An independent pre-screening and dust-removing mechanism for a two-way vibrating feeder

A technology of two-way vibration and feeder, which is applied to the cleaning method of tools, cleaning methods and utensils, and grain processing, etc., can solve the problem of poor dust removal effect, and achieve the effect of facilitating separation, improving the barrier effect and improving the dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

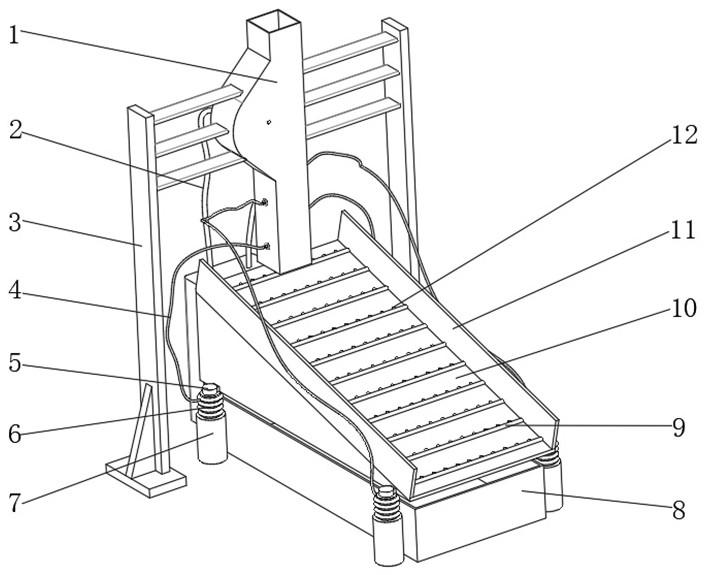

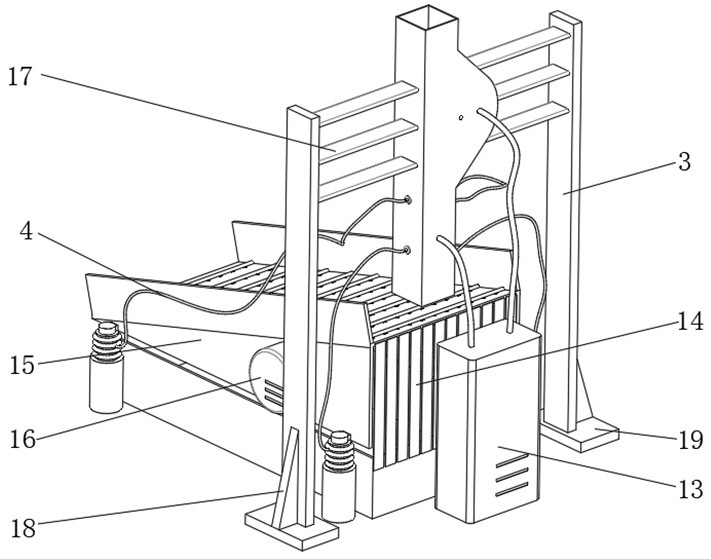

[0033] An independent pre-screening and dust removal mechanism for a two-way vibrating feeder, such as Figure 1-6 As shown, it includes a feed channel 1 and a pre-screen frame 15. The feed channel 1 is installed above the pre-screen frame 15 through a support assembly. The inner walls of the feed channel 1 are equipped with staggered hollow seats 27. The hollow seats 27 One end located in the feed channel 1 is bonded with a columnar air bag 21, and the other end of the hollow seat 27 is provided with a trachea joint 26, and the inner walls of both sides of the top of the pre-screen frame 15 are fixed with the same pre-screen plate 10 by screws. The top of the plate 10 is provided with evenly distributed second sieve holes 12; the outer wall of one side of the pre-screen frame 15 is fixed with a vibrator 16 by screws, and the outer walls of both sides of the pre-screen frame 15 are fixed with four pressing blocks 5 by screws. A supporting leg 7 is arranged below the briquettin...

Embodiment 2

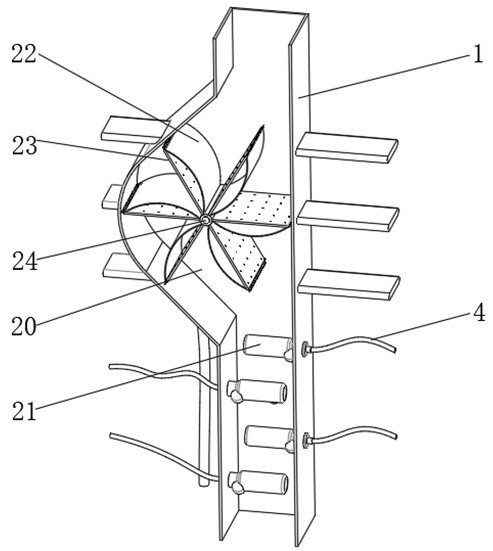

[0041] An independent pre-screening and dust removal mechanism for a two-way vibrating feeder, such as figure 1 As shown, in order to further improve the dust removal effect; this embodiment makes the following improvements on the basis of embodiment 1: the inside of the feed channel 1 is provided with an impeller chamber 20, and the inner walls on both sides of the impeller chamber 20 are rotatably installed by a support shaft 24 There is an impeller seat 28, and an evenly distributed impeller plate 23 is integrally arranged on the outer wall of the impeller seat 28. The impeller plate 23 is located above the columnar air bag 21. The other negative pressure end of the vacuum cleaner 13 is connected to Inside the impeller chamber 20 of the feed channel 1; by setting the impeller plate 23 and other structures, the material can be received when the material falls, and based on the weight of the material, the impeller seat 28 is rotated, and then the material is put down to achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com