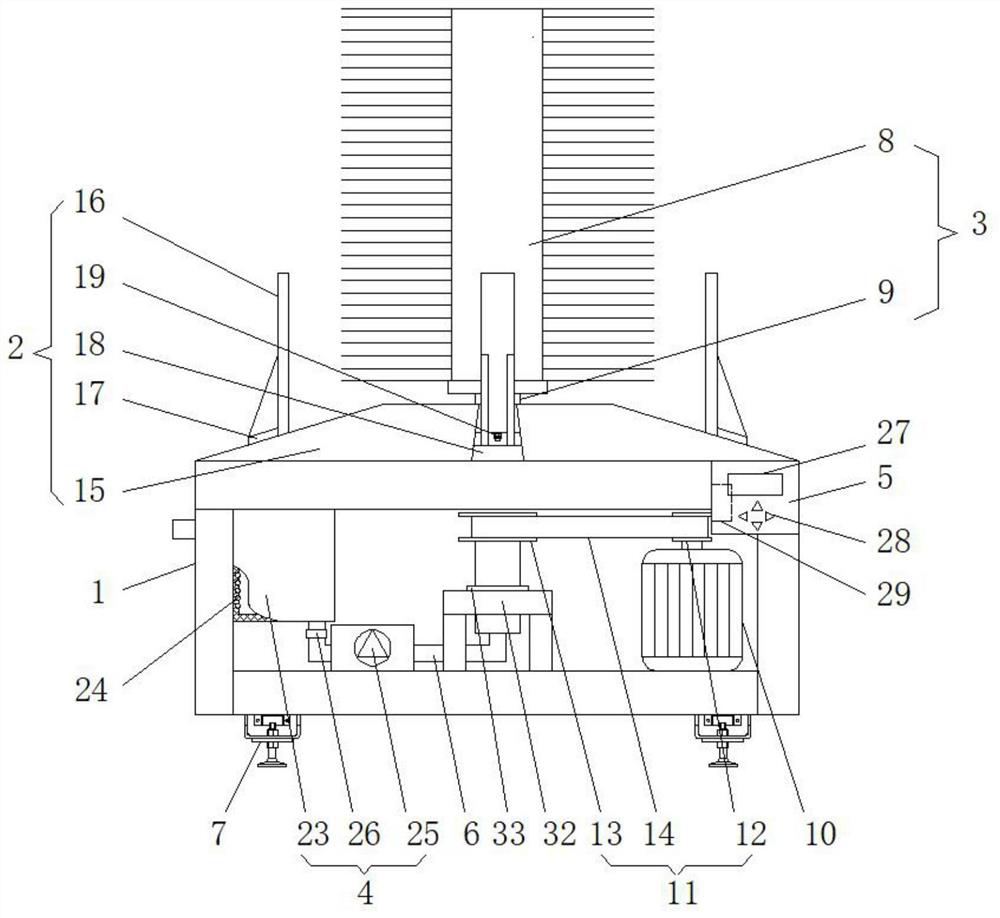

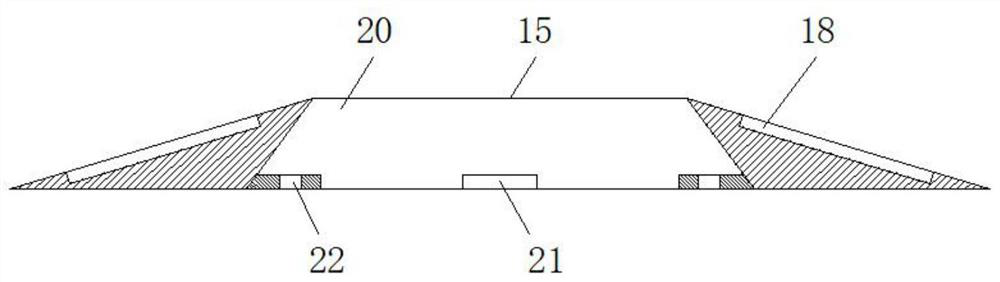

[0033] When the present invention is in use, a cleaning roller brush 8 of a suitable size is selected according to the internal diameter of the chemical tank, the chemical tank is placed upside down on the surface of the fixed bottom plate 15, and the position of the positioning seat 17 is adjusted along the guide groove 18, so that the movable clamping plate 16 It is closely attached to the outer wall of the chemical tank to improve the stability of fixing the chemical tank. The controller controls the drive motor 10 to work, and the drive assembly 11 is used to drive the central shaft 9 to rotate, thereby driving the cleaning roller brush 8 to clean the inner wall of the chemical tank. wash.

Embodiment 2

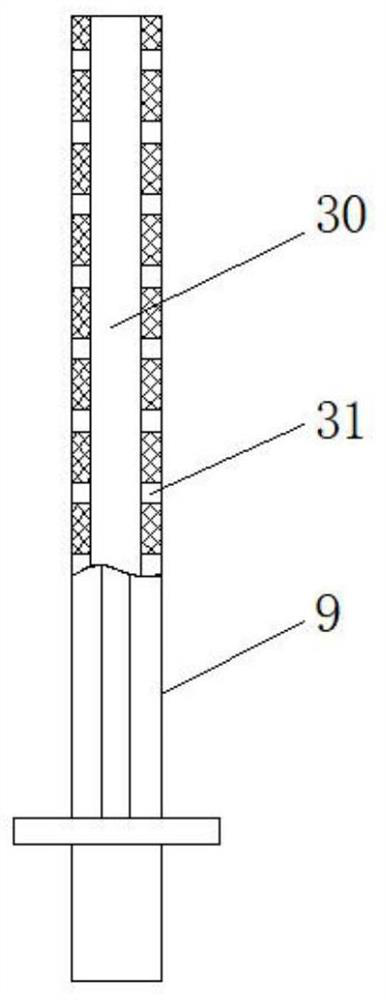

[0035] In the cleaning process, the present invention adjusts the temperature of the cleaning water through the controller according to the water temperature requirements during cleaning of different chemical tanks, uses the electric heating coil 24 to heat the water in the heating water tank 23, and the temperature sensor 26 measures the temperature of the flowing water. Monitoring, the water pump 25 sends the water in the heating water tank 23 into the central shaft 9 through the pipeline, and sprays it through the spray hole 31 on the surface of the central shaft 9, which is convenient for cleaning, and the waste liquid after cleaning is along the inner wall of the chemical tank. It flows to the surface of the fixed bottom plate 15 in the shape of a circular frustum and is discharged, which facilitates the cleaning work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com