High-flux super-hydrophilic/underwater super-oleophobic Janus membrane modification method

An underwater superoleophobic and superhydrophilic technology, applied in the chemical industry, can solve problems such as wetting, and achieve the effects of improving toughness, reducing energy consumption, and being easy to operate and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

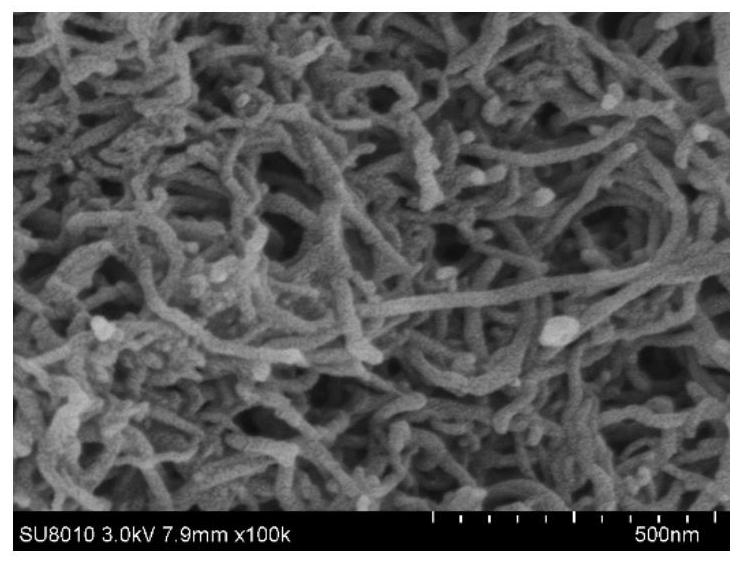

[0044] S1. Dissolve the hydrophilic carbon nanotubes in 5ml of absolute ethanol solution, sonicate for 60 minutes to disperse the material evenly, and prepare a carbon nanotube-ethanol suspension with a certain concentration;

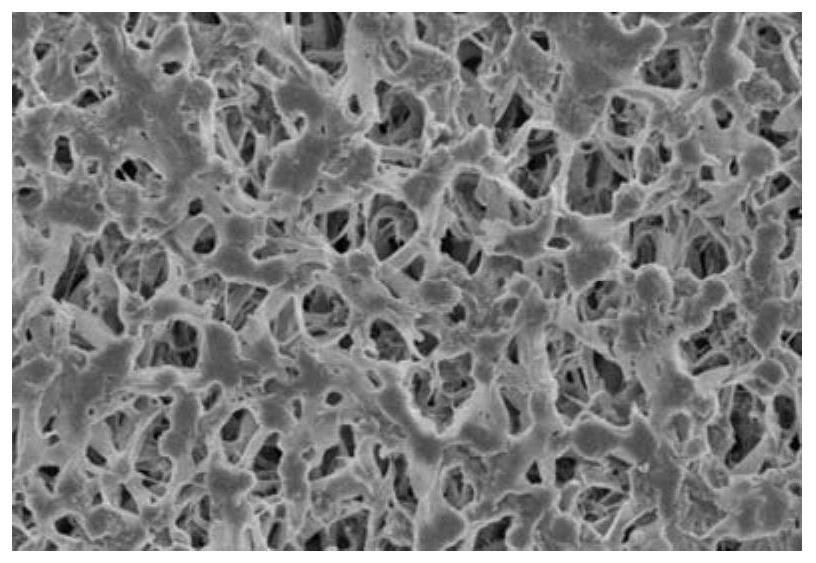

[0045] S2. Immerse the PVDF flat film in an ethanol solution, treat it with ultrasonic waves for 10 minutes, and place the loaded film in a constant temperature drying oven at 80°C for 24 hours;

[0046] S3. Use a vacuum pump to load 5 mL of the carbon nanotube-ethanol suspension prepared by S1 on the PVDF flat film of S2 under a negative pressure environment with a vacuum degree of 0.05-0.10 MPa. The deposition temperature is 25 ° C. The time is 60 minutes, the rotor speed is 400r / min, and then dried in a constant temperature drying oven at 60°C for 6 hours;

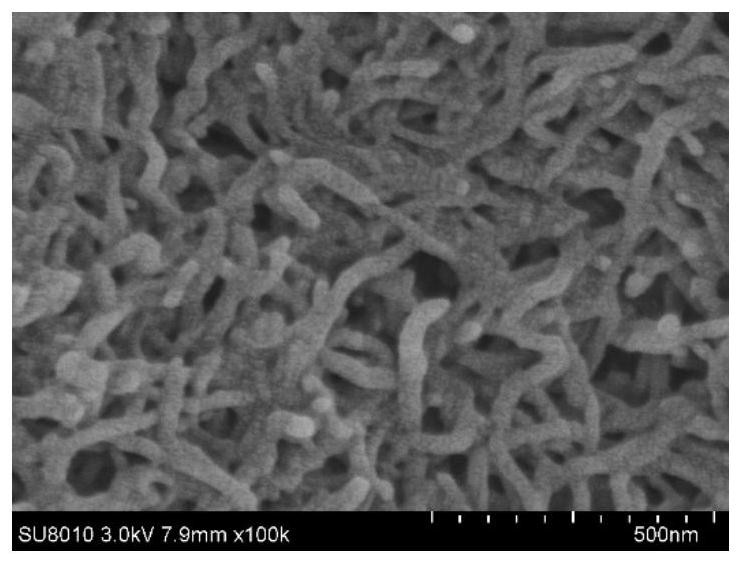

[0047] S4. Immerse the film material of S3 in the tris 8.5 solution of 2mg / L dopamine solution and 6mg / L polyethyleneimine solution at a constant temperature of 25°C, co-deposit at 400r / min for 6...

Embodiment 2

[0049] S1. Dissolve the hydrophilic carbon nanotubes in 5ml of absolute ethanol solution, sonicate for 60 minutes to disperse the material evenly, and prepare a carbon nanotube-ethanol suspension with a certain concentration;

[0050] S2. Immerse the PVDF flat film in an ethanol solution, treat it with ultrasonic waves for 10 minutes, and place the loaded film in a constant temperature drying oven at 80°C for 24 hours;

[0051] S3. Use a vacuum pump to load 5 mL of the carbon nanotube-ethanol suspension prepared by S1 on the PVDF flat film of S2 under a negative pressure environment with a vacuum degree of 0.05-0.10 MPa. The deposition temperature is 25 ° C. The time is 60 minutes, the rotor speed is 400r / min, and then dried in a constant temperature drying oven at 60°C for 6 hours;

[0052] S4. Immerse the film material of S3 in the tris 8.5 solution of 2mg / L dopamine solution and 6mg / L polyethyleneimine solution at a constant temperature of 25°C, co-deposit at 400r / min for 1...

Embodiment 3

[0055] S1. Dissolve the hydrophilic carbon nanotubes in 5ml of absolute ethanol solution, sonicate for 60 minutes to disperse the material evenly, and prepare a carbon nanotube-ethanol suspension with a certain concentration;

[0056] S2. Immerse the PVDF flat film in an ethanol solution, treat it with ultrasonic waves for 10 minutes, and place the loaded film in a constant temperature drying oven at 80°C for 24 hours;

[0057] S3. Use a vacuum pump to load 5 mL of the carbon nanotube-ethanol suspension prepared by S1 on the PVDF flat film of S2 under a negative pressure environment with a vacuum degree of 0.05-0.10 MPa. The deposition temperature is 25 ° C. The time is 60 minutes, the rotor speed is 400r / min, and then dried in a constant temperature drying oven at 60°C for 6 hours;

[0058] S4. Immerse the film material of S3 in the tris 8.5 solution of 2mg / L dopamine solution and 6mg / L polyethyleneimine solution at a constant temperature of 25°C, co-deposit at 400r / min for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com