Automatic chicken raising cage with automatic chicken discharging function and use method thereof

A chicken cage and functional technology, applied in the application, poultry industry, poultry cage or house, etc., can solve problems such as broiler injury, avoid injury, reduce costs, and improve chicken production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

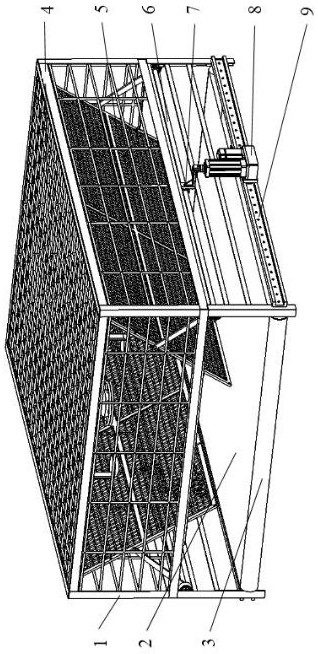

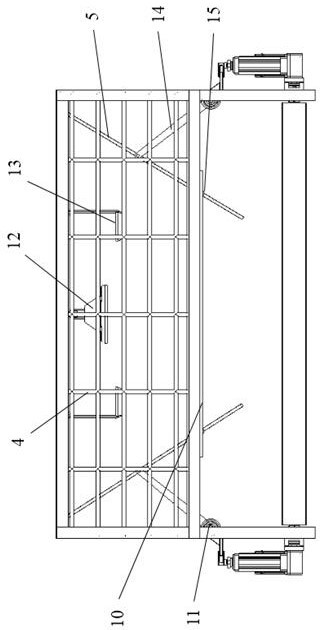

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0023] like figure 1 An automatic chicken cage with the function of automatic chicken feeding is shown, including a skeleton 1, and a cage bottom, cage top and cage side net 4 installed on the skeleton, the skeleton is welded by angle iron, and the cage top is a mesh type Structure, the bottom of the cage is provided with a number of manure leaking holes, a belt conveyor is arranged below the manure leaking holes, and a feeder 12 and a water feeder 13 are provided above the bottom of the cage.

[0024] The belt conveyor consists of two rollers 3 installed on the skeleton and a conveyor belt 2 connecting the two rollers 3, one of which is connected to an external motor, the conveyor belt 2 is located at the bottom of the chicken cage, and the shafts at both ends of the roller 3 are fixed on the spherical ball by fastening sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com